What is the best way to preserve your soil? The latest wheel technology combined with the highest technical level of VF agricultural tyres takes us one step further on the path towards soil preservation, obtaining a fuel reduction of up to 20% and reducing wear to your tyres.

This innovation allows you to increase pressure by 1 bar simultaneously in all 4 wheels in less than a minute, without getting out of the cab. This gives you the possibility of working in the fields with a low inflation pressure, then taking to the road with an additional 1 bar of pressure. You will save 15 minutes on pressure adjustment time and possibly increase your agricultural tyres’ lifespan by 50%.

This article tells you all you need to know to make soil preservation on your farm a reality at last.

1. Why is technology one of the keys to your profitability?

To improve profitability, you don’t just need a powerful tractor and the best tyre technology, you also need to be able to harness the best of this equipment’s potential.

If you work with standard tyres, you will certainly encounter many problems, the main difficulty being the frequent inflation pressure adjustments and if you opt for an average pressure for all uses, the consequences will have a real impact on your productivity, time spent, tyre lifespan and as such your finances.

High pressure in the fields

= High slip ratio

It is important to manage your slip ratio by reducing inflation pressure when you work in the fields.

Overinflation leads to high rolling resistance and increases the slip ratio, which means that your tractor will lose traction capacity despite the engine power. This damages the tyre tread and increases fuel consumption, making you lose a lot of time.

Technology helps you solve this problem just by pushing a button in your tractor cab.

Excess soil compaction

= lower yields

Excess soil compaction will lead to loss of yield and productivity. It is often caused by an incorrect load distribution on the axles or incorrect inflation pressure.

High pressure can lead to excess soil compaction and encourage the formation of ruts. This significantly reduces crop development by blocking the circulation of water and air in the different layers of soil.

The right tyre technology combined with the correct pressure settings will resolve this problem.

On the road a longer braking distance

= less control

Driving on the road with a low inflation pressure and a heavy load will lead to a deformation of the tyre which affects stability during turning and braking. This may increase the risk of the tyre bursting, above all at high speed, and cause a loss of control of the trailer during sudden braking.

It is therefore important to have tyres inflated to an optimal pressure, based on the load, to maintain a correct level of safety despite your speed.

A VF technology tyre provides the solution and makes it possible, when at the right pressure, to reduce the braking distance thereby avoiding the worst scenario.

Short tyre lifespan

= more frequent cost of replacement

To minimise tractor tyre wear, it is important to adopt the right pressure settings depending on your load and the type of ground.

Pressure must be lower in the fields, then adjusted to be higher on the road. Underinflated tyres on the road can cause the component materials to overheat and separate, whereas excess pressure in the fields can lead to increased slip and rapid wear to the rubber.

The most rapid cause of tyre wear is an inflation pressure that is not suitable for the load or ground on which the tractor is driving. This rapid wear leads to frequent replacement costs and reduces your profitability.

Technology can eliminate all these problems and nowadays offers a complete solution so that you can have optimal pressure in all circumstances.

A VF tyre like the VT-TRACTOR allows you to carry heavy loads at low pressure, both in the fields and on the road, and combined with a wheel with an air tank and a remote inflation system, can add 50% more lifespan to your tyres, while preserving your soil.

A lifespan of up to 50% longer for your tyres while preserving your soil

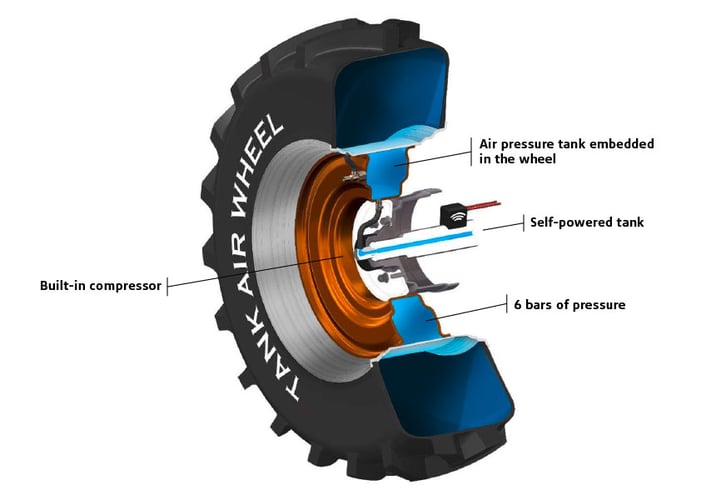

2. The Tank Air Wheel rim: a 6 bar air tank at the ready

Sodijantes Industrie has launched a new rim and wheel technology known as the Tank Air Wheel. This technology is complementary to remote inflation systems which have already brought many advantages:

- Soil preservation: during work in the fields, remote inflation systems allow you to reduce tyre pressure when driving to limit soil compaction and inversely you can increase pressure on the road without having to get out of the cab.

- Optimisation of traction: remote inflation facilitates the adjustment of pressure settings when you enter the field. You can reduce the inflation pressure in your tyres to increase their soil footprint and enlarge the lugs’ contact patch with the ground.

- Fuel savings: when working in wet conditions, you will be able to adjust tyre pressure easily thanks to the remote inflation system. This will reduce slip, leading to fuel savings.

- Reduction of tyre wear: the remote inflation system limits premature tyre wear, because it allows you to have an inflation pressure that is perfectly adapted to each situation (load, type of ground, weather conditions…).

An air tank is embedded in the wheel, making it possible to inflate agricultural tyres in a few seconds.

This technology allows you to modify tyre pressure rapidly, going from low pressure for work in the fields to higher pressure for transport. This technology, which reduces the tyre inflation time, leads to fuel savings, protects the soil, increases the tyres’ lifespan and improves handling during transport.

A revolutionary device

The novelty with this revolutionary device is the pressurised air tank in the wheel which serves as a booster and makes it possible to go almost instantaneously from 0.8 bar to 1.8 bar, i.e. around 1 bar more.

The Tank Air Wheel offers an exceptional inflation time thanks to its built-in, self-powered compressor which does not require any further installation on your tractor.

The tank contains several litres of air at 6 or 7 bars, which will be injected into the tyre in less than one minute, thus saving you a lot of inflation time.

3. VT-TRACTOR and Tank Air Wheel: the highest level of tyre and soil preservation

The VT-TRACTOR tyre was designed to work at very low pressure. It has very supple, reinforced sidewalls which mean that it can operate at a pressure of as low as 0.8 bar, even if you carry heavy loads.

This high-tech tyre developed by Bridgestone has a longer, wider soil footprint to provide better grip for the lugs and optimal traction.

More efficient, less time wasted

The Tank Air Wheel was designed to store immediately available pressure to facilitate going from field to road. This system allows you to inflate the 4 wheels simultaneously without getting out of the cab so that you can always drive with the right inflation pressure. During work in the fields, you can decrease pressure to limit rolling resistance and slip, allowing you to preserve your soil better and reducing tyre wear.

On the road, VT-TRACTOR tyres combined with the Tank Air Wheel offer you better control of the tractor (braking, steering…) since you can increase pressure on the way, either by pushing a button on the control unit in the cab or by pre-recording the “road” and “field” settings. Having tyres that are always at the right pressure limits wear and wins you thousands of extra hours of use.

CONCLUSION: The association of Bridgestone and Sodijantes technologies, i.e. respectively the VF VT-TRACTOR tyre and the Tank Air Wheel, leads to better performance and efficiency in the fields and on the road. Thanks to research and development it is possible to push the boundaries of agricultural tyre performance to achieve better soil preservation and improve your long-term yields.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice that you need about your farming tyres. They will help you to maximise your productivity with information on all things relating to tyres: inexpensive tractor tyres - technical data for farming tyres - advice on farming tyre pressure - solution to avoid soil compaction - sprayer tyre pressure - Why and how to ballast your tractor tyres - when to use twin wheels - the mechanical causes of abnormal wear - cheap agricultural tyres - etc.

To take it a step further and increase the profitability of your farm, the tractor tyre experts has prepared a free, highly detailed, ebook which explains the essential role of farming tyres on your productivity.

Most people who read this article have also read some of the following articles:

- 12 simple tips to better manage the pressure of your agricultural tyres

- Pressure: it’s the volume of air in the tractor tyre that counts

- Non-adjusted tyre pressure will lead to damage to my tyres

- How much does it cost you not to adjust the pressure of your agricultural tyres?

- How to get rid of the tractor tyre pressure adjustment step

- Farming tyres, pressure monitoring or full Central Tyre Inflation System CTIS

- 7 advantages of low-pressure tyres compared to normal tyres

- What is the right inflation pressure for any tractor tyre

- The keys to working at very low pressure with your agricultural tyres

- Understanding your tractor tyres’ pressure -load -speed link

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *