For agricultural contracting companies, investing more in tractors to obtain more efficient machines is a particularly profitable choice, especially if you have a large fleet. Equipping your vehicles with tyre inflation systems is clearly a way of making real savings, but it also helps to build customer loyalty. The main argument is soil preservation on your clients’ land together with quality work. The ability to work quickly with better traction will also be appreciated.

In short, an additional piece of equipment to put you in a win/win situation and which, in the end, benefits everyone.

This article sets out the main reasons to turn to tyre inflation systems for your agricultural contracting company.

1. Central tyre inflation systems: The best choice to ensure that your operators adapt tyre inflation pressure regularly

Tyre pressure adjustments are essential to preserve your tyres, travel long distances on the road to reach different sites and avoid soil compaction in your clients’ fields.

There would be a negative long-term impact if your clients were to realise that after your intervention their land appears to be compacted. This could lead to additional decompaction costs to get quality soil back.

You therefore have a responsibility to preserve their land and it’s often difficult to pass on the information to your operators to be sure that the work is carried out in the best possible conditions.

Install a central tyre inflation system to ensure that the pressure is always right

An agricultural company contractor is alone in his tractor and has to make decisions alone to ensure good service to the clients.

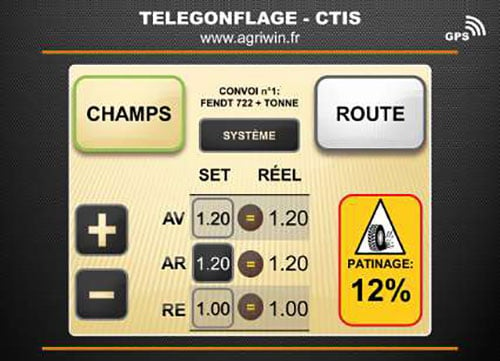

If the company makes the job easy with an automatic inflation system installed in the tractor and the operator can adjust pressure from within the cab, he will always make the choice to work at the right inflation pressure. Especially if this means he wastes no time getting out of the tractor to inflate or deflate the tyres manually.

And he will be even more inclined to do this if the change in pressure, which is very simple to carry out, gives him better traction.

He knows he will be able to finish the job quicker. Another reason to adopt the right pressure in all circumstances.

CTIS control box in the cab

CTIS control box in the cab

Reducing inflation pressure from the cab is a relatively quick process which enables you to reach the desired pressure rapidly when arriving in the field.

However, increasing pressure with a central inflation system when you go back on the road is a longer process (depending on how powerful your compressor is).

To really protect tyres against wear, it is absolutely essential to wait until the inflation process is finished before beginning to accelerate on the road.

2. Better traction while preserving your clients’ soil

The right pressure to optimise traction

Reducing pressure when you arrive in the field allows you to increase the tyre footprint on the ground and increase the contact patch of the lugs, which will have a better grip thanks to the larger lug and tread contact area.

With each rotation of the wheel the contact is optimal and transmission of engine power to the ground is better.

With better grip, traction improves and in a field of several hectares you will have saved at least an hour by the time the job is done.

The right pressure to preserve your clients’ soil

A central tyre inflation system allows your operators to reduce pressure to less than 1 bar on entering the field, without having to stop. The contact patch with the ground increases and the soil bearing capacity improves considerably.

If your client does not have this equipment, he will be pleased to notice that when he outsources to your company the soil in his field is certainly less compacted than when he uses his own machinery.

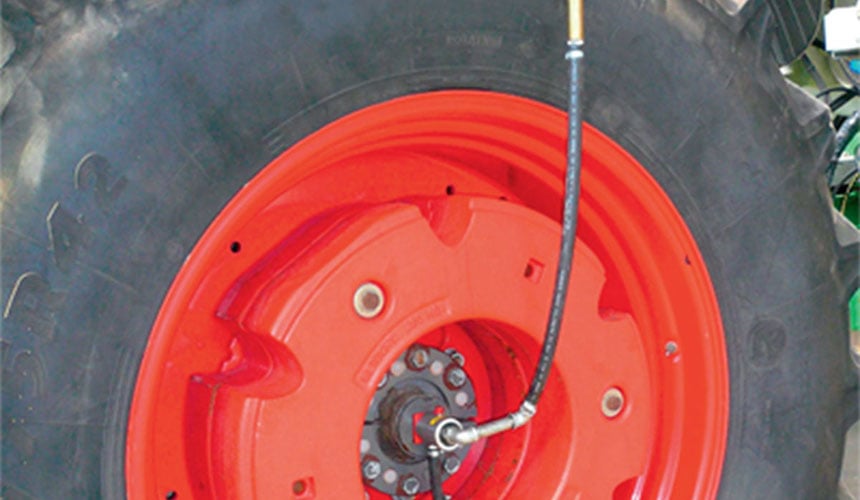

Rotary joints to ensure the flow of air

Rotary joints to ensure the flow of air

between the rotating wheel and the fixed axle

3. Fuel savings by reducing slip

You don’t always have the choice of working in good weather conditions and if you have many campaigns during wet periods, you will know the extent to which slippage can slow down your work rate, or even damage your soil in certain extreme cases.

Slippage is often linked to incorrect pressure adjustment

A certain amount of slip is necessary to transmit tractive force, at around 12%. On the other hand, more than 15% slippage leads to horizontal sliding of the topsoil and damages its structure. In addition, the actual distance travelled by the tyre is greater than the distance travelled by the tractor. This results in excess fuel consumption as well as premature wear to the tyres.

Change in tyre pressure test in the same field

Change in tyre pressure test in the same field

on the left 1 bar = no slip,

on the right 1.25 bar = excessive slip.

4. Saving on tyres by limiting wear

The main cause of wear to agricultural tyres is inflation pressure which does not correspond to the load or to the ground on which the tractor is driving. If inflation pressure is too low on the road, the abrasive asphalt wears aware the rubber rapidly and inversely, if the inflation pressure is too high in the fields, slippage will increase and lead to more sliding and more wear to the rubber.

A central tyre inflation system is the ideal way to combat wear linked to incorrect inflation pressure. As pressure is always perfectly adapted to the type of ground and the load, the tyre is always used in the best possible conditions.

The rubber wears less quickly, leading to thousands more hours of use before having to replace the tyres. The savings are significant in the long-term with sets of tyres which last much longer.

5. VF tyres + CTIS: the winning duo for more load and less pressure

VF (Very Improved Flexion) tyres allow you to increase the load up to 40%

They are made with very high-tech components. They have a more supple sidewall and a more resistant structure which allows them to carry 40% more load than a standard tyre (with the same inflation pressure). This allows you to pull wider implements to reduce the number of passages across your land.

The natural qualities of these high-tech tyres combined with a remote inflation system would allow an agricultural contracting firm to boost yields with heavier loads, more traction and a quicker work rate, while reducing fuel consumption and preserving the soil.

Unlike standard agricultural tyres which cannot be inflated to less than 1.2 bar, VF tyres are designed to be used at less than 1 bar, despite the bonus load, and are therefore highly effective in preserving your soils.

Central inflation system on the tractor and its trailer

Central inflation system on the tractor and its trailer

Is investing in a CTIS really cost-effective?

Despite the high acquisition cost which might deter a small farm with only a few machines, this type of investment makes perfect sense for an agricultural contracting company which manages a large fleet, and all the more so in that it brings added value to the services offered.

This investment will really make a difference to your bottom line thanks to fuel consumption and your tyre replacement rate.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc…

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles which are listed by order of popularity:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *