Contrary to common belief, adjusting the pressure in your agricultural tyres is an essential point, which can have a significant impact on how well your tyre equipment works and therefore, more generally, on the profitability of your farm.

Incorrect pressure settings can lead to premature tyre wear, excessive fuel consumption and a drop in productivity. In the long run, these factors can turn out to be costly for your farm. In this article, we look at 11 important points that you should know in order to understand and manage the inflation pressure of your agricultural tyres better.

Our objective is to help you optimise the efficiency of your equipment, with the aim of making significant savings and contributing towards an increase in the profitability of your farm.

1. How much does it cost if you don’t adjust agricultural tyre pressure settings?

In general, tyres represent the second most costly item on the budget after your tractor’s fuel. Choosing not to manage your agricultural tyre pressure settings correctly can lead to premature wear, excess fuel consumption and a drop in productivity.

It is therefore essential to check the pressure in your tyres regularly and adjust it depending on your load and working speed.

What is the impact of underinflated tyres on the road?

With speed, the rubber in the tyre heats up which makes it more sensitive to abrasion from the hard road surface.

If you drive frequently on the road with pressure that is too low, there will be too much deflection which is not counterbalanced by the inflation pressure, stability when cornering and braking will be insufficient and the rate of wear will increase rapidly. On average, the lifespan of your tyres will be reduced by 25%.

What is the impact of overinflated tyres in the fields?

With too much inflation pressure, the tyre will sink further into the ground.

Each additional centimetre of extra depth increases fuel consumption by 10%.

With high pressure, the lug contact patch with the ground is reduced, traction is less efficient and there will be more slip.

As you generally spend more time in the fields with your tractor than on the road, the impact on wear will be directly linked to this time ratio, again leading to a reduction in the tyre’s wear life.

2. Understanding the link between pressure, load and speed for your agricultural tyres

The pressure in your agricultural tyres is directly linked to the load that they have to carry and the speed at which you intend to work.

The three parameters are linked and you can modify one or other of them depending on your work priorities.

If you give priority to load, you must reduce speed to avoid having to increase the pressure too much

You want to use large implements, which will be heavier, to cover a larger surface area for example. To avoid having to increase pressure too much and to avoid excessive soil compaction, you will need to reduce speed considerably.

If your priority is speed, to travel by road for example, you must increase pressure

High speed places the tyre under strain, so you will need to increase pressure to reduce the tyre’s contact patch with the road and thus limit rolling resistance. It is also preferable to reduce the load for the same reasons.

If your priority is working with a low inflation pressure

To protect your land which is your main asset and avoid soil compaction, you can choose to work at low pressure. To limit the strain linked to load, you must imperatively reduce your speed.

3. What is the right pressure for any tractor tyre?

The ideal pressure for a tractor tyre does not correspond to a specific setting, but depends on several factors, such as the type of soil, the activity to be carried out, the load, the working speed and the tyre technology.

In general, the pressure must be sufficiently high to bear the load without placing undue strain on the tyre casing, but sufficiently low to allow good traction and minimise soil compaction when working in the fields.

your agricultural tyre pressure regularly

The right pressure depends on the load

Pressure counters the effect of the load, and must therefore be established on the basis of the weight of your implement. You will find the optimal load index recommended by the manufacturer for a given speed marked on the tyre’s sidewall.

You will then be able to vary pressure, having opted either for a reduction in speed or in load.

The more often you work at the right pressure based on your load, the longer you will make your tyres last over time.

4. Basic advice for better management of agricultural tyre pressure

- Before adjusting your pressure settings, it is necessary to determine your tractor mass and the weight the different implements used as well as any related load transfer. Adjustments will then be easier and better adapted to your actual equipment.

- Get into the habit of adapting the pressure of your agricultural tyres. It is advisable to check the inflation pressure regularly and adapt it as often as possible based on your load and working speed.

- Have a TPMS installed to keep a constant eye on pressure from the tractor cab and ensure that you are always at the right level.

- If you are aiming for optimal pressure adjustments, a central tyre inflation system is ideal.

- Choose tyres that are adapted to your working conditions, with the right technology, such as low-pressure VF tyres for example, for use mainly in the fields. This very judicious choice will lead to significant savings in the long run.

5. Can you exceed the recommended pressure for tractor tyres?

It is generally not advisable to go beyond the recommended pressure in your tractor tyres. Too much pressure can lead to premature wear.

However, it is possible in some cases and can be very useful.

coming off the rim on sloping land

In which cases can it be beneficial to exceed the recommended pressure?

It is important to note that going beyond the pressure set by the manufacturer is only advisable when it’s very dry and the ground is not wet.

The ground’s bearing capacity must be optimal to cope with the higher pressure without this resulting in compaction.

This rule is valid for all the examples below:

- You can equip your tractor with a heavier implement to cover a wider area by increasing the pressure to a little over the manufacturer’s recommendations.

- If you equip your tractor with a front loader, it will be wise to increase pressure to compensate for the load transfer to the front axle.

- On very sloping land, higher pressure can be a good solution to avoid coming off the rim.

- During the harvest, high-tech tyres that can cope with cyclic loads can have their inflation pressure increased so that you can work continuously, even if the hopper is filling up.

6. What tyre should you choose to have the same pressure on the road and in the fields?

If you are not equipped with an additional compressor, it won’t be possible to increase pressure before moving onto the road, after having worked at low pressure in your field.

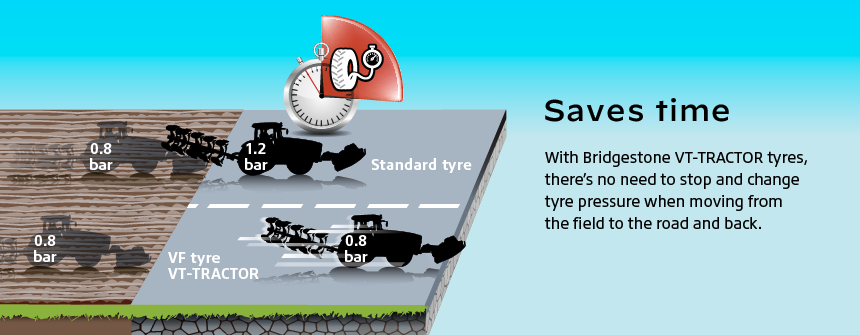

Low-pressure VF tyre technology allows you to drive on the road at a pressure of 0.8 bar on a non-recurring basis, without damaging the tyre casing which has been designed for this type of use (of course while respecting the manufacturer’s load/pressure data).

This technology minimises wear and fuel consumption while maximising productivity.

you no longer have to increase pressure on the road

7. The keys to working at a very low inflation pressure with your agricultural tyres

Working at a very low inflation pressure with your agricultural tyres will help you improve your yields. An average pressure of 0.8 bar will effectively allow you to minimise soil compaction, improve traction and reduce fuel consumption, leading to real savings into the bargain.

However, it is important to work with tyres that were designed for this use, because if you reduce pressure too much in standard tyres thy will not be able to withstand the load which will ruin your tyres rapidly.

8. Advantages of low pressure tyres compared to standard agricultural tyres

Low-pressure VF tyres are designed to boost tractor capacity. Where standard tyres don’t have the resistance or suppleness necessary to cope with heavy strain and generally need to maintain an inflation pressure above 1.2 bar (reference pressure which takes into account load and speed factors corresponding to size).

VF tyres have been engineered with a high-resistance casing and can work without any problems at very low pressure. The sidewalls have been redesigned to offer much more flexibility without compromising their solidity or resistance capacities.

In addition to working at low pressure, VF tyres have:

- A higher load capacity

- A larger footprint to protect your soil

- Better traction and less slip

- The possibility of changing ground without adjusting pressure

- Greater safety during braking on the road

- Better driving comfort without vibrations.

9. Use tyre pressure monitoring or a complete remote inflation system

The choice between tyre pressure monitoring and a complete central tyre inflation system depends on your needs and on your budget. Both systems allow you to manage pressure with the possibility of reducing wear and fuel consumption.

A complete CTIS is ideal because it allows you to adjust tyre pressure directly from the tractor cab based on your working conditions. This permanent adjustment capacity means that you can always work with the best grip and traction capacity possible. Productivity is improved and the wear life of your tyres increases significantly.

perfect management of agricultural tyre pressure

10. Opt for a harvest campaign with low-pressure tyres

The use of low-pressure tyres during a harvesting campaign can help minimise soil compaction, improve traction and reduce fuel consumption. Bridgestone’s VT Combine CFO tyres allow you to work at low pressure despite the heavy load.

They have been designed to cope with cyclic loads and can work at between 1.2 bar and 2.4 bar. The larger soil footprint spreads the pressure more evenly over a larger contact patch with the ground.

compared to standard tyres with the same load

11. Tank Air Wheels, to increase inflation pressure in 1 minut

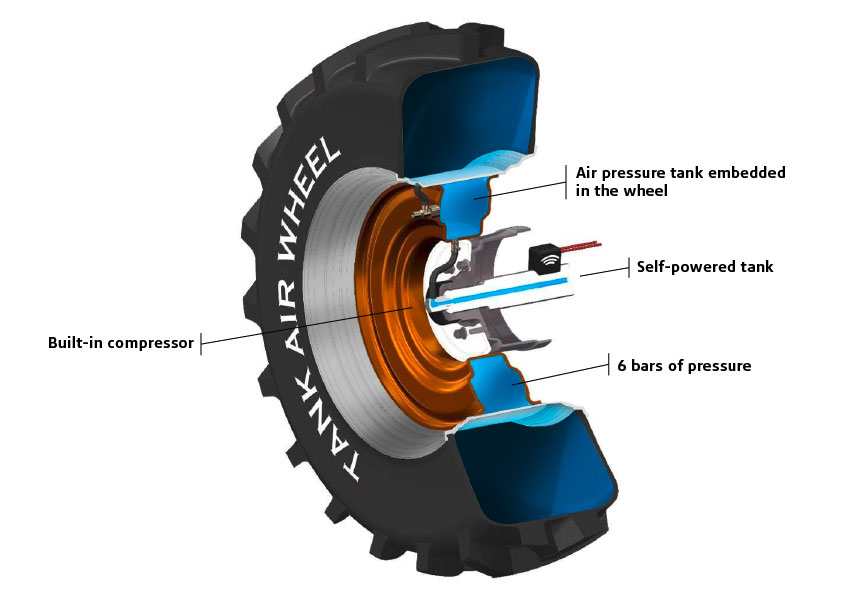

Tank Air Wheels are a revolutionary system which allows you to increase tyre pressure almost instantly.

The system is particularly useful when you go from road to fields or fields to road. Tank Air Wheels offer an exceptionally fast inflation time thanks to their autonomous, built-in compressor which does not require any further installation on your tractor.

The tank in the wheel rim contains dozens of litres of air at a pressure of 6 bar, which can be injected into the tyre in less than one minute.

CONCLUSION

The management of agricultural tyre pressure is a key element in maximising productivity and extending the wear life of your equipment.

By understanding the link between pressure, load and speed and by choosing the right tyres for your farm, you can optimise the efficiency of your equipment and make significant savings.

Don’t forget that good management of tyre pressure begins by checking your tyres regularly and adjusting the pressure settings based on your working conditions.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice that you need about your farming tyres. They will help you to maximise your productivity with information on all things relating to tyres: inexpensive tractor tyres - technical data for farming tyres - advice on farming tyre pressure - solution to avoid soil compaction - sprayer tyre pressure - Why and how to ballast your tractor tyres - when to use twin wheels - the mechanical causes of abnormal wear - cheap agricultural tyres - etc.

To take it a step further and increase the profitability of your farm, the tractor tyre experts has prepared a free, highly detailed, ebook which explains the essential role of farming tyres on your productivity.

Most people who read this article have also read some of the following articles:

- 12 simple tips to better manage the pressure of your agricultural tyres

- How to get rid of the tractor tyre pressure adjustment step

- Farming tyres, pressure monitoring or full Central Tyre Inflation System CTIS

- 7 advantages of low-pressure tyres compared to normal tyres

- What is the right inflation pressure for any tractor tyre

- The keys to working at very low pressure with your agricultural tyres

- Understanding your tractor tyres’ pressure -load -speed link

- Tank Air Wheel rims, to inflate tyres in 1 minute

- Can you go beyond the recommended pressure for your tractor tyres?

- Opt for a harvest campaign with low-pressure tyres

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *