We don’t talk about it much, but rolling resistance is specific to your tractor tyres, their pressure, their form, the type of surface encountered, the level of ground humidity and type of trailed implements (weight, width, mounted, semi-mounted, foldable). In short, it’s a phenomenon that you encounter every day without really knowing the parameters and the implications, yet it has a direct impact on your slippage rate, soil preservation, equipment wear, time spent and above all on your fuel consumption.

Here are a few explanations to help you understand and manage rolling resistance better, reduce fuel consumption and as a result improve your profitability…

The surface on which you drive has enormous significance, because resistance is very different depending on the type of ground. Loose soil obviously does not produce the same effect as the bitumen on the road which is extremely hard.

There are therefore two types of rolling resistance which are very different: in the fields and on the road. To reduce this resistance, there are two possible options which are directly linked to the ground you drive on.

Here are some explanations as to how to optimise rolling resistance and as such improve your profitability…

1. How to reduce rolling resistance in the fields

Your agricultural tractor has to produce tractive force to pull your implements. This effort is directly linked to your engine power and the quality of the link between the tyre and the ground.

Rolling resistance is associated with the tyre/soil link, with several parameters to be taken into account:

- The type of soil and its level of humidity.

- The force transmitted to the ground, linked to the mass of your tractor and implements.

- Your tractor’s grip which slows down movement.

- The slippage necessary if this is not excessive.

What is rolling resistance?

Rolling resistance is the resistance to the force your tractor has to develop to make its tyres move on a given ground.

This resistance is directly proportional to the weight exerted on all the wheels of your trailer, whether these are drive wheels or not.

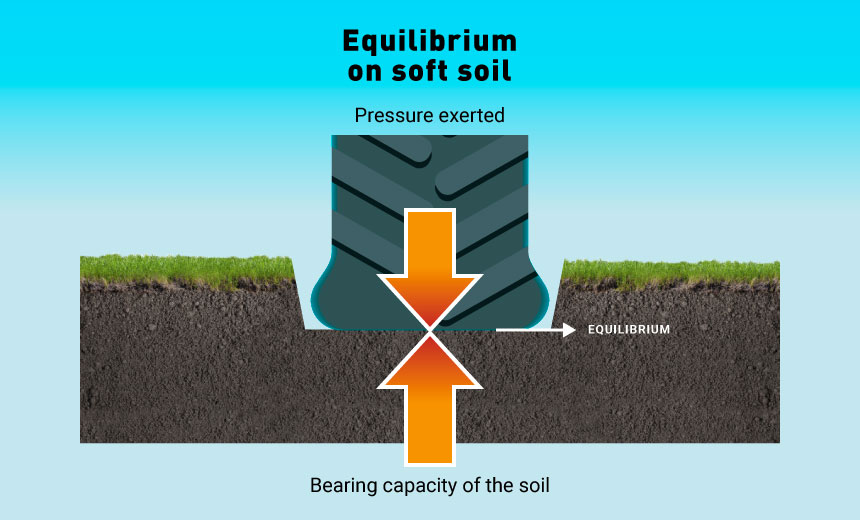

When your tractor is immobile, its mass exerts a vertical force which is met by the force generated by the reaction of the ground. As the tyre and the ground are deformable, the tyre squashes while the soil compacts, until both opposing forces balance out. The tyre’s rolling resistance therefore results from these two squashing movements.

Sinking of the ground under the pressure exerted

Sinking of the ground under the pressure exerted

For an agricultural vehicle, the deformation of the tyre which sinks into the ground constitutes a perpetual obstacle which significantly hinders its movement.

What are the causes of rolling resistance?

1. YOUR TOOLS ARE HEAVY

With heavy tools you compensate for the weight by increasing your tractor tyre inflation pressure, but excess pressure increases rolling resistance as well as the pressure exerted on the soil, leading to its compaction.

When driving in the fields, you have to reduce pressure to avoid excessive slip and soil compaction. In principle, we tend to increase tyre pressure when the weight of the vehicle and its trailer leads to excessive squashing of the tyres. Yet overinflation is often the cause of several counterproductive phenomena when the ground is soft or humid:

- Overinflation: by sinking further into the ground, an overinflated tyre will increase rolling resistance, the quantity of earth in front of the tyre is greater and more effort is required to move forward, given that globally, 1 cm of additional depth leads to 10% more fuel consumption.

- Too much slippage: an overinflated tyre has less grip in the fields and a reduced footprint. The lugs effectively do not have a large enough contact patch which may lead to excessive slippage that will end up causing compaction which will block rain water infiltration and aeration and which will therefore prevent productive root development. When you overinflate your tyres, you increase your slip rate, in particular in humid conditions. We recall that a slippage rate of 30% leads to up to 20% more fuel consumption. You should therefore work with the lowest possible inflation pressure (0.8 bar) to reduce the rolling resistance and the slippage rate.

Comparison of the same tyre in the same conditions;

Comparison of the same tyre in the same conditions;

it does not slip at 1 bar but it slips at a pressure of 1.25 bar

2. IF THE SOIL IS TOO HUMID

With very wet soil, the tyre will sink into the ground until it meets resistance at depth.

- Soil compaction: the soil and the tyre are both deformable elements. When the tyre is inflated to a high pressure, it squashes less but sinks in deeper into the ground, above all in wet conditions or if the soil is loose, leading to excessive compaction and greater rolling resistance.

3. OTHER CAUSES

Other less obvious causes may lead to rolling resistance, such as:

- The friction linked to the wheel hubs’ rotational torque.

- The front axle geometry.

- The drivetrain parallelism, including trailers with two or three axles.

- Transmission elements with pulled implements.

- Ill-adapted engine speed, or excessive travel speed.

How do you reduce rolling resistance in the fields?

When rolling resistance in the fields is too high, you may not realise it, but you will be working continually in a higher gear in order to develop the power necessary to counter this resistance.

This inevitably leads to extra fuel consumption.

Over a full season this represents very high recurrent expenses that you have the possibility of reducing. Here’s how:

Increase the width of the wheels

Increasing the width of the section to a series 75, 70, 65 or 60 dimension wheel is the best solution, as by increasing the width of the tyre you reduce the extent to which it sinks into the ground by increasing the tyre footprint and contact patch with the ground.

The more the tyre remains on the surface without sinking into the ground, the more you reduce your rolling resistance. Increasing the tyre footprint makes it possible to go from vertical compaction to a somewhat lesser longitudinal, transversal compaction.

Use of low-pressure VF tyres

The use of low-pressure agricultural tyres with VF (Very Flexible) technology. These are top-of-the-range tyres with reinforced casing and a sidewall that is more supple and more resistant. They are designed to work at very low pressure, at an inflation pressure as low as below 0.8 bar.

VF tyres offer better overall productivity because they reduce rolling resistance on wet ground. You will slip less and your tractor will need to develop less power for an equivalent task. You will therefore save on fuel.

VF technology was developed to preserve your soils. Thanks to a wider footprint, the mass of the agricultural vehicle is better spread over the ground, reducing the compaction linked to repeated passages over your entire plot of land.

2. Rolling resistance on the road

Here are two examples to better understand rolling resistance on a hard surface:

Example 1

The steel wheel of a railway wagon on a rail track faces almost no rolling resistance, because neither of the two elements undergoes any deformation, whatever the weight of the wagon. The tractive force necessary to move the wagon is therefore minimal.

Example 2

Now let’s take the case of your car with 4 flat tyres in your garage. It would require a considerable tractive force to move it, whereas you would have been able to push it by hand if the tyres had been properly inflated.

These simple examples show us that rolling resistance increases with the deformation of one of the two elements, either the tyre or the ground, or both at the same time.

Unlike earth, the bitumen on the road does not compact due to the weight of your trailer. The only element which adapts is your tyre, which is more or less squashed based on the weight that it bears.

Rolling resistance on the road is defined as the friction between your agricultural tyres and the road surface on which you are driving. Under the weight of the vehicle, the tyre deforms, in particular at the level of its contact area with the bitumen. This deformation increases the contact patch and generates resistance to the tractor’s movement.

On the road, the effect produced is opposite to the effect in the fields due to the nature of the ground. So instead of reducing tyre pressure, it is advisable to increase it to reduce rolling resistance and improve the tractor’s stability. A slight overinflation on the road makes it possible to decrease fuel consumption and wear to your agricultural tyres.

What are the benefits of reducing rolling resistance?

To optimise rolling resistance, it is necessary to adapt the pressure in your tyres to each type of ground on which you drive.

Reducing the rolling resistance of your tyres allows your tractor to use less energy and to reduce fuel consumption.

Less slippage in the fields and less resistance on the road

The lowest pressure possible, with large dimension VF tyres, allows the tyres to stay on the surface and avoid sinking into the ground, reducing rolling resistance by as much.

As soon as you go back on the road, you must increase the pressure in your tyres to up to at least 2 bar to reduce rolling resistance. With this pressure, the contact patch and area of friction with the ground is reduced and you don’t need to accelerate too much to obtain traction.

Better traction

By reducing rolling resistance in the fields, your tractor will have better traction, because the slippage rate is reduced. Grip is optimised since the tyre has a bigger footprint on the ground, the tyre lugs having a larger contact patch.

Time saving

Excess slip in the fields already represents a considerable loss of time and therefore a loss of profitability. In the case of soil compaction, decompaction work is necessary to restore the damaged soil which also requires time and energy.

To spare you all these inconveniences, think about reducing the rolling resistance of your tyres by opting for top-of-the-range VF technology tyres. Their reinforced structure makes it possible to bear heavier loads in the fields and on the road without having to increase inflation pressure.

In short, reducing rolling resistance leads to better profitability, whether at the level of production or at the level of fuel consumption.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc…

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *