When you decide to change tyre size, it’s to obtain more longitudinal traction, less compaction and therefore better care for your soil. If you make the decision to increase tyre size, it’s to improve the performance of your tractor, but be careful in terms of the mechanical performance of agricultural tyres…

Behind this little known notion lies the question of lead, which is an essential aspect for the smooth running of a four-wheel-drive tractor with different sized front and rear tyres. Whether the lead ratio is too high or too low, incorrect lead can cause major mechanical problems with power transmission.

This mechanical performance is directly linked to tyre size, but also to the dynamic rolling circumference which varies depending on wear, brand, pressure or load. So before investing in new large-dimension tyres, it’s best to have a clear understanding of this technical notion in order to avoid costly errors.

In this article, we look in detail at what the mechanical performance of agricultural tyres really means, how to manage it and what solutions you have to ensure optimal synchronisation between the front and rear axles of your tractor. Your productivity and the durability of your equipment depend on it.

1. Explanations on mechanical performance linked to agricultural tyres

Why talk about mechanical performance?

Optimal mechanical performance in agricultural tyres depends on a precise dimensional balance between the front and rear of the tractor, to guarantee an optimal lead ratio. Expressed as a percentage, it represents the difference in rotation speed between the front wheels (which are smaller and turn faster) and the rear wheels.

An ideal lead ratio of around 2.5% allows the front axle to pull slightly more, ensuring perfect synchronisation and maximal traction when four-wheel-drive is engaged.

To calculate the lead ratio, you need to know:

- Your tractor’s drive ratio

- The exact rolling circumference of each tyre.

Once you have this information, you can apply the following formula:

When you change tyres, it is essential to recalculate the lead ratio, because the rolling circumference can vary from one type of tyre to another or from one brand to another, even if they have the same nominal dimensions.

What is the link between lead and the tractor’s mechanical components?

On 4WD tractors with different sized wheels, the rotation speeds are different. If this is not managed correctly with an unsuitable lead ratio, it will cause mechanical strain. If the traction in the front wheels isn’t slightly higher, the transmission components will face opposing forces, causing tension and wear.

- Incorrect lead can result in rapid wear to the front tyres (if the ratio is too high, they pull excessively) or problems with heating of the hubs or abnormal clicking (if the ratio is too low, the rear pushes too much). This excessive strain may go as far as damaging the transmission and the pinions.

- Inversely, well-adjusted lead synchronises the wheels, optimising traction and reducing slip. This improves energy efficiency and decreases fuel consumption, while extending the lifespan of the tyres and leading to better driving comfort.

Impact of the dynamic rolling circumference on your lead

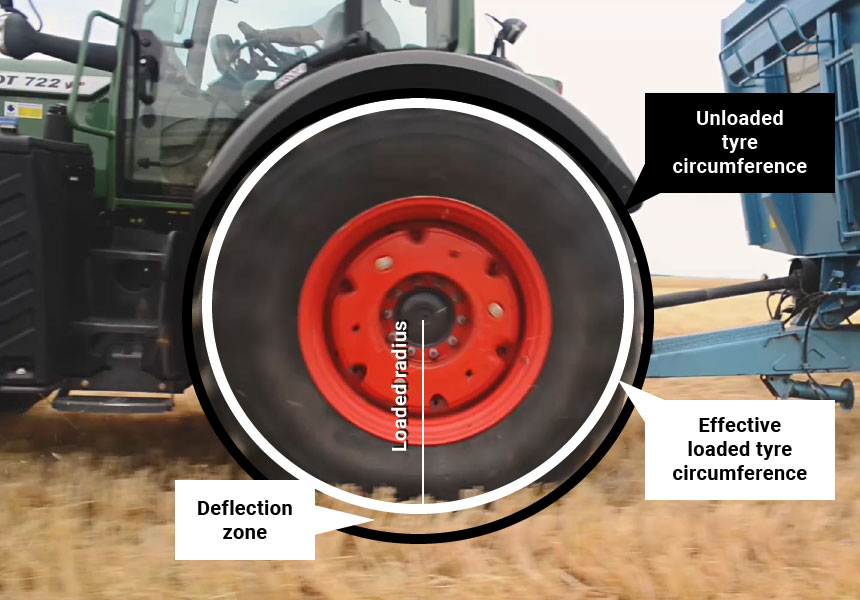

The rolling circumference is the exact measurement of the circumference of the tread of the tyre taking into account the thickness of the lugs with an average inflation pressure and no load.

A distinction must be made between this and the dynamic rolling circumference, which is the circumference of the tread when the tractor is at work and carrying a load. Unlike the static measurement of a new tyre, it takes account of the tyre’s change of shape when loaded, as well as torque and inflation pressure. This change of shape takes the form of a flat contact patch with the ground, reducing the effective radius and as such the actual circumference. This value is called dynamic because it fluctuates depending on the circumstances and the environment. It is nonetheless essential, because it has a direct impact on the calculation of the effective lead ratio of your tractor in the field.

Advice: To obtain a precise dynamic rolling circumference, you must adjust inflation pressure precisely to the tractor load, while taking account of travel speed. This type of data can be found in manufacturer user manuals.

2. What has an impact on the mechanical performance of agricultural tyres?

Are the generally accepted dimensions always valid?

There are combinations of standard dimensions such as:

Front tyres 420 / 85 R 28

Rear tyres 520 / 85 R 38

Or

Front tyres 480 / 70 R 28

Rear tyres 580 / 70 R 38

Or even

Front tyres 540 / 65 R 28

Rear tyres 650 / 65 R 38

While these are commonly used and often adequate, they do not always guarantee an optimal mechanical performance. These tyre combinations are likely to be suitable in 80 to 90% of cases.

Indeed, the actual rolling circumference may vary based on multiple factors and invalidate the initial lead ratio. Excess load or incorrect inflation pressure will distort the tyre, modifying its effective circumference and altering the lead ratio. These variations highlight the importance of considering lead as more than a simple set of theoretical dimensions.

If you replace all four tyres on your tractor

When the four tyres are replaced by tyre models that conform to manufacturer specifications, in particular in terms of dimension, and ideally brand and technology, the theoretical lead ratio is generally maintained. While load and pressure may influence the dynamic circumference of each tyre, the impact is proportional to the front and rear tyres, on condition that the load is balanced on the tractor and that the pressure settings are correct. So the lead ratio tends to remain stable within the acceptable range.

How do you detect a bad lead ratio?

Excessive slip, especially at the front, indicates a lack of adherence due to excessive traction. Inversely, slip at the rear combined with trouble steering may indicate too low a lead ratio, with the rear axle pushing too much compared to the front. This slippage reduces work efficiency, increases fuel consumption and wears the tyres prematurely.

Furthermore, if you hear a slight clicking noise when you brake, this is a sign of an incorrect lead ratio. It comes from the strain and too much play in the pinions, caused by a lead ratio that has strayed from the ideal 2.5%. Ignoring this noise can lead to rapid wear and costly damages to the transmission components.

3. What is the problem if you change only one pair of tyres?

A level of wear that is different between the front and rear

The lead ratio depends directly on the circumference of the front and rear tyres. Changing only one set of tyres creates a significant difference in circumference between the new ones (long lugs) and the old ones (worn lugs). This disparity alters the circumference ratio between axles, which can bring you out of the optimal lead ratio range (around 2.5%). Incorrect lead due to uneven wear causes poor synchronisation, slip, abnormal tyre wear and excessive strain on the transmission components.

Different brands of tyre between the front and rear

Using different tyre brands for the front and rear axles can compromise the lead ratio, even if the nominal dimensions are identical. The main reason lies in variations in the design of the casing (number of casing plies and/or number of stabilising and reinforcement plies) as well as in the different lug lengths depending on the manufacturer, which has a direct influence on the actual rolling circumference of the tyre. Fitting a different brand of tyre at the front and rear can create an imbalance in the circumference ratio expected by the manufacturer. This incorrect lead can cause slip, premature tyre wear and strain to the tractor’s mechanical transmission components.

Different tyre technologies

VF (Very High Flexion) tyres, designed to work at low pressure to minimise soil compaction, are more supple than standard tyres. This greater suppleness means that the tyres change shape more when loaded, which modifies their dynamic rolling resistance compared to a standard tyre of the same size. Combining different technologies on front and rear axles, even with identical nominal dimensions, creates an imbalance in the dynamic rolling circumferences in working conditions. This disparity disrupts optimal lead, causing slip, irregular tyre wear and a strain on the transmission components due to poor synchronisation of axle rotation speeds.

4. Which tyre should you choose to have the best mechanical performance?

To obtain the best mechanical performance from your agricultural tyres, Bridgestone’s VX-R TRACTOR tyre stands out thanks to its many advantages.

Bridgestone’s VX-R TRACTOR tyre for optimised lead

This high-tech tyre has been specially designed to guarantee perfect synchronisation between the front and rear axles of your tractor. By ensuring that the front wheels turn slightly faster than the rear wheels, with an optimal range of 1.5% to 3.5%, the VX-R TRACTOR tyre helps to protect the mechanical components of your tractor against strain and premature wear linked to poor synchronisation. This tight control over lead also results in better tractor handling and a longer lifespan for your tyres.

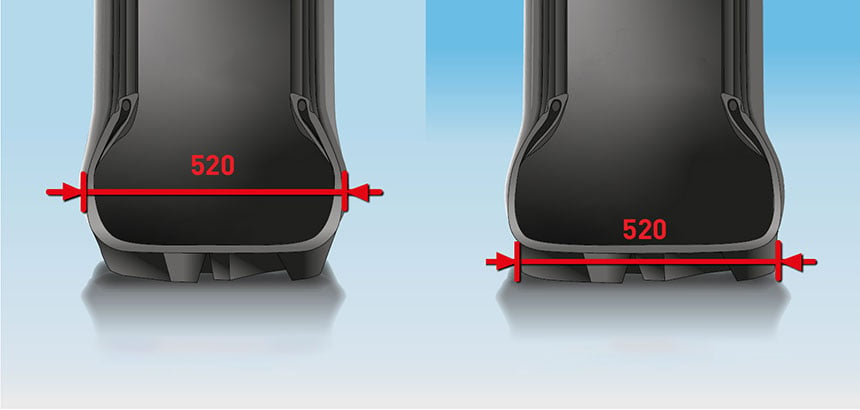

Identical marking and ground measurement

Another major strength of the VX-R TRACTOR tyre lies in its dimensional design. Unlike certain agricultural tyres whose width on the ground may be less than indicated, this premium tyre has a section width in contact with the ground that is perfectly identical to its nominal size. This wider tread maximises the contact patch with the ground, which improves traction considerably and results in better transmission of power to the ground.

Controlled front/rear lead = Mechanical performance of the tyre

By placing the emphasis on a controlled front/rear lead ratio, the VX-R TRACTOR tyre guarantees a better mechanical performance. Bridgestone has optimised the dimensions of each tyre in this range to operate in ideal front/rear combinations, whether between VX-R TRACTOR tyres or in combination with VX-TRACTOR tyres. By targeting a lead ratio of as close to 2.5% as possible, this tyre ensures better working efficiency, whatever the external conditions, better handling capacity and an optimised tyre wear life.

which has a drive ratio of 1.325

Front tyres VX-R: 480/70 R 28 - 140 D – Rolling circumference = 4254 mm

Rear tyres VX-R: 580/70 R 38 - 155 D – Rolling circumference = 5503 mm

We obtain an optimal lead ratio of 2.426

Optimisation of energy and engine performance

The VX-R TRACTOR tyre contributes towards energy optimisation and engine performance. As the front and rear axles are perfectly synchronised, the drive power is used to the full and fuel consumption therefore reduced, to produce better work. In addition, the wide tread and the innovative ‘Involute’ lug design encourage good adherence to the ground, which limits slip and energy loss. This reduction in slip also leads to less fuel required, thus improving the overall efficiency of your tractor.

CONCLUSION

Optimal mechanical performance in agricultural tyres, based on a carefully managed lead ratio, preserves the efficiency and longevity of your tractor. It guarantees a better synchronisation of the wheels, maximising traction and minimising slip, which leads to better energy efficiency and a reduction in fuel consumption.

Maintaining a good lead ratio protects the mechanical components of your machine against premature wear and extends the lifespan of your tyres, contributing to greater productivity and lower operating costs.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc.

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles:

- 5 essential techniques to optimise your agricultural tyres

- How can you manage the rolling resistance in agricultural tyres better?

- What are agricultural tyres’ high-strain zones?

- Should you change the rim for wide agricultural tyres?

- Is a premium rim better suited to my tractor tyres?

- What is the link between the environmental impact of tyres and your profitability

- Braking capacity: role and impact of the agricultural tyre

- Are adjustable rims better than welded rims?

- How reliable are your agricultural tyres when cornering?

- How do you ensure that your tractor tyres have a good self-cleaning capacity?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *