If you notice unusual tractor tyre wear, this may be an indication of a problem with your implement settings. After having checked air pressure and tractor tyre alignment, if everything seems in order, the problem may be linked to your tooling, so you should check your implement settings in relation to your tractor.

To avoid this type of problem, you must always respect the overall coherence between the power of the tractor and the size of the implements: an implement that is too big is not suitable for a low power tractor, even with wide or voluminous tyres.

The type of plough you use must be suited to the soil on your land and be in good condition, because if it is too worn, it will counteract the tractor’s tractive force.

Here are the 3 main cases of implement settings which can have an impact on your tractor:

1. Incorrect alignment of implements that the tractor tyres will compensate for

The right alignment between tractor and implement is important to protect your tyres against rapid wear. If the implement is misaligned, force will be transferred laterally to the tractor frame and this force will be passed on to the tyres, which will compensate thanks to their suppleness.

Check the alignment of the plough during tilling

During tilling, your plough must be perfectly aligned with the centerline of the tractor to follow the furrow in a straight line and make the most of the tractive power. Tractive force is transmitted to the ground by the tyres and if there is any misalignment between the implement and the tractor the tyres will not be able to operate optimally.

Whatever plough model you use, there are many settings that can be adjusted:

- Depth of tilling.

- The pitch adjustment so that all the ploughshares work at the same height and the plough is parallel to the ground.

- The vertical setting so that the plough is perpendicular to the ground.

- Offset and angle control settings: offset for the width of the first ploughshare and angle control for the axis of the plough with respect to the tractor.

It’s this last setting, angle control, which must be very precise because if the plough’s centreline is not set correctly, this will generate lateral tension at the level of the coupling system and imbalance the back of your tractor towards the right or left.

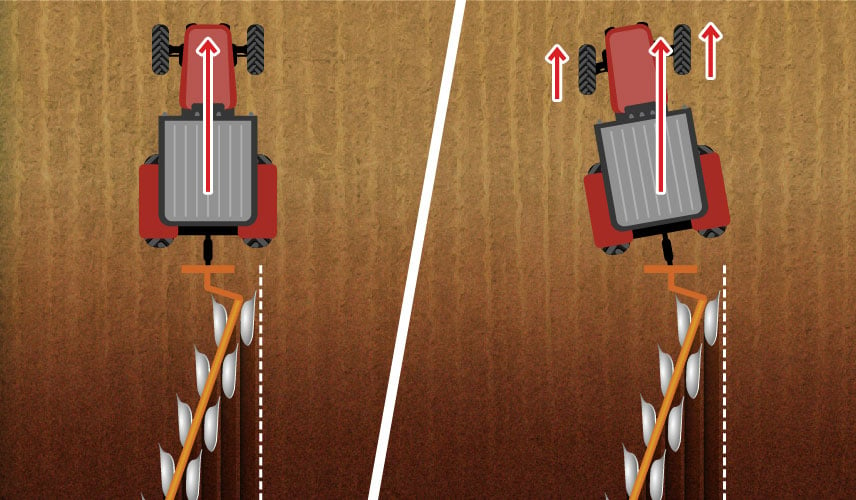

On the right incorrect implement settings lead

On the right incorrect implement settings lead

to the tractor veering off course

which has to be permanently corrected by the steering

Incorrect angle control settings on the plough will cause wear to the central part of the lugs on the rear tyres, which are not perfectly in line with the tractor’s travelling direction.

Traction is slightly off-centre, which you may realise if you have to constantly correct the steering to stay in line with the furrow. The rear axle will slip permanently and when the slip rate exceeds 15%, you will increase fuel consumption in addition to wearing out your tyres.

Check the alignment of the trailer axles with the tractor

The problem is the same for trailers as it is for ploughs, and all the elements of the combination vehicle must be perfectly in line.

There is less rolling resistance on the road than when tilling, but the speed and the abrasiveness of the asphalt increase the extent of scraping on the ground, if all the axles are not in line. You must check parallelism regularly as well as the alignment of the axles of your trailers with the tractor axles, because geometry errors can be a cause of rapid wear to the rubber of your tractor tyres.

There are numerous signs which should draw your attention:

- You notice abnormal wear to the lugs of the rear tractor tyres: rear right tyres with wear to the outside of the lugs, rear left tyres with wear to the inside of the lugs.

- Your tractor veers to the left or to the right.

- You have to adjust the steering when driving in a straight line because your tractor pulls to one side or the other.

Rear left tyre - Rear right tyre

Rear left tyre - Rear right tyre

Wear to the lugs only on the rear tyres

2. Deep tilling has an impact on tyres

Tyres are essential for transmitting the engine power you need for traction to the ground, but each element that slows down the tractor must be adapted or adjusted to limit rolling resistance. The following points are worth noting:

Wear to the plough

All working parts must be in good condition and not show signs of wear. The leading edges of the ploughshares must be sharp, the mould boards must be in good condition (smooth, with no rough edges) and the discs must be sharp for disc ploughs.

Irrespective of the type of ground, when a plough is in good working order, this will limit resistance to traction and protect your tyres against overly rapid wear.

Impact of the depth of tilling on tyre wear

The deeper you till, the more tractive force has to be transmitted to the ground by your tyres. Before starting operations, you must define the tilling depth at which you wish to work, based on the type of land, the quantity of vegetal waste and the depth at which you wish to bury these vegetal residues. You may also take into account the fuel consumption required for your tractive force and the impact of your tilling on tyre wear.

The deeper you work, the further the tool digs down and the more rolling resistance increases and slows down your tractor.

- Adjusting plough settings to work at a depth of 10 cm leads to only 2% to 8% slip: this very low slip ratio limits tyre wear as well as fuel consumption.

- Adjusting plough settings to work at a depth of 20 cm leads to 12 % to 18% slip (or more depending on the moisture content) which is around 6 times more slip for just twice the depth. Beyond this slip ratio, you will have to adapt your engine speed, reduce travel speed or raise your implement slightly.

If you increase your tilling depth to more than 20cm, the slip rate will be even higher, tyre wear will accelerate and you will need more time to plough your field.

You must think carefully before deciding on a tilling depth because it has a major economic impact. In addition, shallow ploughing gives you the advantage of keeping organic material in the upper layers of the soil.

Pressure settings and tyre quality

It is essential to adapt tyre pressure settings before adjusting plough settings, as incorrect inflation pressure is counterproductive. If your tyres are overinflated, the tractor will effectively tend to sink deeper and compact the soft earth which has just been tilled. Your objective should be to maintain pressure as low as possible so that the tyre morphs into the contours of the earth rather than crushing it.

In order to work at low pressure, you must take into account the weight of the implement and your tyre technology.

Among the most tried and tested high-tech models, VF VT TRACTOR tyres are particularly well suited to tilling.

- These sophisticated tyres have been designed to preserve your soil.

- They have a reinforced casing and supple sidewalls which make it possible to work at very low pressure, given that you can reduce pressure to as little as 0.6 bar.

- They provide a very large soil footprint with a lug contact patch which is up to 26% bigger than standard tyres, which mechanically increases the traction capacity.

- The difference in productivity is enormous, not to mention the fuel savings linked to the reduced slip you will benefit from all day long.

3. The load transfer from the implements to the tractor has an impact on the tyres

If you draw heavy implements, or those which require high torque, you must ensure that your tractor can produce the tractive effort necessary to pull your combination vehicle and that your tyres are able to pass on this tractive force.

If the rear axle of the tractor alone bears the load transfer from the implement, traction will not be optimal because the front axle only contributes slightly towards the tractive effort. The excess strain on the rear axle will lead to more slip and speed up the tyre wear process.

To reduce the negative impact of the load on the tyres, you have to compensate for the load transfer to the rear by adding mass to the front lift to obtain a spread of 40% to the front and 60% to the rear of the tractor.

VT-TRACTOR tyres with a load capacity of up to 40% more

VT-TRACTOR tyres with a load capacity of up to 40% more

Using VF tyres such as the VT TRACTOR tyre allows you to draw heavy implements and to carry more weight. These high-tech tyres have a more resistant casing made with specific materials which increase their load capacity by up to 40%.

A plough is an implement which requires high torque, the load transfer increases on the rear axle during traction in the fields. This changes the balance of the loads calculated beforehand while the vehicle is stationary.

This load transfer is taken into account by slightly increasing front ballasting while the tractor is stationary to compensate for the load during tilling.

As we have just seen, implements can have a major impact on tyre wear and in the case of wrong settings, often only minor in appearance, this will lead to premature replacement of your tyres.

The small adjustments to be made are not much to ask for on a daily basis (pressure, alignment, load control) but can have significant consequences on your tyres’ lifespan.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc.

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles:

- 5 essential techniques to optimise your agricultural tyres

- How do you ensure that your tractor tyres have a good self-cleaning capacity?

- Agricultural tyre evolution, what impact on my farm?

- Agricultural contractors: improving quality of service with an adapted agricultural tyre

- Which vibrations are directly linked to agricultural tyres?

- Load comparison between standard agricultural tyres and VF tyres

- Impact of the loaded radius for my agricultural tyres

- VF agricultural tyres versus caterpillars: Pros and cons

- Why should you check your harvesting tyres before the start of the harvest?

- Which agricultural tyre makes it possible to avoid coming off the rim at low pressure?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *