You work with very powerful machines equipped with heavy implements and you would like to improve your productivity while preserving your soil from compaction, to guarantee future yields.

With standard tyres you are obliged to increase tyre inflation considerably to compensate for load, making these tyres incompatible with your soil preservation objectives.

You have two remaining options, between doubling up your current tyres or choosing VF technology low-pressure tyres. Each of these two solutions will make a great difference; you will improve traction, save time by reducing slip and preserve your soil against compaction.

Yet each solution has its pros and cons which we discuss here for you in this article to help you make the best choice for your farm:

You regularly work in very large fields and optimising your productivity is a crucial factor for your profitability. You are therefore particularly interested by a choice of tyre that will give you the best return on your investment and the decision as to whether to opt for duals or low-pressure tyres is crucial.

In both cases your productivity and soil preservation will improve considerably, but to simplify the choice here are the benefits and drawbacks of duals and low-pressure tyres:

1. What are the benefits of duals?

Better distribution of weight to the ground

There is a simple point of reference to know if your tyres cause soil compaction. In general, the pressure within your tyres corresponds to the pressure exerted on the ground.

If you inflate your tyres to 1.5 bar to compensate for a load of 3000 kg on each rear tyre, by using the same size duals you can halve the inflation pressure to carry the same load, i.e. 0.8 bar for each dual to carry these 3000 kg.

In addition, if you use low-pressure tyres as duals, the load capacity can be increased by 75% of the initial capacity, which means that you could bear 5250 kg at 1.5 bar, travelling at the same speed.

Better distribution of weight to the ground with duals

Better distribution of weight to the ground with duals

Obtain better traction

If you work with wide, heavy implements and you wish to improve your productivity, duals are a very good way of increasing your tractor’s traction capacity.

With four rear tyres, you will have more lugs in contact with the soil, giving you twice as much grip on the ground which will reduce slip considerably, even in wet conditions.

2. What are the disadvantages of duals?

Problem of size on the road

The simplest set-up is to add an extra wheel which is the same size as your current tractor wheel. However, this means that the tractor’s ground footprint is excessively wide, which can cause traffic problems on the road.

Travel by road may become troublesome due to the width of the dual tyres (often over 3.5 metres) and the narrow roads used.

If you choose to combine narrow duals with wide tyres to avoid making the tractor too wide, you may find it harder to adapt the equipment overall, because tyres of different dimensions will not behave in the same way, will not have the same inflation or the same flexion capacity when loaded, leading to other drawbacks.

Difficult travel by road due to the width of a tractor with duals

Difficult travel by road due to the width of a tractor with duals

Complex equipment to set up

Adding a set of duals takes time and mounting/dismounting operations cannot be done on a regular basis as this would be far too time consuming.

The tractor needs to stay in the same configuration for a long period of time, so it must be able to work continuously in large fields to optimise profitability.

Not always efficient for avoiding compaction

Duals are generally used only at the rear of the tractor, which is perfect for improving traction and reducing pressure on the rear axle.

However, leaving single tyres on the front axle leads to soil packing and compaction linked to the front axle, especially if you have correctly split the weight by adding ballast to the front to obtain a 40% load on the front axle.

2. What are the benefits of a low-pressure VF agricultural tyre?

VF tyres limit soil compaction

VF for Very high Flexion indicates that the tyres are high-tech and can work at a very low inflation pressure: 0.6 bar at low speed or 0.8 bar at normal speed. The technology used in the production of these tyres enables the very supple sidewalls to flatten without altering the tyre’s internal structure. The soil footprint expands, and the weight is spread over a larger contact patch with the ground.

You can see from the tests below that despite the use of a very powerful 320 hp John Deere 8320 tractor, there is no in-depth soil structure modification with VF VT-TRACTOR tyres with an inflation pressure of 0.8 bar.

The earth strata remain horizontal and keep their friable aspect, which allows for good water filtration in the deep layers and preservation of biological life that is essential for optimal crop cultivation.

TEST 1: Carried out with a 320 hp John Deere 8320 tractor

TEST 1: Carried out with a 320 hp John Deere 8320 tractor

with high volume VF 800/70 R38 VT-TRACTOR tyres

at an inflation pressure of 0.8 bar

TEST 2: Carried out with a 190 hp John Deere 6190 tractor

TEST 2: Carried out with a 190 hp John Deere 6190 tractor

with narrow 300/95 R52 Performer 95 tyres

at an inflation pressure of 4 bar

Increased load capacity

At the same speed and with the same inflation pressure, a low-pressure VF tyre can bear 40% more load than a normal tyre.

It is therefore ideal for working with larger, heavier implements, to reduce the number of passages across the land, or limit the number of road trips back and forth during harvesting, for example.

Time saving

More practical to implement than duals, low-pressure VF tyres can be used continuously throughout the year and have no impact on the width of your tractor.

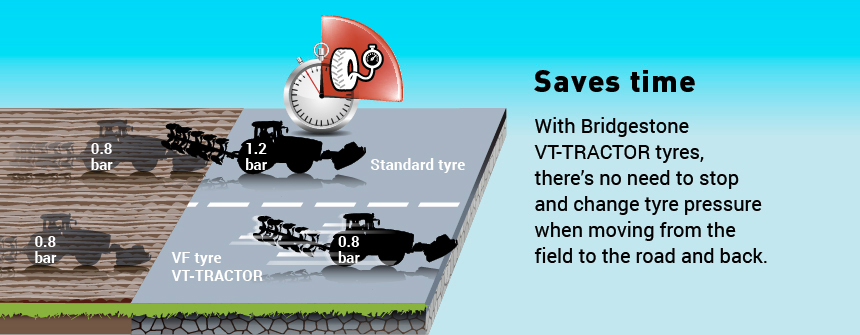

Thanks to its superior technology, the VT TRACTOR tyre saves you from having to adjust inflation pressure between the road and the fields.

Time saving: with Bridgestone’s VT-TRACTOR tyres

Time saving: with Bridgestone’s VT-TRACTOR tyres

3. What are the drawbacks to low-pressure VF tyres?

High budget

Investing in low-pressure VF tyres requires a much higher budget than for a discount tyre, but the return on investment is good.

Productivity is above average, with better traction and less slip which means that you save time and fuel, as well as limiting soil compaction to preserve future yields.

Less traction and load for small tyres

If you do not use large size VF tyres, you are limited in terms of load and traction compared to duals…

Conclusion

The choice will depend on your farm set-up.

- For very large areas, duals will be more productive because you will be able to keep them most of the time, and as traction is better, you will save time over the distance.

- For a more versatile use of the tractor for cropping as well as transport by road or other activities, the low-pressure VF tyre is more adaptable, easier to use, with no problems on the road, but with the same benefits as duals in terms of traction and soil preservation.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc.

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles:

- 5 essential techniques to optimise your agricultural tyres

- How your tractor tyres affect your fuel expenses

- Why your tyres’ speed index is primordial

- Increase the volume of your tyres to boost your tractor

- Why is the rolling resistance of tractor tyres a problem?

- Are my agricultural tyres suitable for use on the road?

- Which agricultural tyres are most suitable for working on sloping land

- How to maximise traction with my tractor tyres

- Agricultural contracting companies: improve team awareness about tyres

- Equipment sharing cooperatives: How to manage the agricultural tyre budget?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *