Ballast is essential to improve performance levels and the efficiency of your work. However, it is important to bear in mind that the load bearing capacity of your agricultural tyres has its limits. Taking account of these limits is decisive in terms of how long your tyres will last, soil preservation and the optimisation of your operating costs.

Ballasting, or adding extra weight to your tractors is a common practice which aims to improve the stability and efficiency of your tractor, in particular when the rear implements are heavy. This rebalancing operation is often carried out by adding mass to the front lift, especially when the implements are exerting considerable pressure to the tractor’s rear axle.

However, good judgement is required when ballasting your tractor. Too much ballast which takes you beyond the load capacity of your tyres can lead to premature wear, or even damage your equipment. It is therefore crucial to ask a few important questions.

In this article we will look at 7 important points that will help you manage your tractor ballasting operations more efficiently as well as their impact on your agricultural tyres.

Good ballasting can optimise traction and productivity, while avoiding overloading and potential damages.

1. What are the consequences of overloading my tractor tyres?

Each agricultural tyre model is made for a precise use with limits in its capacities that are linked to its design.

Manufacturers have the load index marked on the tyres, fixing a limit that must not be exceeded.

Respecting this limit is essential if you wish to preserve the durability of your tyres, the safety of your combination vehicle and protect your soil.

Overloaded tyres linked to the weight of implements, trailers that are too heavy or excessive ballast may have several harmful repercussions:

Irreversible equipment damage

Excess load may lead to lateral deformation of the tyres’ sidewalls, thus increasing the risk of internal breaks in the casing, defects or punctures, especially with standard tyres which are not technically designed to resist heavy loads.

Tyres that are too frequently overloaded run the risk of becoming irreversibly deformed and needing to be replaced prematurely.

Soil damage

For soil protection purposes, it’s always going to be preferable to make the machines as light as possible, as excess load has a significantly negative effect on soil fertility.

On soft soil, heavy loads will require more tractive force, causing the tyres to sink down into the arable layer of soil and cause deep soil compaction.

Accelerated wear

The deflection and crushing of the tyre due to excess load accelerates wear. To offset the load, it is necessary to increase the inflation pressure, which in turns makes the slip ratio higher and leads to rapid wear to the tread.

A reduction in productivity

Too much load reduces your productivity, increases rolling resistance and slip, thus increasing fuel consumption while decreasing your work speed.

These two combined effects lead to an overall decrease in productivity and in your yields over the year.

An increased risk of accidents on the road

If the total mass of the combination vehicle is excessive for the tyre size, your security will be compromised, because overloaded tyres increase the risk of skidding in the bends or when braking and a loss of control of the trailer, especially in bad weather conditions.

2. Bad ballasting: what are the risks for my tractor tyres?

Ballasting, which is often unavoidable to optimise tractor work, can have negative consequences if it is not adapted to your tyres and the precise load that they can carry.

If the implement that you wish to use is not adapted to your engine power and tyre size, there is no point adding additional front ballast to try and balance out the weight. You will only increase the overall weight of the combination vehicle with all the risks and disadvantages linked to overloading described in the preceding paragraphs.

Risks linked to excess ballasting for your agricultural tyres

Excess load on agricultural tyres can lead to problems affecting both the productivity and the integrity of the equipment.

Overloading resulting from excess ballast, an incorrect load distribution or inappropriate water ballasting can cause excess fuel consumption, rapid wear or irreparable damage to the tyres, as well as excess soil compaction which is harmful to crop development.

In addition, it can cause mechanical damage if you do not respect your tractor’s hydraulic lift capacity, such as the front axle breaking, leading to high repair or replacement costs.

For work that requires high engine torque and as such maximum tractive force, the power to weight ratio of your machine must always be respected (for information 49kg per horsepower).

It is therefore crucial to control the overall weight borne by your tractor tyres, to avoid these costly risks and maintain tractor efficiency.

The drawbacks of insufficient ballasting

Inversely, insufficient ballasting affects tractor handling capacities.

If the weight of the tractor is not adapted to the weight of the implements used, this can cause an imbalance, with insufficient adherence of the front axle and an overloaded rear axle. This imbalance increases the slip ratio, slows down the work rate and accelerates tyre wear.

The insufficient front ballasting affects the handling of the tractor, in particular when changing direction on heavy soil.

Excess slip due to inadequate ballast can damage the soil structure, reduce work efficiency and increase fuel consumption. Lastly, insufficient ballasting, particularly with water ballasting, can prevent the trailer from being properly balanced, especially in the case of heavy loads.

3. Why and how do you ballast your tractor tyres or your agricultural tyres?

Ballasting agricultural tyres improves the efficiency of your work. This practice aims to optimise your machine’s traction, especially if your tractor is light and heavy implements requiring a lot of torque are used at the rear of your tractor.

Use of ballast allows you to improve the adherence of your combination vehicle (tractor + implement). This helps avoid excessive slip, improves stability and guarantees an optimal performance from your machine, whatever the type of ground.

There are different ballasting methods:

- The most common is the use of metal weights placed on the tractor’s front lifting system, which is particularly efficient in case of heavy loads on the rear axle.

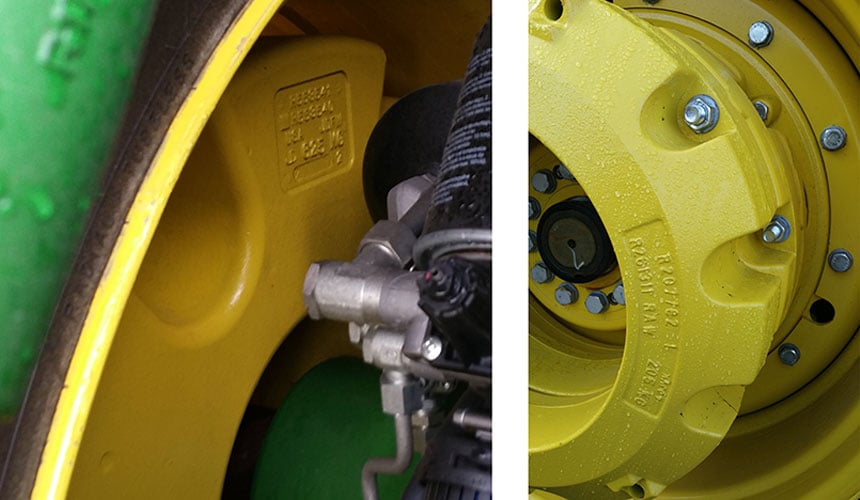

- Additional weights are also frequently added to the tractor wheels. These consist in metal weights fixed at the level of the rims. This solution avoids having to use the front lifting system when you need to use an implement at the front.

- And lastly, there is water ballasting, an economical method which consists in filling up the tyres with water to increase the tractor mass.

But beware, whatever the method used, ballasting must be carried out taking account of the load capacity of the tyres and the manufacturer’s specificities.

Pressure recommendations for the tyres must be respected to avoid problems of overloading, which could affect the durability of the tyres and the tractor’s mechanical safety.

4. Beware of the load transfer to my tractor tyres

The load transfer to the tractor tyres is one of the most important aspects to take into account for a correct ballasting operation. The purpose of additional ballasting is essentially to rebalance the weight between the front and rear axle in order to use the full capacity of the four drive wheels and therefore improve traction and tractor performance.

Consequences of an overloaded axle

An abnormally loaded axle can have very negative consequences for your agricultural tyres.

If you increase pressure to compensate for the excess load, this will encourage slip, especially on loose soil, because high pressure and a heavy load make the tyre sink deeper into the earth. This will lead to an irreversible deformation of the casing faced with the tractive effort, which may lead to internal breaks.

It is therefore vital to stick to the recommended load levels indicated by the manufacturer in the load index marked on the tyre’s sidewall. This load includes the combined weight of the tractor, the implement or the ballast, as well as the load transfer linked to drawn implements.

Identify the exact mass for better management of the load transfer

It is essential to know the tractor mass and the exact weight of the implement in order to define the quantity of ballast necessary and adjust inflation pressure accordingly, especially when you change implements.

The distinction between transport by road (raised implement) and work in the field (drawn implement) is important, because the load transfer varies considerably between these two situations.

Each tyre has a specific load index and it is important not to exceed the maximum load transfer that the rear axle can handle to avoid damaging the tyres.

5. What is the right weight distribution on your tractor tyres?

The right distribution of mass in relation to your tractor tyres guarantees your safety, the balance of your combination vehicle, motricity and the protection of your equipment and the soil.

An appropriation distribution of the load transfer to the tractor is essential to ensure the efficiency of the tyres and avoid excess fuel consumption.

Distribution of mass on four-wheel drive tractors with different tyre sizes

A distribution of 40% to the front and 60% to the rear is recommended. It is important to take into account the weight of the implements which generate a significant load transfer to the rear axle, then add mass to the front to rebalance the trailer axles. You then need to check overall mass and ensure that the tyres have the capacity to cope with this amount of load.

6. Is it best to choose water ballasting for my agricultural tyres or metal weights?

The choice between water ballasting or metal weights for the tractor tyres is an important decision when it comes to optimising tractor performance, taking into account the economic side.

Water ballasting of tractor tyres

Water ballasting is a less costly solution than the use of metal weights. If you wish to use permanent water ballasting, don’t forget to add antifreeze with a proportion of 15% of the volume of water. This type of ballasting has significant benefits:

- A very economical solution allowing you to add up to 4 tonnes almost for free.

- An even and proportional distribution of weight to the tyres.

- No risk of mechanical breakdown of the front axle.

Ballasting using metal weights:

This type of ballasting provides:

- Extensive flexibility with the possibility of adjusting the number of weights required.

- A better possibility of adapting the load distribution between the front and rear of the tractor.

Nevertheless, ballasting using metal weights requires a complex installation operation involving lifting apparatus due to the additional weight.

Precise control procedures are also necessary to avoid overloading which can affect the durability of the tyres or lead to mechanical problems.

7. What are the drawbacks of water ballasting tractor tyres?

Although water ballasting is a very economical solution for stabilising your tractor, this practice has severl major drawbacks which must be taken into account:

Ballasting unsuitable for the actual trailer mass

Water ballasting is too even; it does not take account of the weight of the implements and as such only has a partial effect of rebalancing the combination vehicle, either representing too much weight if the implement is light, or not enough if it is heavy.

It often needs to be completed by the use of metal weights on the front lifting system to obtain a perfect balance for your combination vehicle. This means that you have to carry out two ballasting operations where just one would have been enough.

This type of ballasting implies a permanent dead weight

Water ballasting leads to a permanent dead weight on the tractor. This can be useful when it’s necessary to make the axles heavier to improve traction, but this additional weight leads to higher fuel compaction throughout the year, even in situations where ballasting is not required.

Time needed for the ballasting process

The process of inflating the tyres with water is relatively long and requires several hours to complete, and the same goes for the deflation process if you don’t need the ballast anymore.

On the other hand, the addition of metal weights can be done more rapidly, in only about fifteen minutes.

More frequent pressure control

Due to the reduction in the volume of air in the tyres, water ballasting requires more frequent pressure checks.

The slightest loss of air can lead to a large decrease in pressure, which can be damaging in numerous circumstances.

Unsuitable for high speeds

Water ballasting is not ideal for transport at speed by road or working fast in the fields.

If you travel quickly, it can cause a swaying effect linked to the movement of the water mass, generating a pitching effect when the tractor is cornering and destabilising the combination vehicle.

CONCLUSION

Adequate ballasting of agricultural tyres is essential to improve the stability of the tractor and ensure efficient traction, especially when your implements are heavy and require a lot of torque.

Adding weights to the front helps to rebalance the load, keep control over slip and improve the traction capacity.

This process, if correctly managed, not only ensures your safety but also protects your equipment and your soil.

By taking the time to check and adjust ballasting as well as the pressure in the tyres based on the different uses of the tractor, you will optimise traction, productivity and the wear life of your tyres, while reducing costs linked to slip, fuel consumption and tyre wear.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc.

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles:

- How and why to ballast your tractor tyres or agricultural tyres

- What are the consequences of excessive weight on my tractor tyres?

- Distribution of weight: ballast with liquid in the tyres or cast iron weights

- What is the right load distribution for my tractor tyres?

- What are the disadvantages of using water ballast in tractor tyres?

- Incorrect ballasting: what are the risks for my tractor tyres

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *