Often underestimated, agricultural tyres play several essential roles to which we do not pay much attention in general; yet by optimising certain settings you can considerably improve your tractor’s performance and boost its productivity.

The tyre is the main actor in transmitting power to the ground, making it your principal ally in the pulling power of your vehicle.

Mechanical settings, the height of the studs, wear and pressure are all elements which influence your daily work as well as the compaction of your soils, which can affect your profitability. By mastering certain techniques linked directly to your agricultural tyres, you will be able to optimise your productivity without too much effort.

The advice below will allow you to slow down wear and tear, preserve your soils and reduce your fuel consumption. It will also be useful to calculate the load that your agricultural tyres can bear and possibly help you to use dual tyres to improve traction, reduce the slip ratio and thus improve your yield.

1. The optimisation techniques linked to mechanics: from geometry to lead

To avoid premature wear to your agricultural tyres and take advantage of their performance for as long as possible, a few techniques linked to mechanics must be taken into account. With this in mind, in addition to adapting tyre pressure settings, you must also consider the lead and correct any misalignment problems.

Check the lead

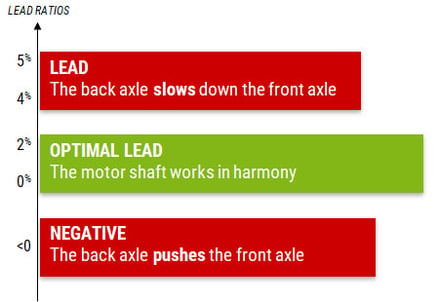

When the front wheels of your tractor tend to wear more rapidly than the back wheels, this can be linked to the wrong amount of lead. In other words, the front axle is not correctly synchronised with the back axle. In principle, the lead should be between 0 and 3% to allow your vehicle to transmit all its power.

CONSEQUENCE OF THE WRONG AMOUNT OF LEAD

If these percentages are not respected, there are two possible outcomes:

- The lead is above 4%: the back axle slows down the front axle = premature wear to the front tyres, steering problems…

- The lead is below 0% (lag): the back axle pushes too much compared to the front axle = alteration of transmission, considerable slippage at the back of the tractor, loss of efficiency of the front axle…

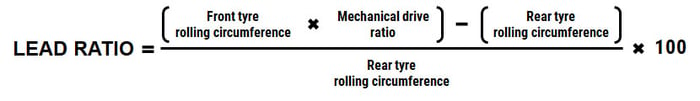

To avoid facing these mechanical constraints, you should calculate your lead using the following formula:

Lead calculation formula

Geometrical fault: adjust alignment and camber correctly

Among the main causes of wear to your agricultural tyres, geometric faults are the most frequent:

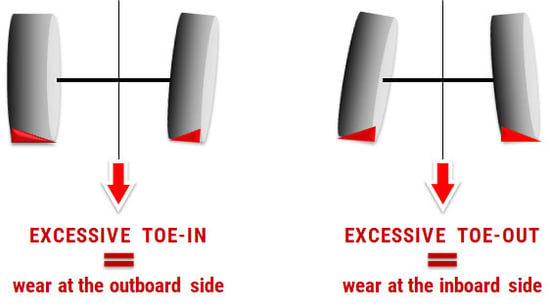

- Misalignment: this involves and incorrect alignment with respect to the centreline of the axle. Ideally, your tyres should be perfectly aligned and parallel to your tractor.

- Camber problem: this involves the tilt of the wheels in relation to the ground. When you check, ensure that your tyres are perfectly vertical and as flat as possible on the ground.

Misalignment

In all cases, it is advisable to check the geometry of your agricultural tyres regularly in order to ensure that they do not wear too rapidly. With a little patience and adapted measurement equipment, you can carry out the inspection yourself to save a few more euros.

When adjusting the parallelism of your tractor,

take into account the effort demanded from your front axle and allow for a little toe-out (1 – 1.5 mm)

2. Techniques to avoid soil compaction

The use of ill-adapted tyres encourages soil compaction, which inevitably leads to a loss of productivity in the range of 20 to 50% over several years.

To optimise your yield, there are several solutions such as adapting your tyres to the type of ground to avoid further compaction. To do this, you first need to establish the type of compaction:

- Surface compaction: this is essentially due to the incorrect adjustment of your agricultural tyre pressure. Therefore, make sure that you check your tyre pressure regularly.

- Deep compaction: is caused essentially by too heavy a load at the level of the axle. In this case, don’t hesitate to mount wider tyres with a larger volume of air or duals if necessary.

In all cases, the simplest solution to avoid soil compaction is to use low pressure tyres. These are designed to preserve your soil permanently, thus avoiding recourse to any decompaction operations.

Furthermore, low pressure tyres using VF technology can bear a heavier load (+40% compared to classical tyres) without compacting the soil.

With a larger tyre-soil footprint and a higher load index, VF agricultural tyres guarantee optimal productivity as well as fuel savings.

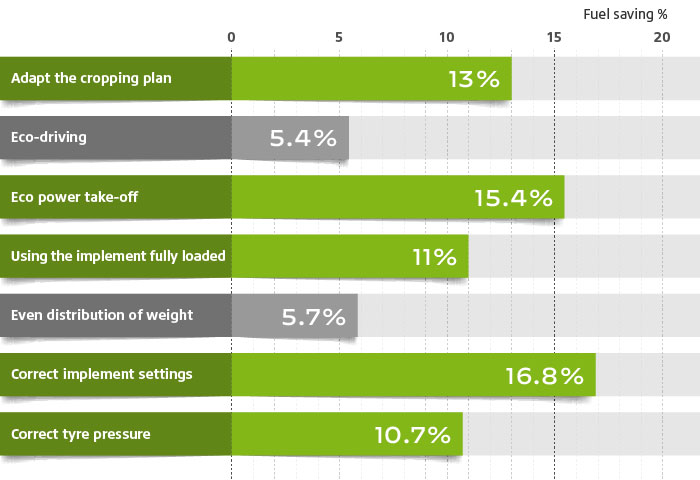

3. Techniques to reduce fuel consumption: 5 fuel-saving tips

The price of fuel for tractors and other agricultural machinery increases regularly, which has a major impact on your operating costs. There are also good techniques to adopt to reduce fuel consumption. This involves four essential elements: the tyres, the type of work, the speed and the load.

1. Adapt the pressure of your agricultural tyres

Incorrect agricultural tyre pressure adjustment will only increase your fuel consumption. You must therefore adapt tyre inflation pressure to the type of work:

- On the road: don’t hesitate to increase your inflation pressure slightly to reduce the contact surface with the asphalt. Resistance will be lower, which requires less power and therefore less fuel.

- In the field: inversely, it is advisable to reduce the pressure of your tyres to avoid slippage and loss of grip. Less tractive force will be required and therefore less fuel consumption.

2. Use tyres that are adapted to your main activity

Ploughing, transport, livestock management… each type of use of your vehicle corresponds to specific tyres.

To reduce your consumption, you should begin by equipping yourself with tyres that are adapted to the main activity carried out by your tractor.

For example, for regular work in the fields, it is best to use low pressure tyres that are larger than the original tyre mount.

Even if low pressure tyres are often expensive, this is made up for by the fuel savings generated in the long term, the soil preservation, the decrease in working time, less driving related fatigue and an increase in production.

3. Reduce the working depth

In the case of heavy work such as harrowing or ploughing, it is not necessary to work deep down.

Tests have proved that by reducing the working depth by around 8 cm, it is possible to save on average 25% of fuel. There are different solutions available to you for this:

- Work the soil regularly.

- Avoid excessive compaction.

- Use low-pressure VF tyres.

4. Limit your speed on the road

By permanently chasing after time, you merely increase your fuel consumption, above all if you have several kilometres to drive on the roads every day. In a year, the ten or so minutes gained on each trip are worth nothing compared to the fuel saved by reducing your speed by an average of 10 km/h.

5. Calculate the ideal weight distribution

Calculating the distribution of weight is essential when working in the fields. The pulling power required has a direct influence on your fuel consumption. If the calculation is wrong, your machinery will be imbalanced and will not be able to use its full power.

Whatever the case, it’s best to increase the load on the axles by distributing the load as evenly as possible to optimise grip and avoid slippage, which will logically reduce your consumption.

4. Techniques linked to load: balance out the weight evenly

An overloaded trailer has unexpected consequences: agricultural tyre deformation and/or risk of interior cracks, soil compaction, progressive loss of yield …

To ensure the efficiency of your work, balance out the load over the tractor tyres and your trailer. This weight distribution will condition:

- Your vehicle’s tractive force.

- Soil preservation: development of your crops.

- Wear to your agricultural tyres: more or less rapid.

- The balance of your tractor and trailer: your safety.

The work consists in spreading the weight taking into account the characteristics of your agricultural tyres. If they have the same diameter, they will bear the same weight. However, there are some particular cases:

- Tractor with two-wheel drive: to optimise the efficiency of the steering axle, you must place 20% of the total load on the front axle.

- Tractor with unequal four-wheel drive: a load distribution of 40-60 must be adopted, with 40% at the front and 60% at the rear.

5. Techniques linked to traction: use dual agricultural tyres to improve productivity

Among the different techniques used to optimise your productivity, improving traction is essential and using dual agricultural tyres is the best solution. This is all-the-more true when you use a very powerful tractor which is relatively heavy, with wide, heavy implements.

Duals should reduce the load to the ground and make it possible to improve traction, avoid excessive soil compaction and improve your overall productivity.

When using duals, there are four possible configurations which are differentiated by the tyre size and spacing.

Depending on the type of work and crop, you may opt for:

Dual tyres of the same size

Association of wide tyres on the outside and narrow tyres on the inside

Hoeing, narrow tyres on the outside and wide tyres on the inside

Double furrow wheels

The 4th configuration with double furrow wheels is highly appreciated as it makes it possible to preserve the soil without impacting crops in rows such as vegetable crops, beetroot, corn…

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc.

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles which are listed by order of popularity:

- Your braking capacity depends directly on your tractor tyres

- +20% extra fuel consumption linked to tractor tyre slip

- Farm management: -30% less consumption for your tractors

- Fuel savings of 10% to 20% with good tractor tyres

- +55% more load on my harvester with better harvest tyres

- Manage your pressure to the ground to make your agricultural tyres last longer

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *