Changing your tyres to adapt your tractor to its real use on your farm is extremely positive; it will optimise your vehicle and improve your efficiency. Whether it’s an increase in the volume of your tyres to carry more load or having the same width of tyre at the front as at the rear for better tilling, or to avoid compacting your soil, you should pay attention to the impact of the dynamic rolling circumference on your lead.

When you change tyres, you must calculate the lead for which you will use the real circumference of the new tyres and this is just when you need to be especially careful, to be sure to obtain maximum efficiency from your new tyre fitting. This is what you need to know about the dynamic rolling circumference:

1. What is the dynamic rolling circumference of tractor tyres?

The connection must be made with lead, which is the synchronisation of the front axle with the rear axle on a four-wheel-drive tractor with tyres of different dimensions.

For the calculation of lead, the exact circumference of your tyres is crucial. Unfortunately this new unloaded tyre circumference may vary in certain cases.

It is not the same when your tractor is stationary or at work, loaded or empty, with a high or low inflation pressure.

the tyre flattens out onto the ground

and its circumference changes

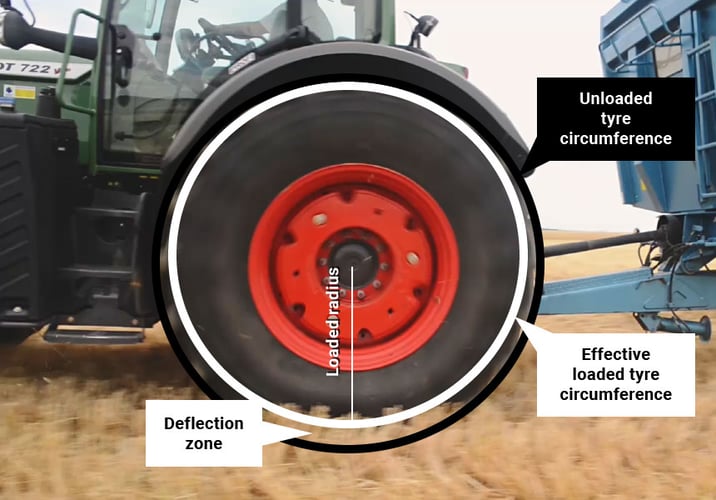

To understand correctly, you have to take into account the loaded radius, which corresponds to the measurement you can take between the centre of the axle and the ground.

The loaded radius varies depending on several factors, such as the tyre’s deflection capacity (a standard tyre is more rigid than a low-pressure VF tyre), the load, the torque or the speed.

When your tractor is at work, there is a difference between the tyre’s theoretical unloaded circumference and the loaded rolling circumference. The latter is effectively smaller, since the load will deflection the tyre (deflection zone).

and the real loaded circumference

2. What negative impact can the dynamic rolling circumference have on your lead?

If the rolling circumference is no longer the same when you have a different configuration in terms of load, torque, pressure or speed, this could mean that you are no longer within the correct tolerance range for lead, which is between 0.5% and 5%.

This may result in your lead ratio being lower than 0.5% or higher than 5%, given that optimal lead is 2.5% (or at least between 1.5% and 3.5%).

Technical explanation:

When the base of the tyre deflection into the ground, either due to a heavy load, torque, or a lower inflation pressure, its form is no longer perfectly round. A new real circumference, which takes account of your dynamic working conditions, then replaces the theoretical, perfectly round, unloaded circumference.

The calculation of the dynamic rolling circumference is complex, because the impact of torque or speed on the loaded radius cannot be measured manually on a moving tractor.

You can, however, make an approximate calculation just by taking into account the impact of your load and inflation pressure in the fields, with the implement engaged (in working conditions) to measure your loaded radius. This measurement will obviously be very different from our general technical data, with a maximum loaded radius at nominal pressure.

Approximate calculation of your dynamic rolling circumference

= Half the diameter + the loaded radius × 3.14116

The tyre’s deflection zone and the loaded radius change on the basis of real working conditions

1. When you transport heavy loads

When you transport heavy loads, the tyre will deflection into the ground under the effect of the weight, thus reducing the loaded radius. The loaded radius differs depending on the tyre technology, given that a low-pressure tyre is much more supple than a standard tyre.

A VF tyre gives you a low loaded radius, and thus a real circumference that is smaller than a classical agricultural tyre (with the same tyre dimensions).

2. When your implement is touching the ground

When your implement is touching the ground, you need a lot of torque for your tractor. The engine draws the machine forwards, but the implement will slow it down and the two opposing forces counter each other. The tyre is the element that transmit tractive force to the ground. So it sinks in to get a grip, which also reduces the loaded radius.

3. To avoid soil compaction

If you want to avoid soil compaction in your fields, you will reduce your inflation pressure significantly to around 0.8 bar. Once again the tyre sinks into the ground with a lower loaded radius.

It is possible that you are no longer within the tolerance range which was correct with your new, unloaded tyre in a static position.

What happens when you move out of the correct lead range?

The change in circumference may mean that you are no longer within the correct tolerance range, which will have a negative effect on tractor performance and cause operating irregularities.

What happens if your lead is higher than was intended for your tyre, and it moves out of the tolerance range?

- When the lead ratio is above 5%, it is excessively high and the rear tyres will have a tendency to slow down the front tyres which pull much harder.

- If, on the other hand, your lead ratio drops below 0.5% or becomes negative (lag), the rear axle will have a tendency to push the front axle. So the front axle slows down rather than pulling which causes mechanical heating of the front hub and an increase in slip at the rear.

Too low a lead ratio results in stress at the level of the drive train, causing considerable mechanical strain on the front axle.

If you insist on driving in such conditions, you are likely to damage the transmission and mechanical gearing and driving parts such as differentials, gear reducers, sprockets…

In addition, an incorrect lead ratio often causes abnormal wear to your tractor tyres and excessive slip in the fields, especially in wet conditions.

A minor difference of 0.5% is enough to cause the desynchronisation of the front and rear axles.

3. How best to manage the dynamic rolling circumference when you change tractor tyres

The lead range recognised as being correct by all the manufacturers is between 0.5% and 5%. If you wish to make the most of optimal traction and reduce the slip rate as well as your fuel consumption, you should be aiming for a lead ratio of 2.5% (or as close as possible, while remaining between 1.5% and 3%). with your new tyres.

By choosing to be as close as possible to 2.5%, you are certain not to suffer from the impact of variations linked to the dynamic rolling circumference, as you will stay within the right lead range despite these variations.

By being close to 2.5% when stationary, there will be less of a risk of having negative lead or lag (below 0.5%) or too much lead (above 5) when the tractor is on the move.

A good lead ratio brings many benefits both in terms of soil preservation and for the lifespan of your tyres, so it’s also good for your wallet.

A good lead ratio improves the tractor’s energy performance

With a 4WD tractor, the front tyres have to rotate slightly faster than the rear tyres to obtain a slight pulling effect and ensure the correct functioning of the tractor’s mechanical parts: engine, differentials, transmission…

This good synchronisation of the front axle with the rear axle optimises your tractor’s energy performance.

A good lead ratio optimises tyre wear life

Tyre wear is often accelerated by differences in rotation speed between front and rear tyres.

A good lead ratio allows you to save on your tyre budget, because you will need to replace your tyres less frequently.

The closer the lead ratio is to 2.5%, the less you will wear the tyre lugs, which means that your tyres will last longer.

A good lead ratio gives you excellent adherence

The agricultural tyre is the element that provides the link between the ground and the tractor, its lugs grip hold of the earth to transmit the torque necessary and make the vehicle move forward.

To obtain better traction, the lugs must adhere to the ground with a slip rate that is perfectly under control. Several factors can influence adherence, such as weather conditions, pressure, tyre wear and of course lead.

By aiming for a lead ratio of around 2.5% when you replace your tyres, you can control slip to guarantee optimal traction for your tractor.

To take into account the dynamic rolling circumference correctly, you have to accept the possible variation in the circumference of the tyre in working conditions, which may be linked to the load, the torque, the pressure or the speed.

If you calculate lead as close to 2.5% as possible when changing your tyres, you will have anticipated the possible variations and will be assured that despite these inevitable variations, you will stay within the right lead range, allowing you to work in optimal conditions.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc.

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles:

- 5 essential techniques to optimise your agricultural tyres

- VF agricultural tyres versus caterpillars: Pros and cons

- Why should you check your harvesting tyres before the start of the harvest?

- Which agricultural tyre makes it possible to avoid coming off the rim at low pressure?

- What is the impact of implement settings on tractor tyres?

- Fleet audit: what is the main benefit of agricultural tyres?

- Do you really use the full capacity of your VF agricultural tyres?

- Agricultural tyres: rules for managing the lead ratio

- Managing the load transfer to the front tyres in polycropping

- What are the signs of an incorrect lead ratio?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *