You certainly think that this problem does not arise, because you do not currently take the time to change the pressure between the road and the fields, often due to lack of time and because this operation seems secondary to you compared to the urgency of the work that you are going to do.

Yet the financial consequences of the failure to adapt your tyre pressure between different types of ground are as high as the cost of early replacement of a pair of tyres. And this is merely a question of wear and tear, without taking into account fuel consumption linked to excessive slippage or the rolling resistance of a tyre that is not at the right inflation pressure.

However, there is a very simple solution if you don’t ever want to have to manage tyre pressure again between the road and your plots of land. Explanations.

1. What are the consequences when your tractor tyre pressure is not adjusted from one ground to another?

Within a single day, the pressure of your agricultural tyres will vary several times depending on the type of work to be carried out and the type of farm:

- Work in the field with trailed, semi-mounted or mounted implements

- Transport by road

- Dry or wet ground….

Here are three possible cases to consider when you are driving with tyres with the wrong pressure.

1. The consequences of underinflation on the road

The risks when you drive regularly on the road with underinflated tyres are numerous and sometimes irreversible. When you accelerate on asphalt, the internal temperature of the tyres will rise, which inevitably leads to heating of the rubber and premature wear to your tractor tyres.

As for rolling resistance, this will also increase because the contact surface between the road and the agricultural tyre will be much greater than normal. This will lead to overconsumption of fuel by about +5%, or even more if travel by road is long. In the worst case, a sudden puncture may occur if the casing is already showing signs of weakness.

The solution therefore consists in increasing the pressure, because if underinflated, the tyre bounces on the asphalt, causing an abnormal wear and tear of one of the two lugs and the shoulders. You can overinflate your tyres up to 2 bars to save around 30% of fuel, especially if you drive a lot on the road.

2. The risks with underinflated tyres in the fields

In the fields, the pressure of agricultural tyres must be checked before each intervention in order to avoid damaging them rapidly and to avoid the risk of accidents. A tyre whose pressure is too low compared to manufacturer recommendations may incur internal deteriorations which are not necessarily visible from the outside. Sometimes, underinflation may lead to irreversible damage to the casing of the tyre, because the tyre no longer maintains its initial form. The more the structure is deformed, the more the butyl deteriorates and is in danger of breaking, making your tyres unusable.

With low pressure, the extremity of the sidewalls of the tyre will be in direct contact with the ground and will incur the same deteriorations and the same shocks as the tread. A branch or a root is enough to create a cut, thus leading to a sudden puncture of the tyre, and therefore the immobilisation of your agricultural machinery leading to major expenses.

To conclude, driving with underinflated tyres represents a real danger to the extent that the stability of the tractor in the turn and in braking is reduced, above all if the tractor is loaded. This is explained by the deformation of the tyres which is unfortunately not compensated by the pressure. In all cases, the risk of an accident cannot be overlooked.

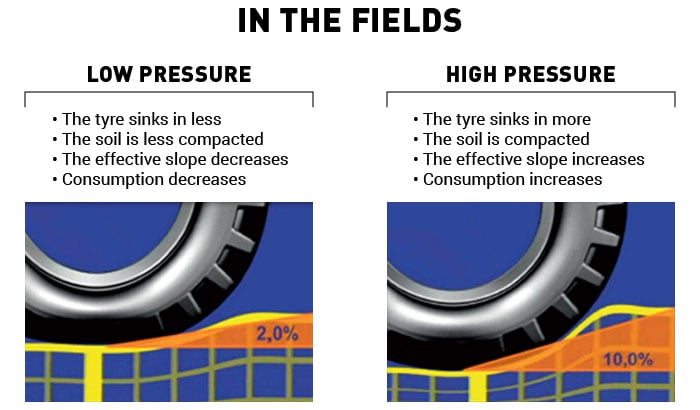

3. What happens with overinflated tyres in the fields?

It’s not just underinflated tyres which can cause problems when working in the fields. Over inflation of your tractor tyres is not recommended either, because it leads to slippage, excess fuel consumption and premature wear to your tyres.

On dry ground, a tyre inflated to well above the recommended pressure will not have much grip, because its tyre-soil footprint is limited. Basically, the contact surface between the lugs and the ground is insufficient, making traction much less efficient.

In wet conditions, over inflation will lead to slippage, making self-cleaning of the tyre more difficult and leading to the formation of ruts, which in turn leads to additional work to restore the field to its original condition and obtain a productive plot of land. As the squashing of the tyre is reduced, it sinks further into the ground before meeting resistance and increasing the slip ratio. If the slip ratio is higher than 15%, the structure of the soil will tend to deteriorate with the surface layers sliding horizontally. When the slip ratio reaches 30%, this increases the risk of getting stuck in the mud, leads to 20% extra consumption of fuel and premature wear of the tyres.

When you work in the fields, an overinflated tyre will lead to more rolling resistance by sinking in until it meets resistance. When the tyre sinks into the ground by 1cm more in depth, this has an impact of 10% more fuel consumption.

2. VF tyres: the best solution to avoid repeated pressure adjustments

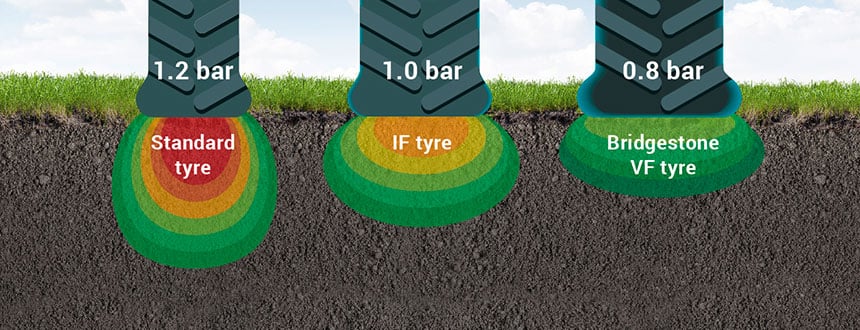

If you don’t have time to adjust your agricultural tyres to the right pressure when you go from field to road, your best solution is to use VF technology tyres. These are manufactured with very high-tech components and have a more flexible and resistant sidewall.

As the name indicates, IF (Improved Flexion) and VF (Very High Flexion) casing tyres provide a high level of suppleness on both asphalt and wet ground. In addition to this major faculty, these new technologies are designed to bear greater loads.

With the same pressure, an IF tyre can bear an additional load of 20% whereas a VF tyre can bear up to 40% more. There is another non negligible benefit to the VF tyre; its polyvalence on all types of land. So no more tyre pressure adjustments between field and road.

Designed with longer lugs, these new generation tractor tyres offer optimal driving comfort.

If you still have doubts about this technology, here are 4 good reasons which might incite you to use wide low-pressure VF tyres:

1. A greater carrying capacity

Thanks to their reinforced sidewalls, VF technology tyres are much more flexible and resistant. They can bear up to 40% more weight than a standard agricultural tyre.

In addition, it is possible to reduce their pressure to increase the contact surface with the ground. With wider implements, less passes are required, leading to lower costs.

2. The end of permanent pressure adjustments

With VF technology tyres, you won’t need to change the pressure of your agricultural tyres anymore when you go from field to road and back again. So no more problems linked to the adjustment of pressure when going from one type of ground to another. This progress represents both a real comfort and a considerable time saving for farmers who are always pushed for time or who don’t know what pressure to use depending on the type of soil.

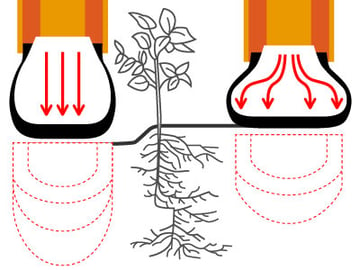

3. Better soil preservation

Soil compaction is one of the main concerns facing farmers. There are different solutions to deal with this problem, but the most efficient one is the use of wide VF tyres.

WIDE FOOTPRINT =

Preserving the soil, less compaction and better yields!

Thanks to their design, VF tyres contribute not only to the preservation of your soils, but also to the optimisation of your yield. To resume, their low pressure reduces soil compaction and slippage.

4. Optimal productivity

The use of wide, low-pressure tyres allows you to optimise the traction of your agricultural vehicle, so you can work faster than with classical agricultural tyres.

With their wider tyre-soil footprint and their higher load index, VF tyres allow you to cover more hectares in one day. This will improve your productivity while reducing your fuel consumption.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice that you need about your farming tyres. They will help you to maximise your productivity with information on all things relating to tyres: inexpensive tractor tyres - technical data for farming tyres - advice on farming tyre pressure - solution to avoid soil compaction - sprayer tyre pressure - Why and how to ballast your tractor tyres - when to use twin wheels - the mechanical causes of abnormal wear - cheap agricultural tyres - etc...

To take it further and increase your farm’s profitability, the Experts du pneu tracteur have prepared a free highly detailed eBook which explains the essential role of your agricultural tyre on your productivity.

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *