Performing an audit of your fleet assets is a good opportunity to review the compatibility of your agricultural machines with all your available implements.

We often associate a tractor and the implement purchased at the same time with a specific work objective. But it may be astute to reconsider whether your equipment is really a good match and make the choice to adapt certain combinations, by making use of a little used parameter: a change in tyre technology. This can allow you to increase the load or improve resistance which offers new possibilities of getting more from your machines, by optimising the efficiency of your fleet just by a change of tyres.

Each farmer, each farm, each agricultural contractor works with several machines and many implements. An audit of the fleet assets must make it possible to optimise the use of these implements with the machines available depending on the type of crops and different farm criteria.

Thanks to this Audit, you can establish the hourly cost of your equipment and implements as well as the operating cost of each of them depending on the extent of its use, with the objective of using the full capacity of your equipment. The importance of the role of tyres comes to the fore when you know that depending on the technology used you can increase the capacity of certain implements or machines.

There are many advantages brought by a fleet audit:

- Having an overall view of your fleet assets and a situational analysis of all your machines and implements.

- Facilitating decision making: the inspection helps you identify weak areas and make the necessary improvements.

- Analysing the real cost of use: you can calculate your various expenses, in particular tyre related costs, by analysing the level of wear and the frequency at which you replace your agricultural tyres.

- Analysing tyre compliance: the audit enables you to check the tyres used on your farm and ensure that they are fit for their purpose to avoid damages or accidents.

Here, in 3 points, is how to take advantage of a fleet audit to improve machine performance just by using the tyres.

1. Do your current tyres correspond to the implement load?

Your tractor’s original tyre is not necessarily the most efficient for the specificity of your farm. Your current tyres may no longer be suitable for the actual load that your implements have to carry.

You can of course compensate by increasing inflation pressure, but this will lead to more rolling resistance and slippage, thus more rapid wear to your tyres, resulting in their premature replacement, which is not the most economic option.

Change tyre size to work with a greater load capacity

The fleet audit will establish which machine is equipped with tyres that are the wrong size for your implements. This doesn’t stop you working, but without realising it, rolling resistance, slip, soil compaction and fuel consumption all increase. These combined negative factors represent a considerable expense at the end of the year of which you were not aware.

A detailed analysis will determine which machine could become more polyvalent, working with heavier implements, increase its capacities, just by changing tyre size, for example.

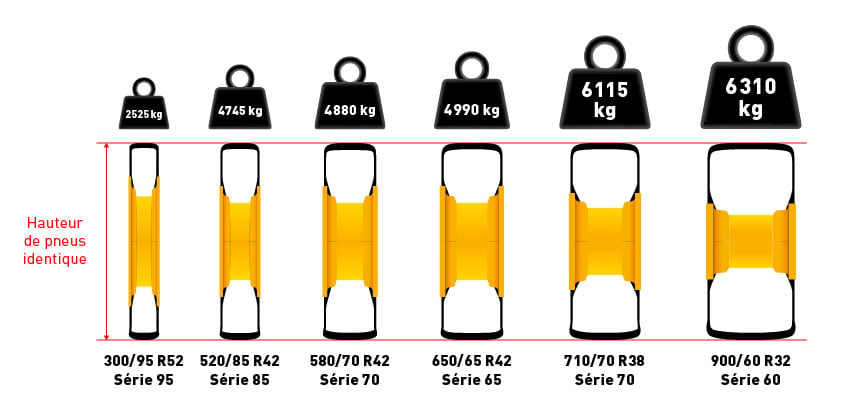

Load capacity depends on tyre size

By improving the relationship between tyres, engine power and the size of your implements, you can obtain a combination vehicle that will multiply its production capacity. Adapting the size of your tyres to the load will improve the traction capacity directly.

Working with a bigger contact patch with the ground, without increasing inflation pressure, while towing a greater load will effectively give much better results than your current set-up with standard size tyres.

Loads for a pressure of 1.6 bar and speed of 30 km/h

Changing tyre series allows you to increase

Changing tyre series allows you to increase

the load while protecting your soil better

2. Do your current tyres correspond to the specificities of the land on your farm?

Using the same machine, with the same tyre, for ploughing, then transport, then handling with a front loader in the farm’s courtyard is not the best way of avoiding premature tyre wear.

Field crops: which is the most suitable tyre?

Each type of farm corresponds to different tyre models, given that field crops and soft earth require tyres with the capacity to work at very low pressure, which provides greater traction, reduces slip and offers better protection for your soil.

High air volume tyres are perfectly suitable for work in the fields, because they increase the machine’s traction capacity and allow better transmission of power to the ground. They will help save time on your operations, even with heavy implements. Your soil is protected against compaction and your fuel consumption reduced.

Polycropping/livestock farming: which is the most suitable tyre?

This type of farm involves some work in the fields and some work on livestock farming management. It is obviously better to have several machines. During the fleet audit, you can define which machine should be used specifically for one type of activity exclusively.

By opting for the tyre that is best adapted to each activity, your tyres will last longer before needing to be replaced, whatever your activity. Certain handling operations place considerable strain on the front axle, such as work in the farm courtyard with a front loader, sharp, frequent turning on hard ground for which it is wise to have technical, reinforced tyres that you should reserve for this type of work only.

For mixed work divided between fields and transport, you can give preference to polyvalent agricultural tyres, but they must be designed to withstand this double activity, with longer lugs to provide better traction in the fields and more rubber to resist wear on the road better.

Irrespective of the type of land or activity, adopt eco-driving practices

The lifespan of your agricultural tyres will be very different if you cover long distances on the road, depending on your type of soil or the operations you carry out most frequently.

However, this lifespan may either be reduced by 50% or extended by 20% depending on how you drive.

The journey time you save is generally minimal when you drive at the maximum authorised speed, but the wear to the rubber will be significant, as well as fuel consumption, which will mount up by the end of the year. Overall, you have everything to gain by driving more slowly and calmly.

3. Improve the machine fleet efficiency by changing tyre technology

Even if they look alike, agricultural tyres can be very different, because they are generally designed for a certain type of activity. Their full potential may be attained in this activity, but not necessarily in another.

The more high-tech a tyre is, the more effective it will be for a precise activity, thus increasing considerably the capacity of your machines and your implements:

The major benefits of VF technology

It is possible to optimise the use of implements simply by changing tyre technology. VF tyres allow you to increase your load thanks to their reinforced structure and their highly supple sidewalls.

By opting for low-pressure VF tyres, like the VT-TRACTOR tyre, you obtain many benefits:

- Higher load capacity: the VT-TRACTOR tyre’s VF casing has been especially reinforced. It allows you to carry up to 40% more load compared to standard tractor tyres with the same dimensions.

- Time saving, because these high-tech tyres adapt to all types of ground: you no longer have to adapt pressure depending on the type of ground. A single speed scale has been kept on the recommended inflation tables (50 or 65 km/h).

- Soil preservation: compared to a tyre with the same dimensions, the VT-TRACTOR low-pressure tyre offers a much larger soil footprint to preserve your soil.

- The VF tyre limits slip, provides better traction and leads to fuel savings.

The superior technology used in multi-purpose tyres

With its reinforced casing, the VX-TRACTOR tyre is perfectly adapted to polycropping/livestock farming. It has better quality rubber constituents and 20% more rubber than a standard agricultural tyre, which makes it resistant to wear and gives it a longer lifespan:

- More rubber: Bridgestone’s VX-TRACTOR tyre has longer, more resistant lugs.

- An extremely robust casing: the structure of the VX-TRACTOR tyre has been reinforced to increase its load capacity. The exclusive S-LINE bead profile secures the tyre/rim connection.

- Improved tread design, it has 6 layers of rubber on the tread to guarantee better stability in all circumstances and offer increased resistance during transport by road or work on hard surfaces.

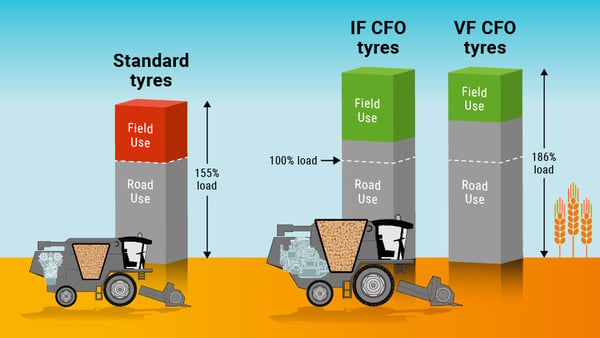

As for Bridgestone’s VT-COMBINE tyres, they contribute towards soil preservation during the harvest

- Optimised for soil preservation: the VT-COMBINE offers a large soil footprint with a lug contact patch that is 22% larger than for a normal tyre,

- Ability to work at low pressure: you can reduce pressure to as low as 1.8 bar during the harvest compared to 4 bar for a standard tyre.

- At a low inflation pressure, the S-LINE bead profile offers better dynamic properties and allows the tyre to work in tougher conditions, in particular with heavy loads and on sloping land.

- Resistance to load: with the same inflation pressure, the VT-Combine tyre lets you transport up to 86% more load compared to a standard tyre.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc.

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles:

- 5 essential techniques to optimise your agricultural tyres

- Agricultural tyre evolution, what impact on my farm?

- Agricultural contractors: improving quality of service with an adapted agricultural tyre

- Which vibrations are directly linked to agricultural tyres?

- Load comparison between standard agricultural tyres and VF tyres

- Impact of the loaded radius for my agricultural tyres

- VF agricultural tyres versus caterpillars: Pros and cons

- Why should you check your harvesting tyres before the start of the harvest?

- Which agricultural tyre makes it possible to avoid coming off the rim at low pressure?

- What is the impact of implement settings on tractor tyres?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *