Given that improper lead can cause extremely rapid wear to your tractor tyres, you may rightly wonder whether this type of problem will be covered by the manufacturer’s warranty. The concept of mechanical lead is generally misunderstood and is linked to the varying rotation speeds of different sized tyres at the front and the rear on four-wheel drive tractors. You cannot consider that a correct lead ratio on a new tractor is the reference, it is generally calculated based on theoretical data, but once the tractor is in use, it’s mechanical lead is effectively likely to vary. This variation stems from multiple causes, affected by the tractor’s operating environment: load, inflation pressure, wear, tyre brand, in short, the lead ratio is not a stable, fixed index. You therefore cannot be sure that a problem with improper lead will be covered by your warranty.

In this article we look at elements that can cause improper lead, the consequences on the tyre warranty and how to solve this type of problem:

1. What do we know about lead?

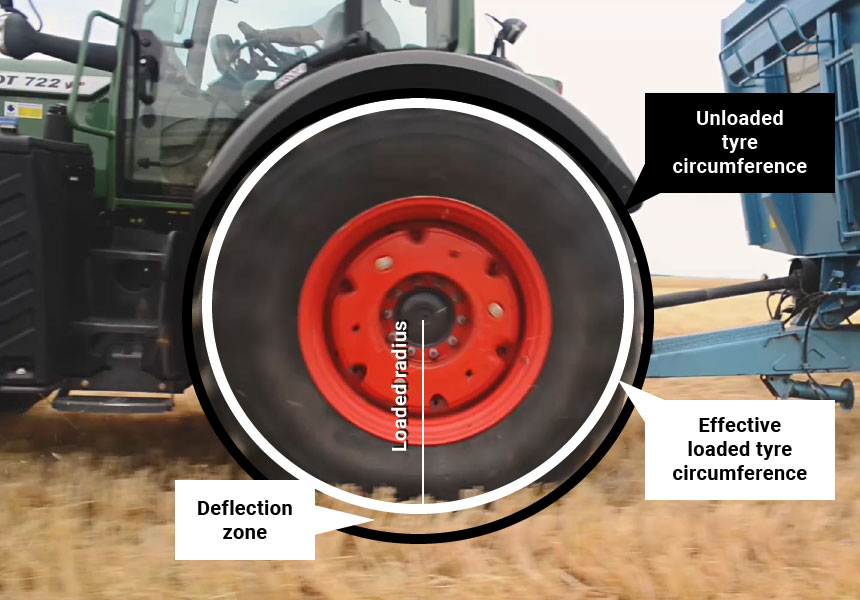

Lead refers to the difference in rotation speed between the front and rear tyres of a tractor whose wheels are not the same size. This difference is expressed as a percentage and has a significant impact on the correct mechanical functioning of your agricultural vehicle. In addition to ensuring the synchronisation between the front and rear axle of your tractor, a good lead ratio allows you to obtain optimal traction. It is calculated based on the machine’s drive ratio and the exact rolling circumference of the front and rear tyres.

with the rear axle, with unequal size tyres

In detail:

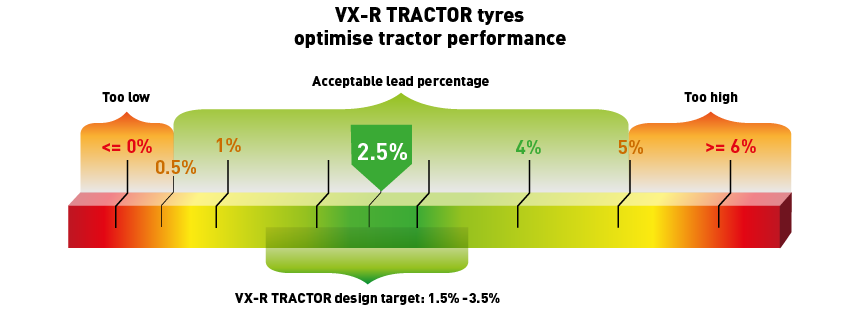

- A lead ratio of below 0.1% is too low

- A lead ratio of 5% or more is too high

- A lead ratio between 0.5% and 5% is considered correct.

Ideally, the lead ratio should be between 1.5% and 3.5%. To ensure optimal tractor performance, try to be as close to 2.5% as possible.

Lead does not depend on mechanical settings, but on choosing the right dynamic rolling circumference proportionality between your tyres, at the time of purchase.

2. What can cause improper lead?

Even if you are within the right lead ratio range when your tyres are new, several factors can affect mechanical lead during the working life of your tractor tyres. None of these should be neglected if you wish to avoid damaging your tyres prematurely.

Too much load or incorrect pressure settings

The load carried by the tractor is one of the main causes of improper lead. When the tractor has heavy loads to transport, combined with an insufficient inflation pressure, the weight exerted on the tyres may be excessive, which modifies the shape of the tyre and its rolling circumference. If, with the tyres originally fitted on your tractor, the lead ratio was already close to the acceptable limit, with new tyres and no load a small additional change in the tyre circumference can cause an imbalance, affecting the synchronisation between the tractor’s front and rear wheels.

Inappropriate pressure can also lead to excessive deflection in the tyres. This also affects their rolling circumference and consequently the tractor lead. Over or underinflated tyres can disturb the balance between front and rear wheels, causing improper lead and resulting in problems with traction and adherence.

Incorrect distribution of weight between front and rear

An incorrect distribution of weight between the front and rear of the tractor has an influence on lead. If the load is disproportionate on one of the two axles, you should expect a difference in rolling circumference for the tyres on the overloaded axle compared to the theoretical circumference. This affects mechanical lead and therefore the synchronisation of the tractor wheels. To maintain an optimal lead ratio, make sure that the load distribution between the front and the rear of the tractor is optimal.

Different brands or levels of wear between the front and the rear tractor tyres

Did you know that replacing a set of tyres on one axle can cause a problem with lead, even if you keep the same tyre size?

If new tyres are fitted on the front axle for example, whilst the worn tyres are kept on the rear axle, this can distort the lead ratio which is linked to the tyre’s effective rolling circumference. If this circumference changes because the new lugs are longer than the worn lugs, or if you fit the tractor with a different tyre brand, with shorter lugs, the proportionality relationship between the front and the rear changes, which can result in improper lead.

3. What are the risks of unsuitable lead?

Unsuitable lead is not without consequence. That is why it’s important to choose your tyres carefully, to maximise their useful life. Here are the main risks you face in the event of unsuitable lead.

Risk of accelerated wear to the front tyres and excess fuel consumption

Improper lead can cause premature wear to the front tyres.

When the lead ratio is too high, that is to say above 5% ; there is too much traction in the front wheels. The front axle pulls too much and is slowed down by the rear of the vehicle. The front tyres will tend to slip and sink into the ground if the soil is soft or wet. They will wear very rapidly and fuel consumption will increase significantly.

Risk of losing transmission power

An ill-adjusted lead ratio can also lead to less effective transmission. If the lead ratio is too low, i.e. below 0.5%, the rear axle will push too much. In this case, the front axle does not pull the vehicle, on the contrary it slows it down. This leads to the hubs overheating, stress at the level of the powertrain and considerable mechanical strain.

On the road, this problem can cause damage to the front axle pinions. When the lead ratio is too low, the latter are not correctly aligned, which can cause mechanical problems at the level of the pinions. If you hear a clicking noise when the front axle engages, this is a sign that the pinions are not corrected aligned. This can lead to serious damage to the pinions and result in mechanical repair costs for the front axle, which could have been avoided.

4. Can wear linked to tractor lead affect the agricultural tyre warranty?

Excessively rapid tyre wear can effectively affect your warranty. Abnormal tyre wear can lead to doubts as to the use of the tyres or the quality of the tyre fitting operation.

When tyres wear prematurely, this can indicate an underlying problem which raises the question of whether the tyres chosen are suitable for your machine.

This type of wear is not generally attributed to a manufacturing defect in the tyre itself. Manufacturing defects can often be identified as soon as you start using the tyre, whereas wear linked to tractor lead appears progressively over the period of use.

Premature tyre wear is in fact frequently due to incorrect use, or unsuitable operating conditions. This may include inappropriate tyre pressure, regularly overloading the tractor, an incorrect load distribution between front and rear axles or improper lead.

5. Certain tyres have been developed to obtain an optimal lead ratio

Bridgestone has developed tyres that are specially designed to obtain optimal lead on different agricultural vehicles. The manufacturer has worked specifically on the rolling circumference, to enable tyre fitting combinations resulting in a lead ratio close to 2.5%. This gives your machine the advantage of staying at the right lead ratio, even taking into account variations caused by overloading, pressure anomalies or progressive tyre wear.

The VX-R TRACTOR tyre ensures optimal lead

Bridgestone’s VX-R TRACTOR tyres are designed with a perfect lead ratio, with the theoretical objective of the manufacturer being 2.5%. The external use parameters may cause the lead ratio to vary between 1.5% and 3.5%, which remains an optimal range for all uses. This optimised configuration improves tractor handling and usability, as well as traction and the transmission of power to the ground.

The VX-R TRACTOR tyre combines technical and financial benefits

Reduced fuel consumption:

VX-R TRACTOR agricultural tyres have a specific design which optimises your tractor’s energy efficiency.

Better traction:

The innovative design includes a wider tread and a unique “Involute” lug profile. Its features lead to optimal traction, which improves the overall productivity and efficiency of your machine.

Better resistance to wear:

Designed with a very robust casing, with a greater volume of rubber and a plant-based oil compound which increases wear life, the VX-R TRACTOR tyre is more resistant and longer lasting.

A very good return on investment:

A purchase cost corresponding to the quality of the tyre, which is more robust and more reliable, offering greater work efficiency and a longer wear life.

In line with sustainable development objectives:

Developed using ENLITEN technologies, the manufacturing process aims to use 100% sustainable materials, with an optimisation of fuel consumption and great energy efficiency.

Choosing tyres which ensure good mechanical lead guarantees the durability of your equipment and the correct functioning of your agricultural vehicle. Otherwise you could run the risk of damaging your tyres prematurely or damaging the tractor’s transmission, without this being covered by the warranty. To avoid these problems, the best solution is to opt for high-tech tyres like Bridgestone’s VX-R TRACTOR tyre, specially designed to ensure an optimal lead ratio, offering increased durability and better traction. By investing in this type of tyre, you improve efficiency and overall tractor performance.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc.

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles:

- 5 essential techniques to optimise your agricultural tyres

- Fleet audit: what is the main benefit of agricultural tyres?

- Do you really use the full capacity of your VF agricultural tyres?

- Agricultural tyres: rules for managing the lead ratio

- Managing the load transfer to the front tyres in polycropping

- What are the signs of an incorrect lead ratio?

- Impact of the dynamic rolling circumference of agricultural tyres

- What is the impact of the section width of your agricultural tyres

- Do my tractor tyres have a wide enough footprint?

- Can my agricultural tyres help reduce my fuel consumption?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *