Fuel represents 30% of energy consumption in farming and is one of your farm’s highest annual expenses. The good news is that you can reduce the bill by making a few simple adjustments and by adopting the right overall management strategy.

It’s more a question of choice than a question of means. By following simple advice on a regular basis, you can improve your profitability and your revenues. This is how...

Your fuel savings are directly linked to your farm management

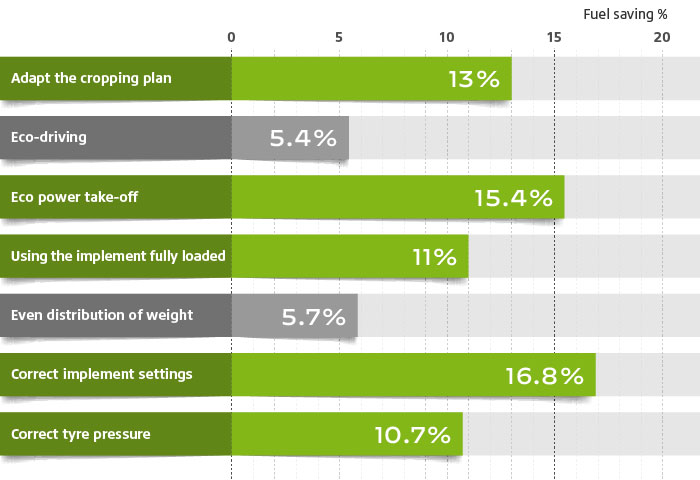

Reduce engine speed, drive slower on the road, adjust tyre pressure, fine-tune the different tools, manage weight distribution better….. these are all small forgotten tasks which make the difference in the long run and which make the difference, above all, at the end of the year in terms of your profitability.

Here are the three main ways to reduce consumption:

1. Better management of crop farming methods

Give up ploughing and adopt simplified sowing techniques: You must decide whether it is absolutely necessary to work with the highest fuel consuming equipment, like the rotary harrow or plough. You can often simplify the crop farming method without any consequence on your yield. Tilling depth is also decisive in your tractor’s fuel consumption, so by tilling the upper soil level only, the power required is reduced along with consumption, without any loss in yield.

Avoid work sessions that are too short: If the work can be completed in a single day rather than in three half days, this will lead to savings by limiting transport and idle engine time which represents about 15% on average per operation.

2. A strategic choice of equipment

Always optimise the size of tractor attachments: suitable tools result in savings of between 5% and 8%.

Adapt the tractor as far as possible to the work to be carried out: using the right ballasting, opting for large, low-pressure tyres and adapting tyre pressure precisely to suit the load are important steps leading to real savings after a full day working on a given activity.

Always adapt engine power as precisely as possible: use the lowest engine speed possible, in general 1700 or 1800 rpm. By using the right gear ratio and working 300 or 400 rpm below the maximum speed, it is possible to save 4 l/h in fuel when ploughing.

Only ballast if necessary and in this case ballast optimally: the right weight management can lead to savings of 5% to 8%. Ballasting is essential to increase tractor grip and limit slippage. Optimal ballasting means only ballasting when necessary; with the right ballast, there is no excess consumption linked to slippage, but the additional weight will have to be removed at the end of each job to avoid the tractor having to use power unnecessarily to transport it when there is no major tractive effort required.

3. A more tactical use of equipment

Adopt eco-driving techniques permanently with all your agricultural machinery: savings of 10% to 20% can be made by adapting your driving.

Pay attention to the quality of the fuel: Use of fuel from the bottom of the tank is strongly discouraged. You should first fill up the tank with higher quality fuel with increased combustion and then wait two hours, so you don’t clog up the motor with sludge and suspended condensation water, ideally filling up the tank in the evening after work. Draining the tank regularly will allow you to get rid of condensation water.

Carry out regular tool maintenance and adjustment operations: by fine-tuning a well-adapted tool you can make savings of up to 30%: Sharpen cutting edges and regularly grease mobile parts following manufacturer recommendations. Worn plough shares or a conditioner that is too tight can lead to a considerable increase in consumption.

Carry out regular tractor maintenance and adjustment operations: using an engine test bench to test each tractor makes it possible to optimise engine adjustments: for example, nearly one out of two tractors is supercharged; by adjusting the injection pump correctly, you can save nearly 1000 litres each year over 600 working hours. Changing filters, cleaning the cooling circuit…. etc. are just as important.

By choosing the right tyres and systematically using them at the right pressure you can save 10% to 20% in fuel with good tractor tyres, which represents savings of €4,000 per year by choosing a better agricultural tyre for all your agricultural vehicles.

Systematically use economic power take-off when possible: economic power take-off is optimal for work that requires little power (spreading fertilizer, spraying). This option gets you to the rotational speed required with a lower engine speed.

Find out more:

Discover the testimony of 9 farmers who have tested different fuel saving solutions using their agricultural machinery.

Download the results by clicking on the button below

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need for your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to agricultural tyres.

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *