The use of power is not always compatible with soil preservation, even if there are numerous types of tyre on the market: radial tyres, high volume tyres or very high flexion (VF) tyres.

These technologies allow you to work at low pressure; but wouldn’t dual wheels enable you to go further?

Dual mounting is an excellent option for powerful tractors while avoiding soil compaction caused by tyres, this is why:

You surely know that to COMBAT SOIL COMPACTION you must use low pressure tyres

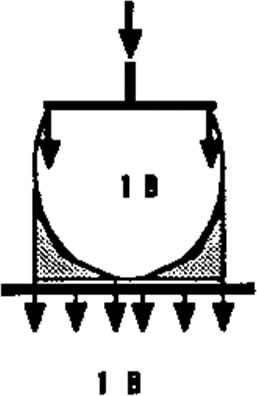

Soil compaction is linked essentially to inflation pressure. In theory, for a given working pressure, it therefore does not depend on the load.

An increase in the load borne by the tyre will lead to a greater deformation of the tyre. The contact surface with the ground is then bigger and the load is spread out better. The pressure to the ground therefore remains constant. But what advantages does dual mounting bring?

In what cases do dual tyres really improve your productivity?

When your car has a heavy load, you are advised to increase your tyre’ inflation pressure. The same goes for agricultural tyres.

However, when you use a powerful tractor (which is therefore relatively heavy) with very wide implements (which are also heavy) and you wish to continue working at low pressure, the tyres already used are not enough. The solution is therefore to decrease the load to the ground by spreading it over several dual tyres.

There are two main benefits to dual mounting:

1st benefits

On the one hand, it offers a better distribution of weight on the ground with lower operating pressure, which is indispensable for limiting compaction. The images below show the increase in the contact surface with the ground with dual tyres (right footprint) compared to with a single tyre (left footprint).

2nd benefits

On the other hand, it increases your tractive force considerably and reduces slippage ((the solution to ruts) thanks to a higher number of lugs in contact with the ground and an increase in the rolling surface in contact with the ground.

This preserves the structure of your soil and helps you improve productivity, working time and efficiency considerably (see article “+20% extra fuel consumption linked to tractor tyre slip”).

4 techniques for successful dual mounting

In principle, dual mounting is a simple way of combating crop compaction. However, its implementation is sometimes complex. There are effectively many configurations possible and it isn’t always obvious choosing which is the most suitable option.

The possible configurations differ on the basis of size and distance between wheels in order to adapt to different work and crops.

Here are four possibilities:

1. Using same-size wheels

The simplest configuration for dual wheels involves using two wheels of the same size. The disadvantage is that your vehicle may become quite wide, especially if the dimension of the tyres alone represents considerable width, and this may limit your circulation by road.

2. Wide wheels for multiple purposes

To limit the width of your tractor, wide tyres may be used together with narrow tyres (see below). This configuration is more complex to set up and use because the different tyres do not behave in the same way.

3. Narrow wheels for hoeing

4. Double furrow wheels

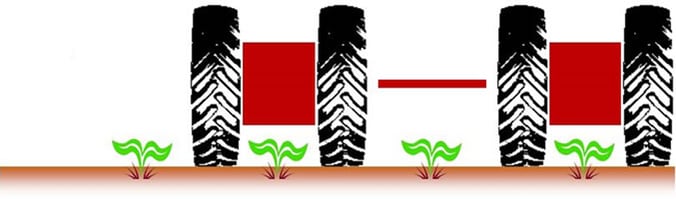

Lastly, double furrow agricultural wheels may be used to preserve your soil without damaging crops in rows (corn, beetroot or market gardening crops, for example).

What type of tractor tyre should I choose?

Once the configuration has been decided, all that’s left is to choose good tyres. Here again, the choice is not necessarily easy.

First of all, dual tyres must be the same type of tyre. If your tractor is equipped with radial tyres for example, you will also need to use radial tyres for the dual mounting.

In certain configurations (same-size wheels or double-furrow wheels), identical wheels can be chosen. This is the most simple and efficient option because the two wheels have the same width and the same profile and react in the same way.

On the other hand, if you opt for different tyres, the difficulty will be having the same reaction for each tyre. For this, pay attention to their deformation as a result of the load (wheel more or less squashed) and to the operating inflation pressure. Inflation pressures may often be different for optimal use.

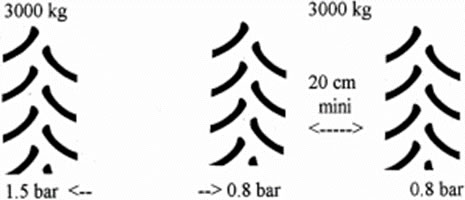

Lastly, choose a suitable dual mounting set-up. The space between wheels must be wide enough to allow the evacuation of earth between the tyres and to allow the deformation of the tyre under the weight of the load without there being any contact between the two sidewalls. The minimum width is 20 cm and depends on the type of agricultural tyre used. With flexible tyres in particular, more space is required between the wheels.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Technical data for agricultural tyres – Agricultural tyre performance – Air pressure advice – Solutions to avoid soil compaction – Sprayer tyre pressure – Why and how to ballast your tractor tyres – etc….

To take it one step further and increase the profitability of your farm, les Experts du pneu provide a free, highly detailed eBook which explains the essential role of the agricultural tyre in your productivity.

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *