Your first thought is certainly that the tread is the main high-strain zone on your agricultural tyres because it is in direct contact with the ground, but this is not necessarily the case.

In reality, the tread is certainly placed under a great deal of strain: traction, torque, wear, rubbing, heating, and must also be cut-resistant depending on the type of soil… but it’s also the most resistant part of the tyre, which has a rubber compound specifically developed to cope with these factors.Unlike car tyres, agricultural tyres have to be used for multiple tasks, on the roads and on soft, wet soil in the fields as well as in the farm courtyard for handling operations, which modifies the zones of stress and strain that can distort tyres.

In this article we look at the principle high-strain zones specific to agricultural tyres and what you must do if you wish to reduce the specific stress in these areas, to keep your tyres for longer.

1. First high-strain zone: the shoulder

An important zone that is often underestimated

The shoulder is the contact zone between the tread and the sidewalls. It’s the zone situated at the end of each agricultural tyre lug. This specific part of the tyre is an intensive flexion zone, placed under the strain of an excess load or too much torque.

It is very important because it allows the overall structural integrity of the tyre to be maintained and ensures the cohesion between the principal parts of the tyre. The shoulder is multifunctional, and plays a role in shock absorption, road handling and transmission of tractive force.

When the tractor is overloaded, the shoulder faces strain that can lead to major distortions, potentially leading to a break in the structure if the tyre is not sufficiently high-tech or is not used correctly.

The shoulder is often the first contact area during impacts or accidents.

It is not an area where the damage is easily visible. The strain is felt principally at the level of the internal structure, at the heart of the tyre casing.

A visual check-up is not enough to assess the state of the shoulder. Resistance in this zone depends on the quality of the layers of fabric and rubber reinforcement used in the construction of the casing.

How to reduce strain to the tyre shoulder

To protect the shoulder of your tyres, you must check the load carried by your tyres and adjust pressure settings accordingly to cope with this load. These pressure settings must obviously take into account travel speed on each type of ground: exclusively in the fields, exclusively on the road or mixed road and field use.

Suitable pressure makes it possible to spread the weight more evenly over the tread as a whole, thus reducing the stress to the shoulder. A correctly inflated tyre copes better with impacts and heavy loads, thus increasing its longevity and improving its performance capacity.

2. Second high-strain zone: the bead

The bead is a critical zone which requires special attention. It’s the second zone on an agricultural tyre that faces a high level of strain.

It connects the tyre and the seat of the rim. It has to ensure airtightness and cohesion between very different materials. It must be relied upon for the transmission of torque between the rim and the tyre.

The tyre’s casing plies run behind the bead (on the inside) and in front of the bead (on the outside) making this zone particularly fragile and sensitive to movements as well as repeated flexion and deflexion.

This fragility is explained by the complex internal structure of the bead. Although it contains metal plies, the bead is vulnerable to mechanical strain and external shocks.

If impurities such as earth, stones or branches slip between the bead and the edge of the rim, they can cause significant damage.

Furthermore, a rim in poor condition, misshapen, rusty or worn can accelerate wear to the bead.

How to reduce strain at the level of the bead

Here is our advice to help you protect your agricultural tyre beads:

- Clean the rims regularly: the cleaner they are, without debris, the less the risk of corrosion and premature wear at the level of the bead will be,

- Monitor tyre pressure: a regular check-up will ensure that the bead can bear the load correctly without becoming excessively misshapen. Pressure that is too low with standard tyres not designed to work at low pressure can result in the tyre breaking at the level of the connection with the rim.

3. Third high-strain zone: the tread

A reinforced high-strain zone

The tread is the most visible surface of the tyre and the most highly solicited. It’s the most obvious high-strain zone, which is exposed to all the hazards of the ground. It’s at this level that the most direct contacts with the ground occur and where all the strain is concentrated.

The tread is resistant because it comprises overlapping layers of fabric cross-plies as well as rubber (also known as the ‘’belt’’), and is responsible for traction, adherence and wear-resistance.

The stabilising plies present in the tread play a crucial role. They ensure a good control of steering, contribute towards stabilising the tyre on the ground by spreading the pressure exerted by the load evenly. This ensures better adherence, good road handling capacities and even wear to the tread.

Protecting the tread will make your tyres last longer

To protect the tread of your agricultural tyres efficiently, it is essential to take into consideration the use for which your tyres were designed when using them.

- Avoid overloading them: by complying with the load capacity recommended by the manufacturer, you will protect the structural integrity of your tyres and reduce the risk of rapid wear to the tread.

- Adapt pressure and maintain an inflation pressure that is suitable for the type of work, the load and the terrain. This ensures an even distribution of weight over the contact patch with the ground, which improves traction, reduces wear to the tread and leads to better adherence.

- Inspect the tyres regularly: checking the state of your tyres allows you to detect any abnormal wear, damage or sign of deterioration. This will allow you to make the necessary adjustments and avoid the premature replacement of your tyres.

4. Fourth high-strain zone: the sidewalls

The sidewalls are the tyres’ lateral walls. They are part of an essential flexion area. They do not just maintain the tread in place, they also have an absorption function, absorbing shocks, torque and strain during agricultural labours.

This zone which is made of more supple rubber is more vulnerable to damage, especially when it comes in direct contact with the ground, making it sensitive to cuts, tears and perforation.

You therefore need to take special precautions when you work at low pressure with standard tyres that are not suitable for this type of use.

The sidewalls are placed under considerable strain due to the torque generated by the power of the tractor during different agricultural activities.

This strain can lead to breaks in the internal structure of the tyre. Excess load or incorrect pressure settings can result in the sidewalls being overloaded, which increases the risk of damages and premature wear.

To ensure that the sidewalls remain intact and guarantee driver safety, you must follow the pressure recommendations given by your tyre manufacturer. This reduces the risk of accidents, leads to better road handling capacities and better responsiveness during complex manoeuvres.

5. The VX-TRACTOR tyre is more resistant at the level of the usual high-strain zones in agricultural tyres

Bridgestone’s VX-TRACTOR tyre is a technical innovation in the agricultural tyre sector. It is designed to meet the specific needs of the most exigent farmers, with its high-tech features and a very robust design.

of the usual high-strain zones in agricultural tyres

Increased longevity and wear life

This high-tech tyre stands out for its remarkable resistance at the level of the usual high-strain zones.

Its innovative design and a rubber volume that is far greater than that of its competitors gives it exceptional durability, thus meeting farmer demands in terms of tyre longevity.

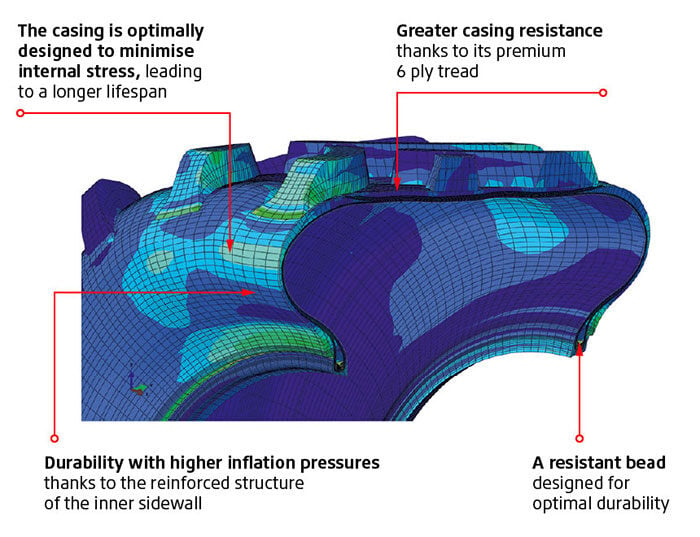

A more robust casing

Thanks to its reinforced casing, the VX-TRACTOR tyre can carry heavy loads without compromising performance.

It is built with an additional casing ply and two additional stabilising plies compared to standard tyres.

This robustness allows it to cope with extreme conditions in the most demanding environments.

Great resistance to wear

Specially engineered by Bridgestone, this premium tyre offers greater wear resistance thanks to its rubber compound, mixed with plant-based oil.

It has a volume of rubber of up to 20% more at the level of the lugs compared to its competitors. These options make it one of the most wear-resistant tyres.

A more efficient tread

The design of the VX-TRACTOR tyre tread contributes to its exceptional traction capacity. Thanks to its exclusive and patented “Involute” lug design, this tyre offers outstanding traction while minimising the negative impact to the ground.

Agricultural tyres are placed under considerable strain, in particular at the level of the shoulder, the bead, the tread and the sidewalls.

To keep your equipment intact and ensure your safety, the first thing to do is to follow the manufacturer recommendations in terms of load and pressure. A regular check-up is also advisable to detect any abnormal wear or damages, and will allow you to take the measures necessary to ensure that your tyres last and continue to perform.

In addition to its supple yet robust casing, Bridgestone’s VX-TRACTOR tyre stands apart due to the innovative design of its tread, which is capable of resisting the usual strain faced by agricultural tyres.

It has a better performance capacity in all working conditions, whether out in the fields or on the road. Investing in this premium tyre ensures that you obtain a constant performance level and good productivity, at the same time as exceptional durability.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc.

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles:

- 5 essential techniques to optimise your agricultural tyres

- Agricultural tyres: rules for managing the lead ratio

- Managing the load transfer to the front tyres in polycropping

- What are the signs of an incorrect lead ratio?

- Impact of the dynamic rolling circumference of agricultural tyres

- What is the impact of the section width of your agricultural tyres

- Do my tractor tyres have a wide enough footprint?

- Can my agricultural tyres help reduce my fuel consumption?

- Does improper lead invalidate your agricultural tyre warranty?

- How can you manage the rolling resistance in agricultural tyres better?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *