Preserving your soil by avoiding excess compaction is a good strategy to secure future yields. To prevent compaction you know that you should work at low pressure, and having referred to the manufacturer recommendations you see that you can reduce the inflation pressure in your standard tyres.

However, working at low pressure means that there are more rules to follow so that you do not transform this golden opportunity to preserve your soil into a machine breakdown, potentially involving the replacement of set of tyres with additional costs that will cancel out all your efforts.

Working at low pressure effectively exposes you to a more frequent risk of the tyre coming off the rim, although there are ways of avoiding this type of incident. Here are the rules and good habits to adopt so that your tyre never comes off the rim when you are driving an agricultural vehicle:

When working in the fields, reducing pressure is a good way to preserve your soil, but insufficient inflation pressure is one of the most frequent causes of the tyre coming off the rim, which is generally linked to other factors, such as excess load transfer, very steep land or inappropriate driving on the road or in the fields.

Here are the most frequent cases of the tyre coming off the rim:

1. Coming off the rim due to speed when cornering

Whether it’s standard or a top of the range model, each tyre has a speed index which must be respected if you wish to use your agricultural tyre for longer. This is a limit that you must not exceed if you wish to avoid damaging your tyre prematurely, especially if you are driving with underinflated tyres:

- In the fields, you must control speed and never exceed 15km/hour to avoid this type of inconvenience. If you accelerate more at the end of the row when the implement is no longer engaged, the risk of coming off the rim increases when you turn the corner, because the load transfer to the tyres opposite the bend will be very high. It is therefore highly advisable to reduce speed, especially when cornering at the end of the row.

- On the road, underinflated agricultural tyres tend to deform more easily, especially as speed is accompanied by a sharp rise in temperature, which modifies the reaction of the rubber compound used in the tread. With a low inflation pressure and at speed in the bend, the tyre is certain to warp. The bead will lift off from the edge of the rim, leading to a sudden loss or pressure and the tyre coming off the rim.

A tyre coming off the rim as a result of speed and load

A tyre coming off the rim as a result of speed and load

When your tyre comes off the rim, this obviously means that it has to be replaced immediately and that you will lose time on operations due to the need for breakdown services to intervene. The most efficient solution for your wallet is therefore to limit speed when you drive at low pressure with tyres that were not designed for this type of pressure setting, especially if your tractor is loaded, and above all when driving around bends and cornering.

2. Coming off the rim as a result of sloping land

When you work at a low inflation pressure, a tyre can also come off the rim as a result of a high load transfer that is not offset by the trailing tyres when working on a slope. If your fields are on hilly land, you must take the precautions necessary to avoid this type of accident.

When your tractor is facing down the slope, the total weight of the trailer will crush the front axle of the machine and inversely, the front axle will be totally weightless when the tractor goes uphill, with the rear tyres bearing the full weight of the combination vehicle. The risk of the tyre coming off the rim increases when you work laterally along the slope, because the load transfer to the lower side of the trailer increases in proportion with the gradient.

The steeper the slope you work on, the more the strain becomes excessive on your tyres. If you haven’t set the inflation pressure meticulously or if you have neglected to take load transfer into account, you run the risk of the tyres coming off the rim as soon as the load on the lower tyres is above the load index and pressure reference recommended by the manufacturer.

When a tyre comes off the rim, your operations will be interrupted for some time, especially given that repairs are more complex and time consuming on hilly land.

A tyre coming off the rim as a result of the slope and load

A tyre coming off the rim as a result of the slope and load

3. Coming off the rim linked to bad management of low pressure

The speed and slope of the land are not the only factors to take into consideration if you wish to avoid damaging your agricultural tyres. If you choose to work at low pressure, you must be capable of managing this type of pressure setting accurately and not going below manufacturer recommendations at the risk of coming off the rim rapidly.

When the working areas to be covered involve steep slopes or inclines, don’t hesitate to increase pressure by 0.4 bar for tractors, or even 0.5 bar for harvesting machinery. For standard tyres, it’s always better to remain within minimum pressure of above 1 bar, because these tyres are not designed to work continuously at low pressure.

How to manage low pressure with standard tyres?

It is true that certain pressure charts supplied by your tyre manufacturers give a very low minimum pressure, which may start at 0.6 bar for a given speed and load. It is effectively possible to drive at 0.6 bar with standard tyres that were not designed for this level of pressure, but this must be exceptional, and reserved for the most extreme situations, such as when you are working on an area of land that is particularly difficult: very loose, wet soil.

With this in mind, you must respect certain conditions meticulously to avoid coming off the rim and to preserve your tyres at this level of inflation pressure. Above all, you must know the exact weight of the tractor, the implement and the load transfer. With this information you can establish the feasibility of the very low pressure option. You must then respect the following 4 points:

- Drive short distances only.

- Reduce speed as far as possible (10 km/h).

- Work in straight lines.

- Stay on flat surfaces.

4. How to reduce the risk of coming off the rim?

It is perfectly possible to avoid the risk of coming off the rim by adopting a few good practices such as complying with manufacturer indications, controlling speed, or using tyres whose technology corresponds to this type of use, such as VF tyres.

Follow manufacturer recommendations for the 3 related points: load/pressure/speed

When you drive with underinflated tyres in the fields or on the road, the golden rule to ensure that your agricultural tyres last longer is to follow the manufacturer’s recommendations for the 3 related aspects that are load, pressure and speed:

- Load: each agricultural tyre has its own characteristics, which include its load index. This indicates the maximum load that your tyre can carry with the appropriate pressure, only if you stick within a certain speed limit. If you transport more than the recommended load with underinflated tyres, with the aim of avoiding soil compaction, your tyres may potentially come off the rims or run into other problems at any time.

- Pressure: this varies based on the load and the maximum rated speed. For standard tyres that are not designed for work at low pressure, it’s best not to go below 1 to 1.2 bar. If you wish to reduce pressure to 0.6 bar, it’s always best to choose tyres that have been specially designed for this purpose, such as VF (Very Improved flexion) tyres.

- Speed: this is indicated by the speed rating that you will find on the sidewall of your tyre next to the load index. This is the maximum speed for the tyre when loaded. Warning: if the load increases, the speed must be reduced proportionally. Today’s tractors are increasingly powerful and fast. The more powerful they are, the more we tend to accelerate, which raises the risk of pushing beyond the tyres’ capacity without realising. Yet driving at speed with a low inflation pressure is really not wise. When your tractor is loaded, the best precaution you can take is to reduce speed and always follow manufacturer recommendations.

Use the right agricultural tyre technology to avoid the problem

If you wish to work at low pressure for soil preservation purposes, the best option is certainly to choose more high-tech tyres, such as VF tyres which were designed for work at low pressure. Their multi-layer design and reinforced casing provide a greater flexion capacity. Their sidewalls are more supple and more resistant than standard agricultural tyres.

One of the greatest advantages of a VF tyre is that it has a structure which increases resistance to load. It can carry an additional load of up to 40% more than a standard tyre, at the same speed but with a lower inflation pressure.

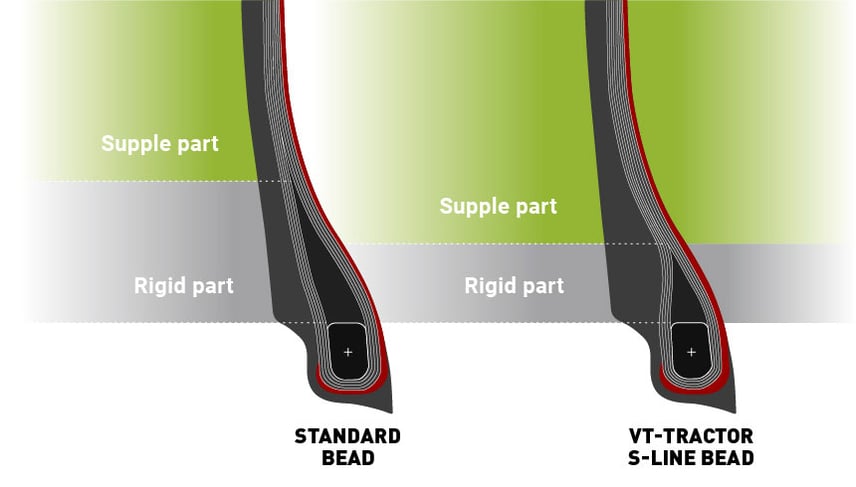

The more supple S-Line bead profile prevents the tyre from coming off the rim

The more supple S-Line bead profile prevents the tyre from coming off the rim

A tyre bead adapted to low pressure

A tyre comes off the rim when there is a loss of pressure linked to the bead becoming unseated. This happens more frequently with standard tyres which have a more rigid design. If there is too much flexion, the tyre comes out of the rim seat due to the leverage effect.

The VF VT TRACTOR tyre bead, on the other hand, is designed to work at low pressure and has a highly specific rubber compound and thicker rubber which allows for greater flexion. The S-line bead profile technology secures the connection between the rim and the tyre at lower pressure, offering better dynamic properties.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc.

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles:

- 5 essential techniques to optimise your agricultural tyres

- What is the maximum load that your tractor tyres can carry?

- How do you ensure that your tractor tyres have a good self-cleaning capacity?

- Agricultural tyre evolution, what impact on my farm?

- Agricultural contractors: improving quality of service with an adapted agricultural tyre

- Which vibrations are directly linked to agricultural tyres?

- Load comparison between standard agricultural tyres and VF tyres

- Impact of the loaded radius for my agricultural tyres

- VF agricultural tyres versus caterpillars: Pros and cons

- Why should you check your harvesting tyres before the start of the harvest?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *