Ballasting is often indispensable for your tractor and mounted implements to ensure that your operations take place in the best possible conditions.

Depending on the work to be done, you will need to use different implements whose mass ratio for the tractor will more or less significant.

The risks of incorrect ballasting differ considerably depending on your situation, if your tractor is too light compared to the tractive force required you will slip or experience handling problems, especially if the ground is wet.

On the other hand, if you overballast you run the risk of rapid wear to your tractor tyres, excessive soil compaction or even serious problems with the front axle if you have amassed too much additional weight.

Sometimes it takes a long time to carry out the right adjustments, to add or remove weight, yet the risks are greater than you imagine:

- The invisible risks: soil compression and compaction,…

- The immediate risks: a problem with the front axle, or less efficient braking on the road

In all these cases the financial consequences can be significant.

There are two types of incorrect ballasting: overballasting and underballasting.

1. THE RISKS OF OVERBALLASTING

Excess additional weight, uneven distribution of weight on your tractor or water ballasting on a tractor with no implement can have major consequences on your productivity, because overloaded axles may result in increased fuel consumption, excess soil compaction on your land and thus have a negative effect on the normal development of your crops.

The damages do not concern only your yield, but also your equipment. In detail, excessive ballasting may generate the following problems:

Mechanical breakdown or irreversible deflection of the tyres

When you use very heavy tooling, just within the limit of your tractor’s power, you will be obliged to add weight to ballast your tractor to ensure the balance of your towed implement and maximise your machine’s tractive force. But adding unevenly distributed or excessive mass may generate other problems, because excessive weight on your agricultural tyres could lead to accelerated deterioration or, worse still irreversible material damage.

Too much weight at the front of the tractor, for example, can lead to risks of mechanical breakdown such as breaking the front axle. In this case, the risk of the tractor being immobilised is inevitable as you will have to have repairs carried out on site or be towed away, which will cost you much more than the time necessary to check the correct weight distribution before starting work.

In addition, excessive ballasting can lead to damage to the internal structure of agricultural tyres or irreversible deflection. If you attach mounted or semi-mounted tools that are too heavy or if you overload your trailer, the mass of the tractor will squash your back wheels. On hard soil, the lugs may bend under the tractive effort and break, or the deformation linked to the squashing effect may occur laterally on the sidewalls which are pushed beyond the limits intended by the manufacturer and there is a real risk of internal breaks in the casing, which will mean that you have to replace the tyres that have been squashed by this mass.

In order to avoid this sort of inconvenience, the only solution when using very heaving tooling is dual mounting. Dual wheels allow you to bear a greater weight and spread out the tractive effort more evenly, thus reducing slippage and premature tyre wear.

Tyre wear and extra fuel consumption

A bad weight distribution between front and back axle would endanger the stability of the towed implement and considerably increase rolling resistance, leading inevitably to excess fuel consumption.

There are two possible cases:

- Too much weight on the back axle: this makes your tractor less easy to handle, because the front tyres have less grip and it is hard to control the vehicle. What’s more, the excessive load on your back tyres accelerates wear due to slippage, which in turn leads to extra fuel consumption.

- Too much weight on the front axle: it is the front tyres that will wear too quickly due to slippage linked to the difficulty in pulling the trailer.

In both cases, excessive ballasting at the front or back will cost you dearly with an early replacement of your prematurely worn tyres, given that at any moment you run the risk of breaking the butyl, rupturing the casing, or even bursting the tyre if it comes into contact with a sharp object (root, silex…).

Risk of accidents on the road

Overballasting on the road can lead to the risk of accidents. For example, if you try to compensate for the excess load with tyre pressure that is too high, you increase the risk of tractor rollover, because the grip coefficient will be reduced. In poor climatic conditions, your tyres will lose grip, particularly on the road when breaking, because the overall trailer mass ratio on the front axle will be far greater than your vehicle’s capacity and the resistance of your front tyres.

Speed problem with water ballasting

Ballasting tractor tyres with water is not always the right solution. The main disadvantage of this technique is that you leave the water in your tyres for the whole season. The dead weight generated by this mass of water has a large impact on your fuel consumption throughout the year, even when it is not necessary. The financial loss is therefore considerable.

Unlike ballasting with weight, water ballasting is not suitable for travel at speed on the road. The excessive speed could result in a swing effect linked to the movement of the water mass within the tyres which could cause your tractor to pitch when going around bends and therefore destabilise tractor and trailer, above all if the ballasting has not been done evenly.

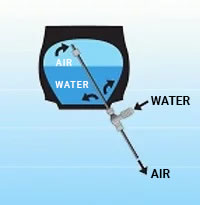

For water ballasting to be optimal, the following rules must be respected:

For water ballasting to be optimal, the following rules must be respected:

- Do not exceed 75% of the tyre volume

- In winter: mix with a 30% antifreeze solution (calcium chloride) for protection up to -30

Excessive soil compaction

Implements that are too heavy and excessive ballasting with metal can lead to soil degradation. The excessive load squashes your tyres, you compensate by increasing tyre pressure which in turn provokes excessive compaction of your crops and leads to the appearance of ruts.

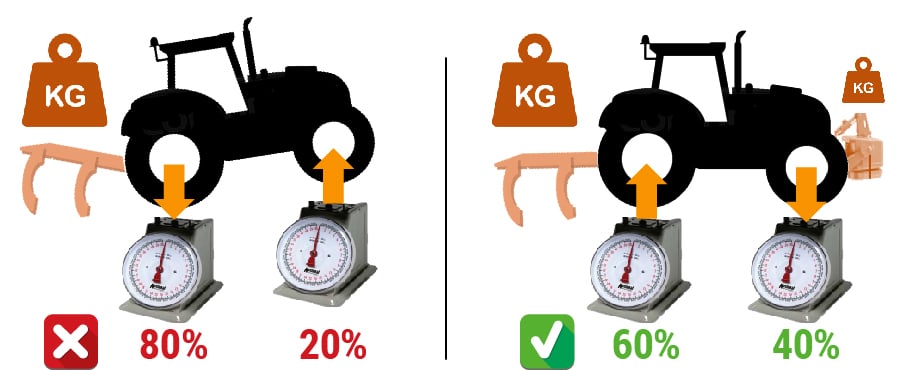

As excessive ballasting is not without consequences both in terms of equipment and financially, it is wiser to get it just right when ballasting. In theory, the general consensus is that the weight distribution ratio for a tractor is 35 to 40% on the front and 60 to 65% on the back.

2. The risks of underballasting

The other possibility is that the weight of the tractor is insufficient compared to the weight of your tooling. Underballasting means that you cannot compensate the imbalance of your towed implement as a whole, it’s often the front axle that does not have enough grip, the back axle being overloaded in general, because it bears the load transfer from the tooling alone. The risk of slippage increases, which slows down your work rate while wearing your agricultural tyres rapidly.

Reduced manoeuvrability

To determine whether your tractor is underballasted, just look at your tyre footprint on the ground. When it is not clearly defined or barely visible, this means your tyre grip is too limited. The ballasting is insufficient, which can impact the manoeuvrability of your tractor, as the tyres will tend to slip or not react so well when changing direction (especially on heavy ground).

Excessive slippage

When the metal weights or the volume of water used for ballasting are insufficient, the tractor is likely to slip excessively. A Slip ratio of more than 8 to 10% leads to horizontal sliding of the topsoil and damages its structure. This also results in a loss of time and efficiency, but above all causes premature wear to the tyres. With an actual distance covered by your tyre that is greater than the distance driven by your tractor, you are likely to use up to 20% more fuel with a slip rate of 30%.

Imbalance of the towed implement

If you only use water ballasting, this may not be enough to ensure the correct balance of your towed implement when driving with a very heavy load, because you will need a good distribution of weight between your tractor tyres and with water the ballasting of the front axle will always be a little low.

As we have seen in the preceding paragraphs, for a four-wheel drive tractor the correct front-to-rear axle weight ratio should be a maximum of 35 to 40% on the front and 60 to 65% on the back.

This weight distribution makes it possible to optimise safety, improve the general balance of your towed implement and ensure good motricity.

RESULT: you preserve your equipment and your soil

A good solution for increasing the load: VF technology tyres

There is another more efficient way to avoid overballasting, which consists in using tyres designed for heavy loads. By choosing low pressure VF tyres, you can make do with less ballasting and thus lighten the overall weight of your implement without necessarily using additional metal weights.

They are able to increase their contact patch with the soil, which allows you to increase the load and work at very low inflation pressure while preserving your tractive force and the soil.

Example of load transfers possible with VF equipment

CLAAS AXION 930-340 CV TRACTOR with VT-Tractor tyres

Additional equipment: remote inflation system SODIJANTE

| BRIDGESTONE VT-Tractor tyres | FRONT | BACK |

| Tyre size | 710/60 R34 | 900/60 R42 |

| Weight of the tractor alone | 5,780 Kg | 7,060 Kg |

| Use of two mounted implements | TF 1500 KUHN hopper = 1,500 Kg + load transfer X 1.7 = 2,500 Kg |

KUHN harrow with load transfer = 6,400 Kg |

| I.E. A TOTAL LOAD WITH MOUNTED IMPLEMENTS OF 21,740 KG | ||

On the RAOD 2.1 bar

In the FIELD 0.8 bar: the optimal pressure to avoid soil compaction despite the load.

The Bridgestone-agriculture blog is written and administered by tractor tyre experts who are available to provide you with advice on your tyres. They will help you to maximise your productivity with information on tyre related topics: Technical data for agricultural tyres - Agricultural tyre performance - Advice on agricultural tyre pressure - Solutions for avoiding soil compaction - Sprayer tyre pressure - Why and how to ballast your tractor tyres - etc.

To take it one step further and increase the profitability of your farm, Bridgestone-agriculture provides a free, highly detailed eBook hich explains the essential role of the agricultural tyre in your productivity.

Most people who read this article have also read some of the following articles:

- 7 keys to know the impact of ballast on agricultural tyres

- How and why to ballast your tractor tyres or agricultural tyres

- What are the consequences of excessive weight on my tractor tyres?

- Distribution of weight: ballast with liquid in the tyres or cast iron weights

- What is the right load distribution for my tractor tyres?

- What are the disadvantages of using water ballast in tractor tyres?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *