The optimisation of your equipment is one of the main sources of savings for your farm. This is particularly true for parts of your equipment which are subject to wear linked to use, your tractor tyres being the best example.

Ideally, we would all like slow and regular wear to extend the lifespan of our tyres as much as possible. 450 additional hours for a tyre represents more than just a small saving …

Imagine that you could gain 800 hours by mounting the latest generation tyres!

Here, in detail, is how to limit wear and the factors to take account of in choosing a tyre that will last the longest:

1. The 3 causes of wear linked to use

There are many reasons why your tyres may wear rapidly, but these are the three main ones:

1. Frequent use on the road

A tractor spends on average 25% to 40% of its time on the road, depending on the logistics of operations and how far away the fields are. However, the road is certainly where most wear is caused, particularly due to the road surface which is very abrasive for the rubber.

The irregularity of the ground, braking and accelerating are factors which influence the wear of an agricultural tyre. The surface of the road is effectively much harder than the earth and every time you brake or accelerate this increases the wear to your rubber.

High speeds when loaded generally lead to overheating of the rubber and can make it fragile, which is why it is always preferable to drive at a slower speed than authorised by the speed index of your tyres.

2. Incorrect tyre pressure

There are two possibilities:

UNDERINFLATION. When the tyre is underinflated, it bounces on the ground, provoking abnormal wear of the lugs (one out of two lugs is worn) and the shoulders.

On the road, a pressure that is too low can lead to heating of the tyre materials. If this situation happens too often the overheating leads to a deterioration of the structure of the tyre which can result in the separation of the different rubber, nylon, rayon and metallic components.

OVERINFLATION. Too high a pressure can also lead to premature wear to your agricultural tyre. The tyre effectively swells out and the central part of the tread is over solicited, which results in localised wear to the tips of the lugs.

3. Excess load

Driving your tractor with a load that is not adapted will inevitably result in tyre wear. By transporting loads that are too heavy, you increase solicitation of the tread, the sidewalls and the tyre casing which, with repetition, leads to permanent deformation of the tyre structure. This deformation will accelerate the overall wear to the tyre.

When driving with a heavy load, it is advisable to reduce your speed to decrease tread solicitation. By doing so, you will limit the heating of the tread and as such tyre wear.

To avoid damaging your tyres rapidly, it is essential to check that the load index of your agricultural tyres is adapted to the maximum loads that you transport. To do this, you just need to consult the load index table supplied by the manufacturer.

2. The 3 causes of wear linked to mechanical problems

Geometrical faults are one of the main causes of wear to your agricultural tyres.

If tyre wear is uneven, the chances are this is due to a mechanical problem. For example, if you notice that the front tyres are more worn that the back tyres, or that the tyres are worn only on one side with a right or left symmetry, you need to check:

- The front axle

- The wheel alignment

- The play in the steering ball joints

- The play in the bearings.

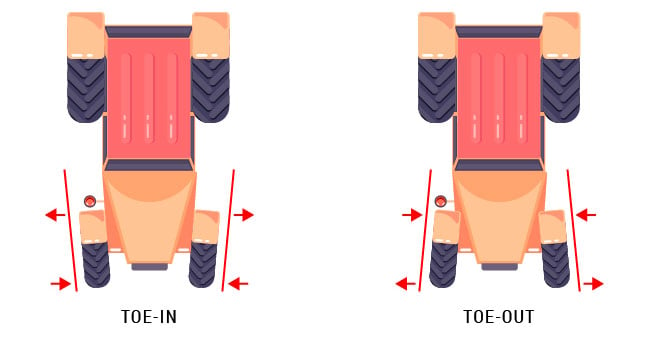

The mechanical reasons that can cause this type of wear are numerous, but the demands placed on the front axle on sinuous roads, or due to repeated knocks incurred by the front axle during operations may cause a problem with parallelism (toe in/toe out) or camber.

1. Lack of parallelism

This is a question of the progressive disalignment of the geometry of the wheels compared to the tractor’s driving direction. Whether you are in the fields, on paths or on roads in poor condition, an agricultural tyre takes on many knocks and bumps. The same applies when you cross over ruts or drive in very tracks that are too deep and affect steering.

This is a question of the progressive disalignment of the geometry of the wheels compared to the tractor’s driving direction. Whether you are in the fields, on paths or on roads in poor condition, an agricultural tyre takes on many knocks and bumps. The same applies when you cross over ruts or drive in very tracks that are too deep and affect steering.

A problem with parallelism can be put right by carrying out regular checks. You can correct it with setting adjustments when you spot one of the following problems:

- You notice abnormal wear to one side of the tyre

- Your tractor has a tendency to pull slightly to the right or to the left

- Your tractor swings to one side or the other of its own accord

- There is more resistance in the steering after a right turn than after a left turn (or the other way round)

- There is abnormal vibration when you increase speed on the road.

2. Problem with the camber angle

If you note that your wheel is not vertical to the ground, you have a problem with the camber angle. Ideally, you must adjust your tyre so that it is perfectly vertical, which is to say that the tread must be as flat as possible on the ground.

There are two types of camber problem:

Positive camber: when the top of the wheel points outwards from the tractor compared to the vertical axis, wear is concentrated on the outer section of the tyre.

Negative camber: when the wheel is tucked inwards, the wear is greater on the inner portion of the tyre.

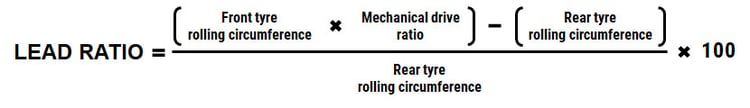

3. Incorrect lead

Lead is the synchronisation of the front axle with the rear axle of your 4-wheel drive tractor, depending on the dimension of the tyres.

Correct lead (between 1 and 3.5%) ensures optimal tractive force and avoids premature wear to your agricultural tyres. If you notice that your front tyres wear more rapidly than your back tyres or the other way around, this may be a result of incorrect lead.

There are two forms of incorrect lead:

Lead of more than 4 or 5%: the front axle undergoes mechanical stress since the rear axle slows down the front axle. In addition to steering problems and the risk of mechanical deterioration, your front tyres will wear faster than your back tyres.

Negative lead (lag) of below 0%: the front axle loses efficiency since the rear axle will push the front axle of the tractor. There may be a lot of slippage at the rear when you accelerate.

Mechanical stress leading to wear to the sprocket grooves

To calculate your tractor’s lead, you must first refer to the manufacturer’s manual and find the “mechanical ratio of the front axle” for your vehicle. You must then apply the following formula:

Lead = [(Front tyre rolling circumference X Mechanical ratio of the front axle – Rear tyre rolling circumference) / Rear tyre rolling circumference] X 100

For example:

- REAR mount: 650/75/R38 a with a rolling circumference of 5760 mm.

- FRONT MOUNT: 600/65/R28 with a rolling circumference of 4450 mm.

- Mechanical ratio of the front axle: 1.325.

Calculation of lead: [(4450 x 1.325) - 5760) / 5760] x 100 = 2.36%

The lead of 2.36% obtained in this example is perfectly adequate. By opting for larger wheels than the original mount, you may modify the lead and in general improve your efficiency.

3. Causes of wear linked to natural ageing

Mechanical problems are not the only causes of wear to agricultural tyres. The latter effectively have a limited lifespan over time due to the natural ageing of the tyre components.

There are two types of ageing:

Physical ageing: this usually corresponds to the effects of fatigue linked either to a situation that is too static or too dynamic, and can result in a modification of the structure of the polymers or crystallisation.

Chemical ageing of the rubber: this corresponds to a deterioration in the chemical structure of the polymer. There are many chemical ageing processes that may be linked to exposure to chemicals, such as solvents or hydrocarbons, but are more often of an environmental origin, such as excess water, oxygen, the ozone, the temperature and the light.

The ageing of tyres through oxidation

Oxidation leads to the breaking of bonds in vulcanised rubber structures based on natural rubber. Agricultural tyres therefore tend to become too supple under the effect of oxidation, which makes the rubber more sensitive to external aggressions and knocks.

Thermal ageing in the absence of oxygen

Under the effect of high temperatures, numerous reactions may occur in the absence of oxygen (if the tyres are stored in the presence of water or oil for example):

- Hardening of certain components

- Softening of the rubber following the thermal decomposition of the polymers and hydrolysis of the structures that are sensitive to water.

Ageing by ozonation

Vulcanised rubber contains double molecular bonds which are subject to solicitation in environments containing ozone, even in low quantities. Ozone can create more or less cracking depending on the temperature and humidity rate in the air.

The effect of sunlight on tyres

Small cracks may appear when the rubber is exposed to prolonged sunlight (tractor regularly packed in full sunlight for example).

It is therefore better to shield your tyres from UV rays.

Fatigue linked to use

Over time, an agricultural tyre may show signs of strain which generally takes the form of fissures. Several factors are involved in the wear and deterioration of the mechanical properties of the rubber, such as speed, pressure, climate, load, accelerations/decelerations or even the driving surface (road, path, field).

4. Which are one of the tyres that currently offer better resistance to wear?

Replacing your tractor tyres represents a major budget. To avoid having to change them just after 2000 hours, the best solution is to opt for recent, more technological models incorporating materials which are resistant to wear such as the VX-Tractor tyre.

This category of tyre satisfies all your needs, both in terms of durability and in terms of productivity. They are perfectly suitable for a multitude of different tasks both in the farmyard and in the fields. Thanks to their innovative technologies, they have improved capacities in all areas:

High load capacity

Bridgestone’s VX-Tractor tyre is capable of carrying heavy loads with a higher inflation pressure of up to 3 bar. These tyres have a solid casing designed to limit internal stress, which gives them optimal resistance.

Exceptional traction

With its patented technology and a wide tread footprint, this tyre provides considerable traction, which improves your productivity during work in the field. Thanks to the ingenious design of its “Involute” lugs, there is less of a displaced soil effect than with traditional lugs. It was developed to limit slippage and soil compaction during traction.

Longer life and reduced wear over time

But its main advantage is certainly its durability. It has a new component, containing vegetable oils, which improves resistance to wear as well as using up to 20% more rubber to obtain longer, wider and deeper lugs which guarantee greater resistance to wear and therefore a remarkable lifespan.

To learn more about ways to increase your farm’s productivity, bridgestone-agriculture has created a comprehensive eBook on the topic which is available for you to download for free:

Bridgestone-agriculture Blog is written and administered by tractor tyre experts who are available to provide you with advice on agricultural tyres. They will help you to maximise your productivity with information on all things relating to tyres: inexpensive tractor tyres, technical data for agricultural tyres, solutions for avoiding soil compaction, sprayer tyre pressure, why and how to ballast your tractor tyres, when to use dual-wheels, the mechanical causes for abnormal wear, discounted agricultural tyres, etc...

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *