Slippage, compaction or the formation of ruts are often the result of a bad choice of agricultural tyre or the wrong adjustment of the tyres which is not always easy to detect.

A close look at your tractor tyre footprint can help you to easily diagnose the use of unsuitable equipment, badly adjusted settings or excessive wear.

Look at the agricultural tyre footprint in the sand or in the fields

You can study the tyre footprint in the fields if the conditions are right (dry ground) but it is best to use a sand track. Sand improves observation conditions and allows for homogenous testing conditions (state of the soil, humidity) which makes the measurements easier to reproduce. You can therefore compare footprints from different tyres with different inflation pressure and/or variable loads.

Tyre footprint using a sand track

Compare footprints in different operating conditions

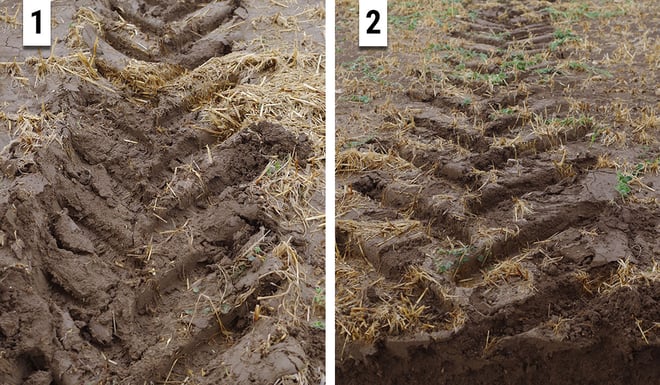

The example below shows the footprints of 2 tractors equipped differently.

The left footprint (1) corresponds to a 270 cm tractor tyre with an operating pressure of 3 kg/cm² (i.e. around 3 bars), it is narrow, deep and not very clearly defined. The excessive soil compaction will lead to a progressive degradation of the ground and a considerable loss in productivity in the long-term.

The right footprint (2) corresponds to a 650 cm tractor tyre with an operating pressure of 1 kg/cm² (i.e. around 1 bar), it is wider, much less deep and very clearly defined because the pressure applied to the ground is lower and more evenly spread out. The soil beneath this footprint will be better preserved and the plants’ root systems will not undergo any excessive pressure. Productivity and profitability in this case will be greater.

Evaluate the surface of the footprint

Several parameters can be assessed thanks to the footprints. Firstly, the surface of the footprint determines the spread of pressure. The larger the footprint, the lower the risk of soil compaction.

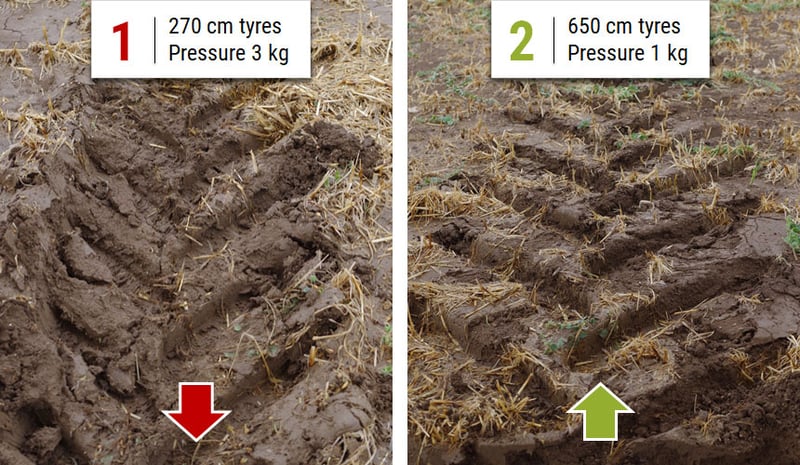

The footprint is characterised by the surface of the lugs which come into contact with the ground and varies depending on the operating pressure (see photo below): the lower the pressure, the larger the footprint. By measuring the width of the footprint and comparing against the width of your tyres with no load (provided by the manufacturer), you will be able to assess tyre deformation.

Variation of the tyre footprint depending on pressure

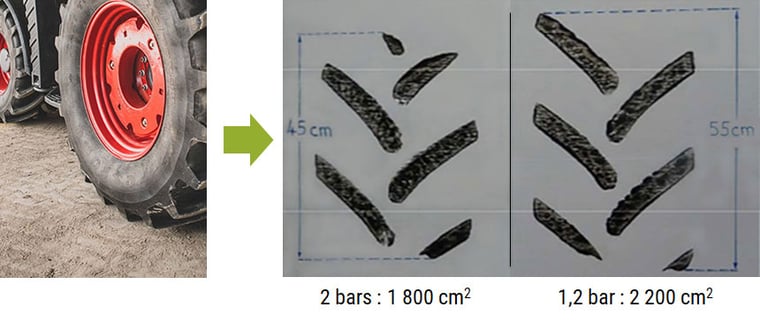

Evaluate the depth of a rut

Another measurable parameter is the depth of a rut, which is how far the agricultural tyre has sunk into the ground. In the example cited above, the rut is deeper with narrower tyres with a high inflation pressure than with wide tyres with a low inflation pressure.

Comparison of ruts formed by two different tyres

On the left: deep rut

On the right: shallow rut (barely visible

The rut must be as shallow and as even as possible, showing that the load is spread evenly. If the depth of the footprint is not even over the length of the tread, this can be a sign of severe wear or bad alignment of the tyres (camber problem).

Evaluate the quality of the footprint

Lastly, look carefully at the clarity of the footprint. If the contour of the lugs is not clearly defined, your tractor probably has a high slip ratio. Check the wear and the pressure of your tyres.

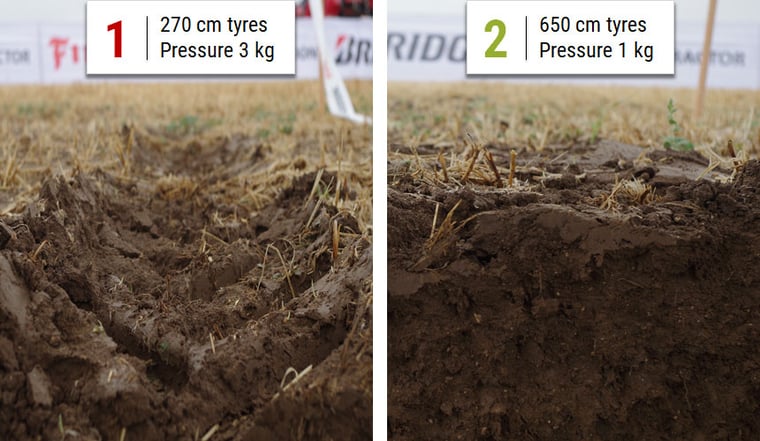

Evaluate the in-depth impact on the soil

You can also observe the in-depth impact of the passage of agricultural machinery by examining the trenches that have been dug into the ground. Soil profiling must then be carried out. For low soil compaction, the structure of the soil must remain crumbly after the passage of the wheels. The state of compaction can be determined before and after the tractor has passed thanks to a penetrometer in order to assess the impact of the tyres on the soil at different depths and the extent of compaction generated (surface soil compaction and/or deep soil compaction).

Soil profile

Carry out an in-depth diagnosis using specific measurement tools

If you have identified problems, plates equipped with pressure captors may be supplied by the manufacturers. They allow you to determine more precisely the footprint and the distribution of pressure. A more detailed diagnosis is thus established to enable you to adapt your tyres to your use and preserve the potential of your soil.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Technical data for agricultural tyres – Agricultural tyre performance – Air pressure advice – Solutions to avoid soil compaction – Sprayer tyre pressure – Why and how to ballast your tractor tyres – etc…

To take it one step further and increase the profitability of your farm, les Experts du pneu provide a free, highly detailed eBook which explains the essential role of the agricultural tyre in your productivity..

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *