Reducing the load on each axle is one means of limiting soil compaction, the other is to spread the load over a larger surface.

By using light machinery, you protect your soil.

Moreover, lighter machines have a lower rolling resistance, allowing you to reduce your fuel consumption during transport activities. Lighter machines improve your productivity. So why the need for ballasting?

Why do I need to ballast my tractor?

Ballasting consists in increasing the mass of your tractor reversibly. It is particularly useful, or even essential, if you have a light tractor, for activities requiring a lot of traction such as ploughing for example. The traction capacity of a machine is directly related to its weight. Ballasting increases the tractor’s grip. Slipping is reduced. which reduces damage to soil, increases the efficiency of your work (reducing working time) and the durability of your tractor tyres (reduced wear to tread lugs).

To determine whether your tractor requires (additional) ballasting, you can calculate the slip ratio. Ballast can also be used to increase the stability of your machine. This can be useful if your land is sloping, as is the case for vineyards.

The weight must be placed as low as possible on the machine to lower the centre of gravity and increase stability.

How to ballast my tractor?

There are two types of ballast, ballast with metal mass and ballasting agricultural tyres with water.

- Metal mass ballast, consists in placing metal weights (generally cast iron) on the tractor itself or on its wheels (axle or hub).

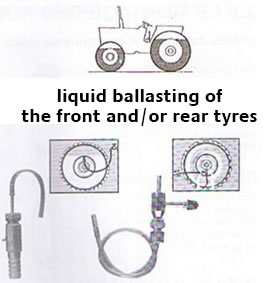

- Water ballast consists in partially filling the tractor tyres with water.

The type you choose will depend on how you are going to use your tractor.

Metal weight ballast

When should you use a metal weight ballast?

Metal weight ballast is recommended if you wish to spread the load between the front and rear of your tractor, which cannot be achieved with water ballasting of agricultural tyres.

Moreover, the use of weights is more flexible as it allows you to adjust the number of cast weights to the weight required. Their installation is laborious as it requires lifting materials to handle the heavy weights.

Rules for metal ballasting

If your tractor needs to carry or pull a light load, most of its weight should be on the rear. However, if the load is heavy, the weight should be spread equally between the front and rear of the tractor (see the table below for approximate weight distribution).

| DISTRIBUTION OF WEIGHT BETWEEN THE FRONT AND REAR AXLES IN % | ||||||

| Light load | Medium load | Heavy load | ||||

| Front | Rear | Front | Rear | Front | Rear | |

| 2-wheel drive | 25% | 75% | 30% | 70% | 35% | 65% |

| 4-wheel drive | 35% | 65% | 35% | 65% | 40% | 60% |

You can check the accuracy of your ballast by measuring the load transfer with weighing equipment.

Weighing the tractor’s rear axle

Weighing the tractor’s rear axle

Be careful not to over ballast your tractor, as this would increase your fuel consumption and the wear to your machinery and your tyres (due to higher pressure in the tyre casing).

Water ballast

When should you use water ballast?

Use water ballast if you wish to ballast your tractor permanently. This will not enable you to adjust the loads between the front and the rear of the tractor. Before use, you must check the compatibility with your tyres (check the manufacturer guidelines). They must be equipped with an air/water valve. Water ballast is more economical than adding weights.

Rules for using liquid ballast

To fill your tyres with water, place the tyre valve topmost. This way the air will exit as your fill the tyre. Fill the tyre with a mixture of water and antifreeze (if you are using a tubeless tyre, you must also add an anti-rust product to the mixture) up to ¾ of the height of the tyre, or up to the level of the valve.

Adjust the pressure of the remaining air.

As there is now less air, it is important to check the pressure more often than usual. This system will reduce shock absorption and comfort (it is possible to compensate by adjusting the tractor suspension). Before ballasting your tyres, always refer to manufacturer guidelines for filling procedures.

Checking the ballast of my agricultural tyres

You can check the ballast by observing the tread marks on the soil.

- If the tread mark is not clearly defined (figure 1), this indicates a high rate of slipping which means that your tractor is insufficiently ballasted.

- If the tread marks are too deep (figure 2), there is not much slipping, but there is excessive soil compaction.

- Finally, if you can see clearly defined surface tread marks (figure 3), there is sufficient ballast.

Adequate ballasting will enable you to gain maximum performance from your agricultural tyres while avoiding damage to your soil.

The brigestone-agriculture blog is written by tractor tyre experts who are available to provide you with the advice you need to maximise your productivity (agricultural tyre technical data, agricultural tyre performance, solutions for avoiding soil compaction, sprayer tyre pressure, etc.)

To take it further and increase the profitability of your farm, pneu tracteur provides a free, highly detailed eBook which explains the essential role of the agricultural tyre in your productivity.

Most people who read this article have also read some of the following articles:

- 7 keys to know the impact of ballast on agricultural tyres

- What are the consequences of excessive weight on my tractor tyres?

- Distribution of weight: ballast with liquid in the tyres or cast iron weights

- What is the right load distribution for my tractor tyres?

- What are the disadvantages of using water ballast in tractor tyres?

- Incorrect ballasting: what are the risks for my tractor tyres

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *