Even if it’s not really recommended, there are several situations in which it may be interesting to increase the pressure in your tractor tyres beyond their limit, to manage operations better or protect your tyres against a load that is too heavy.

This could allow you to work with heavier implements, to work with a front loader or on sloping land in dry conditions, or even to reduce the number of trips back and forth at harvest time with the trailers by loading them up more.

In short, increasing pressure really makes sense in certain cases.

In this article we look at the specific situations when you can increase the pressure (while staying within the acceptable tolerance range) without going too far which could have negative consequences for your tyres.

In which cases can increasing pressure be beneficial?

Current trends are seeing a move towards a general decrease in inflation pressure to protect the soil and avoid excessive compaction which can be harmful to future yields. So it may seem out of place to try and increase pressure as this would be counterproductive.

However, in certain very specific cases, and with limits to be respected, increasing pressure beyond what is recommended for your tyre (speed rating and load index which require maximum pressure) may make sense economically and be beneficial.

Here are the cases where an increase in pressure makes sense:

You are equipping your tractor with a larger, heavier implement

To compensate for the load transfer that will take place onto your tractor tyres, you will naturally have to increase the inflation pressure.

This is normal, but this will be beneficial in terms of productivity only if the weather has been dry for a long period and the ground is sufficiently stable for its bearing capacity to cope with the additional weight and the higher inflation pressure without suffering from compaction.

For example: After the summer harvest, you can work with a wide Chisel plough. This will not require much tractive force, so by increasing the pressure in your tyres, you will be able to drive faster.

In this case you can cover the surface area of your field quicker with a wider implement and therefore save time in completing your operations.

You are working on a hard surface with a front loader

If you are conducting handling operations in the farm courtyard, you can equip your tractor with a front loader, a spade or a fork for transporting fodder or cleaning out the stalls for example.

The load transfer to the front axle will be significant when you fill up the trailers or store hay high up and the increase in pressure on the front axle will be perfectly adapted to the situation.

In this case, you can increase pressure because no speed is required and your tyres will be much more resistant to load.

with a front loader on hard ground

You work on sloping land in dry weather conditions

If certain of your fields have steep slopes, it is important to increase the inflation pressure to cope with the load transfer to the trailing tyre axle.

Of course, this can only be done in dry or very dry conditions to avoid the compaction that would be linked to the increase in pressure.

In this case, increasing pressure is highly recommended to avoid the tyre accidently coming off the rim (which would mean that you have to replace both tyres on one axle) with additional costs which would wipe out any benefit of working at low inflation pressure.

During harvesting, if you need a load bonus

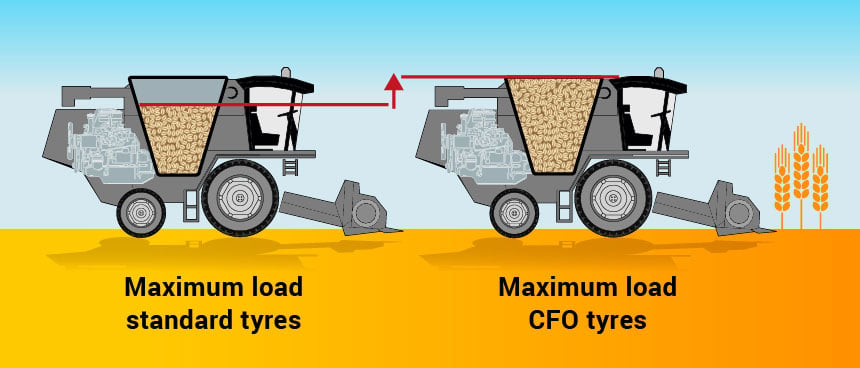

During harvesting, the impact of the weight of the loaded harvester on tyres is certainly the moment when the management of pressure is the most important.

If you do not have tyres that are adapted to this work, or if you do not have the right inflation pressure in these tyres, you will not be able to fill up the hopper and you will have to unload the harvester into the trailers more frequently if they are available.

To avoid having to stop operations, a tyre that allows you to increase pressure will let you fill up the hopper more while reducing speed.

1. More pressure at low speed with standard tyres

The speed rating and load index marked by the manufacturer on your tyre are recommendations which provide a framework or limit within which to work with total peace of mind.

In specific circumstances, it is possible to increase pressure for all the situations described previously, but in most cases this will require a reduction in speed.

Pressure compensates for load

If the tyre crushes at its base into the ground due to the excess load and was not designed for this purpose, the internal structure of the tyre will be damaged and quite rapidly it will become unfit for use and you will have to replace it.

By increasing inflation pressure beyond the limit, if the tyre was actually designed for this purpose, you will be able to compensate for the load and maintain the tyre’s normal working capacity.

Certain standard tyres have been designed to resist a heavier load and a higher inflation pressure

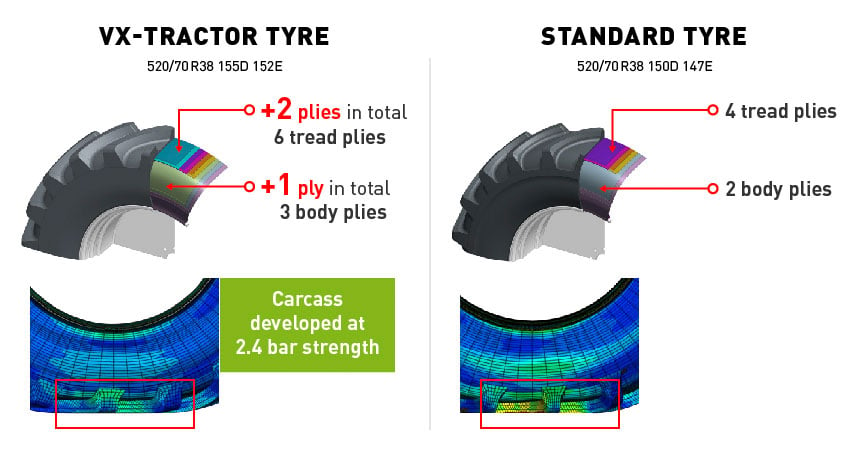

Bridgestone’s VX-TRACTOR tyre is in this category of reinforced standard technology tyres which are produced using a solid casing, giving them a much higher load capacity.

For example, certain tyre sizes such as the 520/70 R38 have 3 casing plies and 6 plies for the tread:

to cope with heavier loads and higher inflation pressure

It was designed to work at a wide range of pressure settings from 0.6 bar to 2.4 bar which is much higher than most standard tyres (1.6 bar on average).

It gives you the exceptional possibility of working with a load bonus and a pressure of up to 3 bar at 10km/h for work with a front loader for example.

2. Certain tyre technologies are more resistant

VF technology was designed for working at low pressure and protecting your land against compaction when you work in wet conditions, when the soil is soft or you need torque to work without causing soil compaction in your fields.

However, whilst these low-pressure tyres have the capacity to resist load while remaining at a low inflation pressure, of keeping this low pressure on the road and in the fields without any alteration to their structure, they are also capable of working at a higher inflation pressure when necessary.

VF technology can also cope with a high inflation pressure

Time is precious during harvesting. If you use your tractor for transport, it may be wise to increase the pressure in your VF tyres to win time.

For example, the VT-TRACTOR tyre has an indicated pressure range of 0.6 bar to 1.6 bar. But you can increase pressure to 2 bar without altering its load capacity with a travel speed of up to 70 km/h maximum for transport by road with trailers during the harvest.

If you systematically carry out loading operations on the grass strips at the edge of your fields, the high inflation pressure in your tyres will not have any negative effect on the soil in your fields.

to avoid compacting the soil with high-pressure tyres

3. With tyres designed for cyclic loading operations

It is during harvesting that the use of high-pressure tyres certainly makes the most sense, to be able to continue working while filling up the hopper if the trailers are not available.

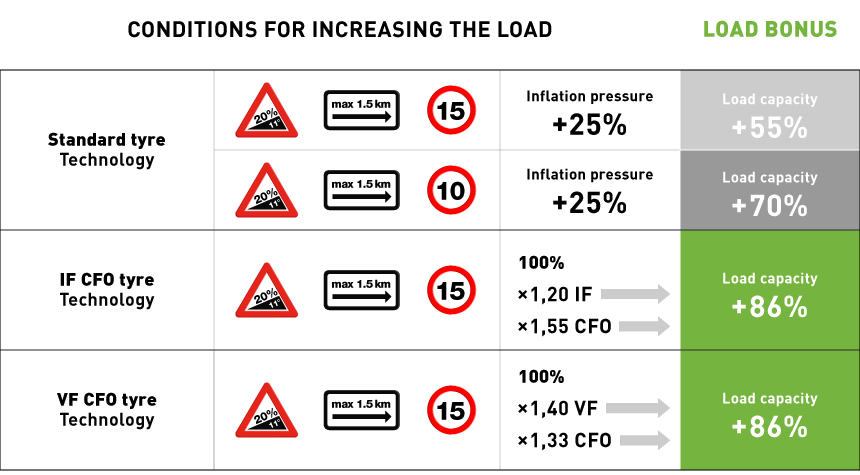

If the quality of your standard tyres is good enough, you can work with 25% more pressure to absorb the cyclic load linked to filling up the hopper.

IF VF CFO technology increases the load without increasing pressure

To go even further, it is possible using VT-Combine CFO tyres with IF or VF technology to increase the maximum load during cyclic operations at a speed of 15 km/h without increasing pressure, which will be a major advantage in terms of load but also for soil preservation purposes.

To obtain a load bonus without affecting your tyres, there are nonetheless some specific conditions of use to be respected:

- Do not work on slopes with a gradient of more than 20%

- Do not exceed a speed of 15 km/h

- Do not drive for more than 1.5 km with a full load

while keeping the same pressure

EXAMPLE - VT-Combine 900/60 R32 CFO - 2.4 bar

A VT-Combine tyre size 900/60 R32 CFO with a pressure of 2.4 bar allows you to carry 8,000 kg per tyre at up to 40 km/h.

But in the case of a cyclic load (when there are no trailers to unload into) this 900/60 R32 CFO VT-Combine tyre, again at a pressure of 2.4, can carry up to 1,3175 kg per tyre by just reducing speed to between 10 and 15 km/h.

4. Be careful, not all tyre models allow you to go beyond the inflation pressure marked on the sidewall

Certain tyre models are not designed to go beyond the limits indicated on their sidewalls, so before increasing pressure you must be sure that the manufacturer authorises a load bonus with your tyres.

The tyre’s internal technology or the casing’s resistance capacity is not visible at first glance, and working with brands such as Bridgestone, which have brought a high level of technology to their tyres, is a guarantee of success in your operations, even in difficult conditions.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice that you need about your farming tyres. They will help you to maximise your productivity with information on all things relating to tyres: inexpensive tractor tyres - technical data for farming tyres - advice on farming tyre pressure - solution to avoid soil compaction - sprayer tyre pressure - Why and how to ballast your tractor tyres - when to use twin wheels - the mechanical causes of abnormal wear - cheap agricultural tyres - etc.

To take it a step further and increase the profitability of your farm, the tractor tyre experts has prepared a free, highly detailed, ebook which explains the essential role of farming tyres on your productivity.

Most people who read this article have also read some of the following articles:

- 12 simple tips to better manage the pressure of your agricultural tyres

- Non-adjusted tyre pressure will lead to damage to my tyres

- How much does it cost you not to adjust the pressure of your agricultural tyres?

- How to get rid of the tractor tyre pressure adjustment step

- Farming tyres, pressure monitoring or full Central Tyre Inflation System CTIS

- 7 advantages of low-pressure tyres compared to normal tyres

- What is the right inflation pressure for any tractor tyre

- The keys to working at very low pressure with your agricultural tyres

- Understanding your tractor tyres’ pressure -load -speed link

- Tank Air Wheel rims, to inflate tyres in 1 minute

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *