When it comes to replacing tyres, we tend to think first about wear to the tread or the lugs, but less often about whether the tyre has incurred any damages on other parts which are just as important. The tyre bead is one of these parts because it plays a major role, ensuring that the tyre is airtight on the rim.

Although this zone is particularly well reinforced, with its steel ply which help to make the bead rigid, in certain cases it may become damaged and require replacing, even when the tread is still relatively new.

The bead area is a part of the tyre that cannot be repaired because it is too important in the structure:

- it forms the link to the rim seat. This is the indented part of the rim which connects tyre and rim and enables transmission of torque to the tractor tyre,

- the internal steel bead wire ensures rigidity and cohesion between the tyre and the rim during inflation,

- the bead is a complex assembly of materials put together during the manufacturing process (bead wires, reinforced casing plies as well as different rubber components which will provide rigidity, resistance to heating and abrasiveness). The bead also provides suppleness for the contact area on the rim seat.

In this article we look at the most frequent types of damage to the bead:

1. Rotation of the tyre on the rim

In certain cases, the tyre may slip on the rim during a high tractive effort. This rotation will generate heating at the level of the bead, accelerate wear to the protective rubber and, in extreme situations, lead to shearing of the reinforced casing ply and separation from the tyre bead.

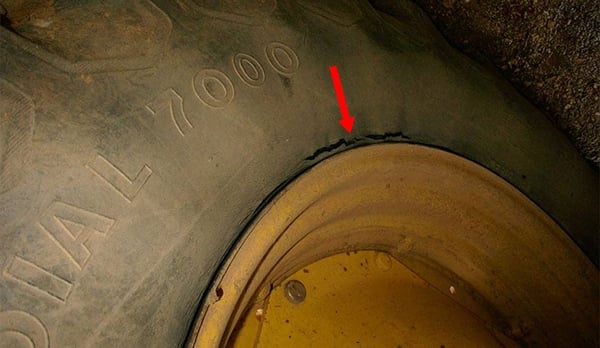

Separation of the bead wire

Separation of the bead wire

This happens essentially in the following two circumstances:

- if the tyre is overloaded or underinflated for long periods during use, the mass crushes the tyre, preventing its rotation on the ground which is transferred to the level of the rim.

- if a large size tyre is mounted on a rim that is too narrow. In this case, under the combined effort of the load and the pressure, the tyre rubs against the edge of the rim. This phenomenon is accentuated if the tyre is underinflated.

As soon as the bead wire becomes visible at the level of the bead, or if the break is just above the bead wire, the tyres will be unusable and will systematically have to be replaced, making sure that the new tyre is suitable for the rim reference.

2. Bead damaged by a rim in bad condition

Mounting a new set of tyres on very old rims is not always a good choice. A very rusty rim, which is often used for example when filling tyres with water, may cause corrosion at the level of the bead.

Bead damaged by the rim

Bead damaged by the rim

If your rims are old or rusty:

- Reconditioning the rims before mounting new tyres may be a good solution.

- Regular cleaning of the rims to avoid the presence of too many foreign bodies (earth, stones, branches…) at the level of the rim/bead junction is highly recommended.

Attention: certain bead models which do not protect the edge of the rim facilitate the accumulation of foreign bodies at the level of the rim/bead junction. It is preferable to avoid this type of tyre.

If the bead is cut, worn or severely damaged, there is a major risk of sudden loss of pressure, resulting in more serious damages.

3. Break at the end of the reinforced ply

When you notice a fissure between the bead and the sidewall, even if it is very slight, it’s often too late. The separation has occurred at the level of the ply turn-ups just above the bead reinforcement.

Tear on the edge of the bead reinforcement

Tear on the edge of the bead reinforcement

This type of tear generally occurs in the following cases:

- If you drive too often with very insufficient inflation pressure on the road. To be able to drive at low pressure on the road and in the fields, it is essential to be equipped with VF technology tyres.

- If you are frequently overloaded for extended periods. The edge of the sidewall is pushed against the edge of the rim which causes the break.

- If the break is at the place where the bead lifter is placed, there has been too much friction in this zone due to repeated mounting and dismounting operations, resulting in a structural weakness.

This type of damage can obviously not be repaired, but when you replace the tyre, it is preferable to choose a higher volume series 70 or 65 tyre to increase the load and of course always check tyre pressure.

4. Bead damaged during mounting

Mounting and dismounting are tricky moments which require experience in this type of operation and proficiency in use of mounting and dismounting equipment, whether the task is done manually or with a machine.

Bead pinched by a machine during mounting

Bead pinched by a machine during mounting

There are several ways that you might damage the bead during mounting:

- The bead positioning tool has moved and caused the bead to tear.

On automatic machines, a bead which is not sufficiently lubricated has trouble getting past the edge of the rim, then may be positioned at a tilting angle on the rim edge, squashing the bead sealing zone. - During manual tyre mounting using several levers. The incorrect positioning of the levers may cause a tear or cut to the bead.

If the bead has been damaged, squashed or pinched during manual mounting or mounting with a machine, you must not try to drive with the tyre. Depending on the problem, there is a real risk of explosion when inflating the tyre or driving.

5. Break in the bead wire

A break in the bead wire generally occurs during inflation at the time of the “water hammer effect”. This is the moment when the pressure is sufficient within the tyre to push the beads into their end position in one go.

Tyre with a broken bead wire

Tyre with a broken bead wire

The bead wire may break for the following reasons:

- If the new tyre was mounted without using grease or if the sides of the bead were not sufficiently lubricated, one of the bead wires may break during the final shock of inflation.

- If the tyre is overinflated or inflated without supervision, a bead which is not positioned correctly will probably cause a bead wire to break.

The inflation process is a critical moment and you should never go beyond a pressure of 2.5 bar when setting beads in place.

If you reach this level of pressure and the beads are not correctly positioned, it is much better to deflate the tyre and find out where the problem is coming from rather than destroy a new tyre or, even worse, cause a serious accident linked to an explosion.

TO CONCLUDE

A new set of tyres requires a certain budget, and it would be a shame to have to replace your new tyres before having been able to use them, just to make savings on tyre mounting.

Turning to a profession whose job it is and whose work is guaranteed could mean avoiding a lot of problems, such as an error in size or alteration of the bead during mounting, meaning that you have to replace your tyres prematurely with all the ensuing economic consequences.

To learn more about ways to increase your farm’s productivity, bridgestone-agriculture has created a comprehensive eBook on the topic which is available for you to download for free:

Bridgestone-agriculture Blog is written and administered by tractor tyre experts who are available to provide you with advice on agricultural tyres. They will help you to maximise your productivity with information on all things relating to tyres: inexpensive tractor tyres, technical data for agricultural tyres, solutions for avoiding soil compaction, sprayer tyre pressure, why and how to ballast your tractor tyres, when to use dual-wheels, the mechanical causes for abnormal wear, discounted agricultural tyres, etc...

Most people who read this article have also read some of the following articles:

- 10 tips to reduce abnormal wear to your farming tyres

- Agricultural tyres: +37% wear due to misalignment

- The worst consequences linked to used tractor tyres on your soils

- Why do my front tractor tyres wear much quicker?

- How to limit agricultural tyre wear faced with heavy loads

- When does a split make it necessary to replace your tractor tyres?

- Repairing tractor tyres: the techniques for each situation

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *