Changing a tractor tyre is always a tricky, technical operation, not especially complex, but problematic due to the weight and size of the tyres.

Having the right tools is vital, which is why it is often simpler to turn to professional tyre fitters who carry out this task on a daily basis. They will know how to avoid all the traps linked to mounting, which can result in a tyre that is unfit for use if you do the job yourself and do not use your tools correctly.

Here are a few cases where the tyre may be unfit for use following faulty mounting:

1. Problem during the preparation and handling of the tyres

A minimum amount of equipment is necessary to dismount a tyre, such as:

- a lifting jack,

- axle stands,

- chocks,

- a lifting bag,

- adapted levers,

- bead lifting tool,

- specific lubricating paste,

- wire brush,

- valve,

- tyre valve deflator,

- air compressor,

- technical data.

Without this equipment, the operation should not be undertaken as it could be dangerous and take too much time, whereas a professional can do it for you rapidly.

The first problem encountered is generally linked to the safety of the site:

To begin the operation, the tractor must be placed on a perfectly flat surface, preferably concrete.

You must also have chocks and axle stands at all costs in order to avoid the tractor slipping or moving during the mounting or demounting operation.

The jack must obligatorily be positioned as indicated by the manufacturer, so you must refer to the technical documentation to identify these positions.

The jack must be used only to lift the tractor and never to hold your tractor in place once raised.

The role of the axle stands is to ensure overall stability, to avoid a fall due to a faulty jack or movement linked to vibrations caused by the mounting and demounting operations.

Tractor tyres are very heavy and this is the difficulty that the operation faces. On average, front tractor tyres effectively weigh between 50 and 100 kilos and rear tyres may weigh more than 350 kilos.

The risk of accidents due to a slipping tyre which you try to prevent from falling is significant and requires the right equipment to ensure lifting operations are carried out in total safety.

Don’t hesitate to use a wheel lift dolly, which will allow you to mount your tyre at exactly the right height in perfect safety.

2. Problems linked to manual mounting and demounting

For demounting

Once there is no longer any weight on the tyre, you must deflate it by opening the valve, then to begin demounting your tyre, remove the bead from the rim, beginning at the specific groove indicated for this purpose.

There is a lot of movement in this area. In general, this zone is handled more to begin the removal process, which can cause a weakness, if precautions are not taken.

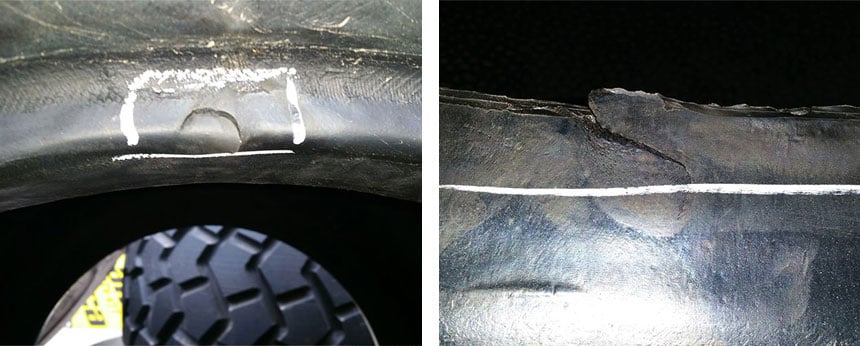

If you use manual levers, be very careful in this area because this can result in the bead heel breaking, just at this spot. In this case, your tyre will unfortunately be totally unfit for use.

The use of levers is essential during manual demounting.

The number of levers used must be sufficient to remove the bead progressively 10 cm by 10 cm over an extensive area so as not to force the bead in one spot only.

Placing the levers incorrectly may cause a flattening, tear or break to the bead. If the damages caused by the levers is extensive, it may be necessary to replace the tyre.

For remounting:

- Before remounting the new tyre on the rim, make sure that it has no defects (break, crack).

- Clean the rim seats with a wire brush to remove rust and dirt.

It is very important to be especially careful when cleaning the grooves on the edge of the rim. If they are not clean or if there is too much rust, this can change the diameter of the rim or result in slipping or bead instability. - Then replace the tubeless valve or inner tube if working on a tyre with an innerliner.

3. Problems linked to mechanical mounting and demounting

The use of an automatic tyre changer can cause damages to the tyre if the operation is not carried out properly.

Lubrication of the beads is essential during this operation and is often done too quickly or with insufficient care.

If the bead is not correctly lubricated, it is difficult to get it past the edge of the rim well, then it does not lie straight at the top of the rim flange, thus squashing the bead heel.

The bead area is essential to ensure airtightness, so this can result in air leakage or cause the tractor to sway when driving.

It ensures the connection between tyre and rim and, as such, the transmission of torque. If it is badly positioned, the likelihood of the rotation of the bead on the rim seat is high.

4. Problems during inflation of the new tyre

Positioning of the beads

Lubrication of the beads is vital to ensure correct positioning during the inflation process.

It is essential to use a product that is specially designed for this type of operation and never to use vegetable or mineral oil, or soapy water.

It is also necessary to lubricate:

- the rim seat,

- the grooves,

- the base of the rim.

If the tyre is not perfectly centred during the initial inflation process, it will always be preferable to let the air out, relubricate the beads and start the inflation process again.

There is a pictogram on the tyre which indicates the maximum inflation pressure, in general 2.5 bars.

There is a pictogram on the tyre which indicates the maximum inflation pressure, in general 2.5 bars.

If the mounting is not correct during inflation, the installation of the beads may lead to the tearing of the bead wire during the pressure surge and make the tyre unfit for use.

Inflation process

The most serious accidents occur during inflation. This operation is the most dangerous, so it is important to keep your distance during the inflation process. A single moment of inattention, linked to the use of a telephone for example, incorrect mounting or positioning of the tyre, can lead to bursting, sometimes resulting in serious injuries.

Make sure that you are never in line with the rim facing the tyre during the inflation process.

The safety position is at a safe distance from the tyre in line with the tread at the rear of the tractor for the rear axle or in line with the tread of the front tyre for the front axle.

5. How to avoid the hazards of mounting new tyres

You have invested in tyres which are often costly, so it seems logical to entrust fitting them to professionals to save time and avoid damaging your new tyres due to handling errors.

It takes a long time to replace your tyres if you don’t have the right equipment or experience for this type of operation.

Your tyre dealer is often the best partner to carry out this operation correctly. Don’t hesitate to talk to him about it, even if you have decided to do the job yourself, as advice from a professional may be useful.

To take it a step further and increase the profitability of your farm, here is an ebook, downloadable for free, which explains the essential role of your tyres in the optimisation of your productivity.

Most people who read this article have also read some of the following articles:

- Info to help you know your agricultural tyres better and make savings

- Do you know the rules for storing your farm tyres correctly?

- The 3 best techniques for storing your agricultural tyres

- Do you know how to read all of the indications on your tractor tyres?

- All the secrets of tractor tyres, agricultural tyres or farm tyres

- Understanding the manufacturer’s technical information on agricultural tyres

- How to check the condition of your harvester tyres before the harvest

- Golden rules for managing tyre breakdowns during the harvest

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *