You have noticed abnormal wear to your agricultural tyres, or your tractor’s manoeuvrability doesn’t seem normal when you are working: too much slip, the rear axle pushing too much or the front axle that isn’t catching enough… it is quite possible that you are seeing the effects of an unsuitable lead ratio.

The lead ratio is often considered as just a mechanical piece of data despite the fact that everything that concerns your tyres may have an impact on your lead ratio and generate numerous inconveniences which at the least slow down your work and at the worst lead to the premature replacement of your tyres, or the transmission breaking.

To avoid this kind of problem, here are the rules and the factors to take into account for a better understanding and control of your lead ratio:

1. The lead ratio: what is it?

On a 4WD tractor with unequal wheels, the rear wheels are larger than the front wheels, so the rotation speed is not the same.

To have a good synchronisation of the front and rear axles and to obtain optimal traction, the front axle must advance slightly faster than the rear axle. This leads to a “pulling” effect when front wheel drive is engaged. It is this difference, expressed as a percentage, that we call the “lead ratio”.

An appropriate lead ratio is required to ensure that the different mechanical components of the tractor function correctly, such as the engine, differentials and transmission…

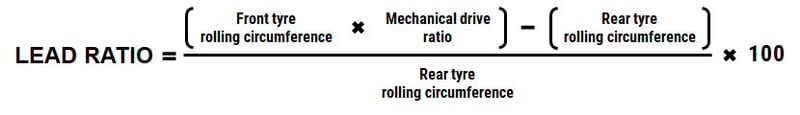

To calculate your tractor’s lead ratio, you need to know:

- The drive ratio, information supplied by the tractor manufacturer, calculated to obtain perfect synchronisation of the drive shafts

- As well as the exact rolling circumference of your front and rear tyres in mm.

Once you have that information, apply the following formula:

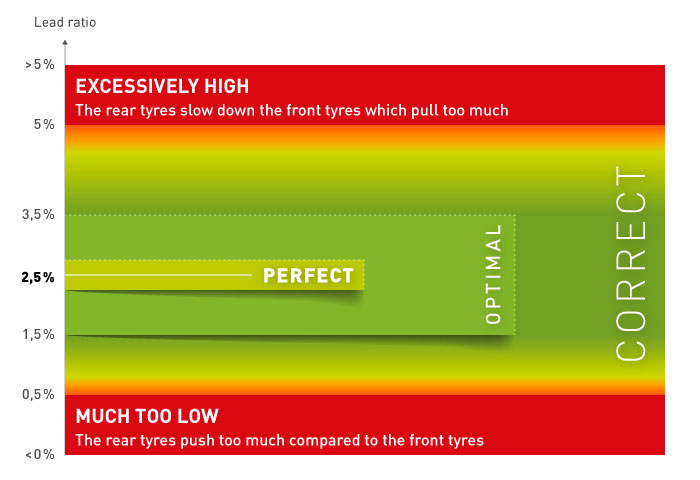

What is the right lead ratio

The result of the formula is expressed as a percentage and should be close to 2.5% to be optimal.

- If the lead ratio is above 5% it is excessively high, in this case the rear tyres slow down the front tyres which pull too much.

- If it is between 0.5 and 5% it is correct and within the accepted norm, it is optimal at between 1.5% and 3.5% and perfect at 2.5%.

- If it is between 0.5% and below 0, it is much too low (lag), in which case the rear tyres push too hard compared to the front tyres.

The tyres’ rolling circumference has an impact on the lead ratio

The above formula shows us that the calculation of the lead ratio is closely linked to your tyres’ rolling circumference. This may change with wear, for example, which will have an impact on the lead ratio and could have a negative effect on the tractor’s efficiency by causing operating anomalies.

An incorrect lead ratio can lead to an increase in slippage or abnormal wear to your tractor tyres. Other unusual signs should also draw your attention:

- Premature wear to the front set of tyres compared to the rear tyres.

- A rear axle that has a tendency to slip excessively.

- Steering that is not very responsive on heavy soil.

- An abnormal clicking when the 4wd is engaged.

- A sharp snapping sound when braking on the road.

If you come across these different signs, don’t hesitate to check your effective lead ratio by using the formula above.

2. Tyres with the same dimensions may have a different circumference depending on the brand

If you wish to change the tyres were originally fitted, you must pay close attention to the lead ratio when you choose new tyres because two models with the same dimensions indicated on the sidewalls will not necessarily have the same circumference, depending on the tyre brand.

Bear in mind that the dimension of an agricultural tyre corresponds to the markings on the sidewall. These technical data are standardised measurements which comply with European norms. However, they do not take all the tyres’ exact dimensions into account.

The rolling circumference is not standardised, because it is variable

The rolling circumference is not marked on the tyre’s sidewall. This is the distance covered by the tyre in one complete rotation (one turn) but it can be defined as the measurement in mm of the length of the tyre’s tread. This is a very important indicator for the calculation of the lead ratio.

These dimensions may be very different depending on the tyre brand, because the lugs are not necessarily the same height. Often we change one set of tyres only at the front or at the rear and this may cause a problem when you fit a different brand on one of the two axles. Simply by changing brand, you may end up with an incorrect lead ratio between the front and rear axles.

The technology and type of use have an impact on the lead ratio

If you opt for tyres with the same dimensions, but that were made using different technologies, you will encounter the same problem. Not every technology offers the same deflexion capacity, given that the casing of a tyre made using VF technology can operate at a pressure as low as 0.6 bar, whereas a standard agricultural tyre should remain at around 1 bar.

The theoretical lead ratio based on the dimension marked on the sidewall does not correspond to the exact rolling circumference. The manufacturer simply gives a tolerance bracket for the lead ratio. This ratio then evolves in line with the life of the tyre, depending on the use of the tractor and its tyres.

A discrepancy of between 0.5% and 1% in the lead ratio can lead to the desynchronisation of the front and rear axles of the tractor.

3. What is the impact of wear on the lead ratio?

Over time, the height of the lugs may diminish by several centimetres. Wear to the lugs will have a major impact on the rolling circumference, which is likely to modify your tractor’s lead ratio. For example, when you change only the front tyres, the rear tyres are more worn and the rolling circumference is different from that of the new tyre which is used for your theoretical calculation.

The lead ratio settings are more or less the same as long as your front tyres wear at the same rate as your rear tyres. When you want to change the front set of tyres or rear set of tyres, make sure you measure the actual rolling circumference of your tyres (including wear).

The idea is to obtain the right lead ratio settings in order to improve your tractor’s traction, which should in turn improve your yields.

4. Why do load and inflation pressure have an impact on the lead ratio?

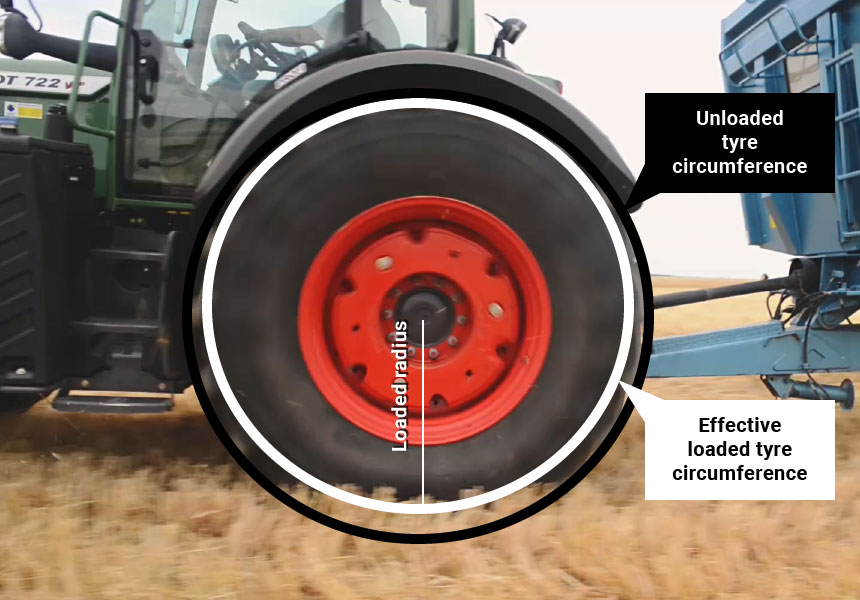

The brand, the technology and tyre wear are not the only factors that can have an impact on the tyre’s unloaded circumference. The rolling circumference or length of the tread on the ground also change depending on the load carried or the inflation pressure.

When you carry heavy loads or you work at a very low inflation pressure to preserve the soil on your land, the effective circumference of your tyres will not be the same. The tyres will flatten out on the ground, thus reducing the radius between the centre of the axle and the ground (loaded radius).

In this case, you obtain a new effective tyre circumference which can have a significant impact on your tractor’s lead ratio.

The lead ratio is still correct if it remains within the 0.5% to 5% bracket. As long as your adjustments and measurements allow you to stay within this tolerance, you can consider that the front and rear axles are still synchronised.

As the unloaded circumference is different from the effective loaded circumference, the latter is more importance given that the load or pressure crushes the tyre, thus reducing its real circumference.

Conclusion

If you set yourself the objective of having a lead ratio as close to 2.5% as possible, this will make a real difference to the quality of your work. Your front and rear axles will be perfectly synchronised, because your 4 wheels will act together. A good lead ratio setting will give you optimal traction, reducing slip and the amount of fuel used.

As we have seen, many factors have an impact on the lead ratio (wear, pressure, load…), so by being as close to 2.5% as possible when you fit your new set of tyres, you are certain to stay within the right tolerance range, irrespective of variations linked to external factors.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc.

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles:

- 5 essential techniques to optimise your agricultural tyres

- Which vibrations are directly linked to agricultural tyres?

- Load comparison between standard agricultural tyres and VF tyres

- Impact of the loaded radius for my agricultural tyres

- VF agricultural tyres versus caterpillars: Pros and cons

- Why should you check your harvesting tyres before the start of the harvest?

- Which agricultural tyre makes it possible to avoid coming off the rim at low pressure?

- What is the impact of implement settings on tractor tyres?

- Fleet audit: what is the main benefit of agricultural tyres?

- Do you really use the full capacity of your VF agricultural tyres?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *