Numerous studies have shown a loss of yield linked to excessive soil compaction ranging from 20% to 50% in the most extreme cases. If you think about it, which machines have the most impact on the soil in your fields? Obviously, it’s the harvesting machines. Which machines operate with high pressure in their tyres and the heaviest loads? Obviously, it’s the harvesting machines. A loaded combine-harvester can weight up to 40 tonnes.

If you add fully loaded trailers with tyres inflated to 3 bar, the harvesting campaign is really what will have the most effect on your soil fertility. However, there are tyres which can really make the difference, by working at a low inflation pressure despite the unavoidable load in your hopper.

Here is how to manage a harvesting campaign while preserving your soil:

1. The harvest campaign: soil compaction that is very bad for soil fertility

Fertile soil is first and foremost soil that is in good health, which is to say that the structure is crumbly and well aerated. This allows the roots to develop freely and encourages rapid crop growth. Unfortunately, several factors may impact the quality of your soil and make it less productive.

The heaviest machines

To really understand what this represents, we need to take a look at the weight of the machine. When empty, the weight of a combine harvester is an average of around 20 tonnes and may exceed 24 tonnes if you add the cutting bar. When loaded, the weight can increase to more than 37 tonnes, given that the load capacity of a hopper of 15,000 litres may be up to 12 tonnes. With a good load distribution you have 75% of the weight at the front and 25% at the rear, which represents 28 tonnes on the front axle and 9.6 tonnes on the rear axle. If you add the impact on the soil of the trailers and tractor convoys to empty the hopper, the results in terms of soil compaction are significant.

Repeated toing and froing across the land

In addition to the load, the repeated toing and froing of an agricultural vehicle over the same area accentuates the compaction by 5 to 10% for each additional passage. This percentage is just an indication and depends on several factors, in particular the type of soil and the type of agricultural machinery. In any case, the harvest campaign is clearly one of the operations that mobilises the heaviest machines. And the efforts required to restore the land will be massive.

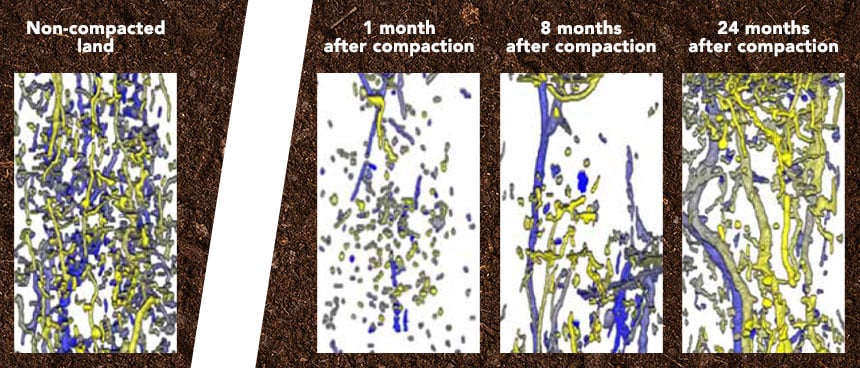

by earthworms after soil compaction

The natural reconstitution of the soil is a very slow process. You will need to programme mechanical soil aeration work, which will help to break up compacted soil, encourage the return of biological life and improve the root development of your future crops.

This will allow water and air to circulate within the soil once more and therefore make it possible to recreate in-depth water reserves which are essential during the dry season.

2. Only work when the soil conditions are good

Another solution that allows you to reduce the loss of soil fertility consists in working only in the best weather conditions.

Before beginning operations, it is highly advisable to check that your soil has dried out completely.

When you work in wet conditions, this effectively further accentuates soil compaction or causes soil sealing. In any case, these phenomena are at the origin of damage to the soil structure and soil life.

To work in the best conditions and preserve your soil, you must check the state of your land before starting operations. If the earth is too soft and sticky, it’s safe to say that it’s still too wet to cope with the passage of heavy machinery.

Whatever the tyre technology you use, too much moisture content inevitably causes more slip, accelerates soil deterioration and increases fuel consumption. It is therefore preferable to wait until the soil has properly dried out.

3. Make the strategic choice to reduce your load

To compensate for the weight of the machines, it is normal to increase tyre pressure, which is one of the main causes of soil damage. It is possible to make the deliberate choice to limit the weight of a harvesting machine by loading the hopper less.

Limit the load or aerate the soil?

In principle, choosing to limit the load can be an advantage, if you compare the slight gain obtained by carrying the maximum load against the 20% loss of yield in your field linked to soil compaction over the following years.

The extra fuel cost you will incur by working a bit longer with a harvester that is less loaded, or extra inbound and outbound trailers that are less loaded, is always going to be less than the quantity of fuel necessary for soil aeration operations.

4. No tractors or trailers on the land to unload the harvester

You can protect your soil better by avoiding driving over the land with you tractors and full trailers.

The trailers are effectively designed to bear load, but generally with an inflation pressure of over 3 bar. They rarely have low pressure tyres unlike your tractor, so they have a major impact on compaction.

It may take you a little bit longer to reach the trailers at the edge of your field, but this is just a question of organisation: you can unload at the side of the field each time your harvester passes by.

On large farms, you also have the possibility of using a transfer trailer with very wide low-pressure tyres which will make the trip to the trailers at the edge of the field without compacting your soil.

5. Choose low-pressure tyre technology which allows you to remain at 1.8 bar despite the load

In order to resist the load, you must set your tyres at the right inflation pressure. As we mentioned before, there are roughly 28 tonnes weighing on the front axle when loaded. To compensate for this weight, tyre pressure has to be set at 3 or 4 bar with standard tyres.

To preserve the quality of your soil, certain agricultural tyre ranges allow you to work at a pressure of between 1.8 and 2.4 bar, despite a heavy load.

This is the case namely for the VT-Combine tyres developed by Bridgestone:

to a standard tyre with the same load

Possibility of working at a very low inflation pressure

CFO technology tyres can operate at a pressure range of 1.2 to 2.4 bar. When working at low pressure, their footprint becomes bigger, which means that there is a better distribution of load to the ground compared to a standard tyre.

VT-Combine tyres have an S-Line bead profile with excellent dynamic properties. This S-Line bead profile ensures that the tyre is perfectly airtight when you work at low pressure and the tyre is crushed by the weight of the load.

Exceptional resistance to load

Bridgestone’s VT-Combine IF VF CFO tyre has been specially engineered to adapt to the different harvesting operation requirements. It has a more elaborate casing which is more robust and solid than in standard tyres. Its ingenious design means that it can bear a load bonus of up to 86% more load, depending on the tyre dimensions, as compared to a standard tyre.

Here is a comparative table with different tyre sizes for use at an inflation pressure of 2.4 bar:

| Size | Standard tyre load capacity at 2.4 bar |

VT-Combine IF VF CFO tyre load capacity at 2.4 bar |

LOAD BONUS | ||||

| 650/75 R32 | 8,295 kg | 10,075 kg | +21% | ||||

| 800/65 R32 | 9,870 kg | 11,625 kg | +18% | ||||

| 900/60 R32 | 10,855 kg | 13,175 kg | +21% |

Optimal traction

The lug’s contact surface with the ground is 22% larger than standard tyre lugs. These lugs provide optimal traction and help reduce soil damage thanks to their “involute” design.

Their large soil footprint preserves the soil in your fields, thus encouraging soil fertility.

A longer wear life

The composition of the rubber includes a compound that is more resistant to wear. The manufacturer effectively uses plant based oils instead of certain petroleum oils.

This special compound ensures exceptional durability for Bridgestone’s VT-Combine IF VF CFO tyres, even in extreme conditions.

CONCLUSION

To preserve your soil and ensure long-term yields, it is essential to avoid soil compaction during the harvest.

Rather than working with a high inflation pressure, it is better to use low-pressure tyre technology or load up your hopper less and reduce the inflation pressure. Reducing pressure by 1 bar on average will have a significant impact on the soil and contribute towards preserving the fertility and structure of the soil on a long-term basis.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice that you need about your farming tyres. They will help you to maximise your productivity with information on all things relating to tyres: inexpensive tractor tyres - technical data for farming tyres - advice on farming tyre pressure - solution to avoid soil compaction - sprayer tyre pressure - Why and how to ballast your tractor tyres - when to use twin wheels - the mechanical causes of abnormal wear - cheap agricultural tyres - etc.

To take it a step further and increase the profitability of your farm, the tractor tyre experts has prepared a free, highly detailed, ebook which explains the essential role of farming tyres on your productivity.

Most people who read this article have also read some of the following articles:

- 12 simple tips to better manage the pressure of your agricultural tyres

- How much does it cost you not to adjust the pressure of your agricultural tyres?

- How to get rid of the tractor tyre pressure adjustment step

- Farming tyres, pressure monitoring or full Central Tyre Inflation System CTIS

- 7 advantages of low-pressure tyres compared to normal tyres

- What is the right inflation pressure for any tractor tyre

- The keys to working at very low pressure with your agricultural tyres

- Understanding your tractor tyres’ pressure -load -speed link

- Tank Air Wheel rims, to inflate tyres in 1 minute

- Can you go beyond the recommended pressure for your tractor tyres?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *