Low-pressure tyres have evolved over time to become even more high-performance. These developments mean that you can now work at an even lower inflation pressure or carry even heavier loads. These high-tech tyres which belong to the third generation of VF tyres offer exceptional soil preservation qualities despite the load.

The evolution of VF tyres has made it possible to work with bigger, heavier implements, covering a greater surface area with less passages across the land while preserving the soil, thus preserving the future yield capacity of the land.

In this article we look at the major developments in the three generations of low-pressure tyres.

1. IF tyres mark the 1st generation of low-pressure tyres

The overall trend is towards a reduction in manual labour on farms, which has been countered by more machines, bigger or wider implements and tractors that are more powerful and much heavier.

Unfortunately, while the weight of the machines increases, the soil does not change and cannot cope with the repeated compaction without consequences in terms of future yields.

To mitigate this problem, the evolution has come from tyre technology, with the development of the IF tyre to take account of this extra weight.

This technology opened up new possibilities; while the tyre could allow you to carry more load, it also meant that with the same load you could work at a lower inflation pressure to preserve your soil.

to improve productivity

The first tyre able to work at low pressure without speed limitations was the IF (Improved Flexion) tyre

It has a reinforced casing and more resistant, yet supple sidewalls which allow it to operate at a pressure of as low as 0.8 bar.

This ensures optimal working pressure to preserve your soil. This tyre technology provides an excellent grip on the ground thanks to its larger footprint and the special design used for the structure of its tread.

As opposed to a standard tyre, you no longer need to change the pressure in an IF tyre when going from road to field.

Thanks to its reinforced sidewalls, this agricultural tyre can be used on all types of terrain with the same pressure and a wide speed range, so that you don’t have to get down from your tractor cab any more when you go from one type of ground to another to adjust the pressure settings. In addition to a working speed and transport speed which can be increased, this represents considerable time savings at the end of a working day.

The IF technology tyre is capable of bearing up to 20% more load than a standard tyre. This is due in particular to the quality of the materials used in the production of the casing and the structure of the tyre.

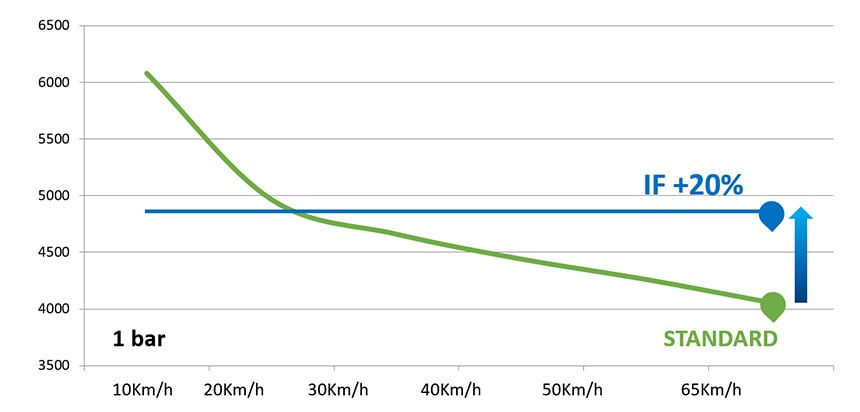

Comparison of the load and speed capacities

of a standard tyre and an IF tyre at a pressure of 1 bar

An example of load in identical conditions

Here is the comparison between an IF 710/70 R42 tyre and a standard tyre of the same size:

- IF tyre: maximum load 4,890 kg with a pressure of 1 bar and a speed of 65 km/h,

- Standard tyre: maximum load of 4,055 kg again at 1 bar and with a speed of 65 km/h,

i.e. a difference of 835 kg in favour of the IF tyre.

2. The VF tyre represents the 2nd generation of low-pressure tyres

The VF (Very High Flexion) tyre has a more innovative design.

It is made from better quality materials and a high-tech process is used for the assembly of its casing, making it extremely robust.

Its more resistant, more supple sidewalls give it an extensive flexion capacity.

It is more efficient than the IF tyre and can carry up to 40% more load than a standard tyre thanks to this reinforced structure casing.

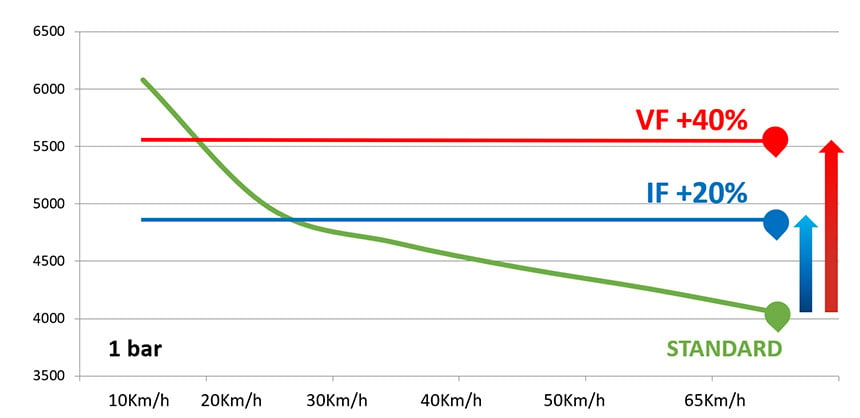

Comparison of the load and speed capacities

of an IF tyre and a VF tyre at a pressure of 1 bar

An example of load in identical conditions

Here is the comparison between a VF 710/70 R42 tyre and a standard tyre of the same size:

- VF tyre: maximum load 5,600 kg with a pressure of 1 bar and a speed of 65 km/h,

- Standard tyre: maximum load of 4,055 kg again at 1 bar and with a speed of 65 km/h,

i.e. a difference of 1,545 kg in favour of the VF tyre.

Ideal for soil preservation

VF tyres are designed to work at low pressure which makes it possible to avoid excess soil compaction and preserve the soil’s fertility and the future yields in your fields.

These high-tech tyres have a bigger and above all longer soil footprint, which spreads out the pressure exerted on the ground better.

Time saving

VF tyres can maintain the low inflation pressure of 0.8 bar in the fields and on the road, whereas a classical agricultural tyre cannot go below 1.2 on the road if you wish to drive at a normal speed.

This is an enormous advantage in terms of reducing working time if you have several fields to work on in the same day that are some distance apart.

Reducing the amount of slip

In addition to soil compaction, tyre slippage is a factor that can be problematic in the fields in wet conditions.

This can be managed thanks to use of VF agricultural tyres like the VT-TRACTOR just by reducing inflation pressure to 1 bar or 0.8 bar when working in the fields.

and the right tyre which is slipping at 1.25 bar in the same field

The lugs have a specific design, with multiple, curved angles, designed to facilitate traction and avoid earth accumulating between them.

This ingenious lug design reduces the slip rate of a VF tyre. Traction is improved, work completed quicker and there is less wear over time.

3. The new generation of VF tyres which boosts the low-pressure capacities

The new generation VF tyre takes us even further, the load bonus increases even more at low speed just like with an ordinary tyre, but with the VF capacities.

These allow even more load without ever compacting the soil thanks to their supple yet resistant casing. They effectively have a large contact patch with the ground which allows the weight of the tractor to be spread over a bigger surface area.

More load capacity

This high-tech model is capable of carrying 40% more load than a standard technology tyre.

However, by reducing speed this load bonus can increase further, which is a particularly interesting advantage for pulling bigger implements or heavier trailers.

The contact patch with the ground increases with the size of the implements without ever compacting the soil.

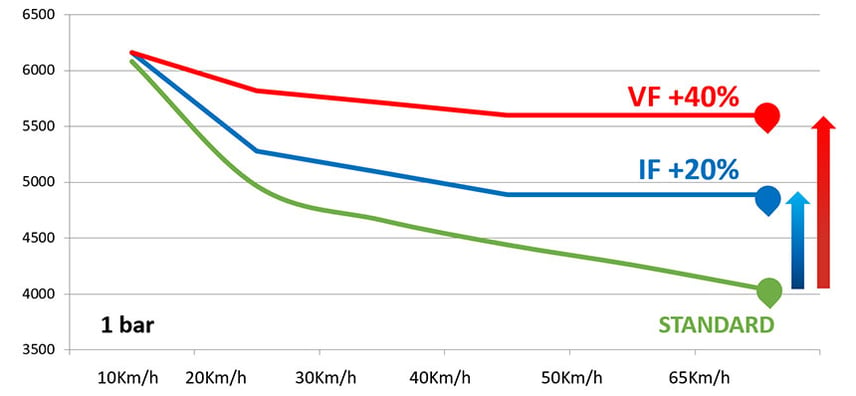

The load bonus of a new generation VF tyre

increases even further when you reduce speed,

without compacting the soil

An example of load in identical conditions

Here is the comparison between a new generation VF tyre size 710/70 R42 and a standard tyre of the same size:

- New generation VF tyre: maximum load 5,850 kg with a pressure of 1 bar and a speed of 20 km/h,

- Standard tyre: maximum load of 4,750 kg again at 1 bar and with a speed of 20 km/h,

i.e. a difference of 1,100 kg in favour of the new generation VF tyre at the working speed and still a difference of 1,545 Kg in favour of the VF tyre at 65 km/h.

Less pressure to preserve the soil

The capacity of these new tyres to work at 0.6 bar with more load gives you the possibility of using bigger, heavier implements, which will increase your productivity.

By driving with a low inflation pressure, you will obtain a bigger, longer and wider soil footprint with no risk of soil compaction.

More traction, less rolling resistance

Thanks to a better developed design of the lugs, whose thickness, angle and size have been optimised, the penetration of the lugs into the ground is optimal with VF tyres.

Working at low pressure gives you a longer soil footprint, so there are more lugs working together at the same time. The tyre’s capacity to transmit tractive force horizontally is multiplied.

Rolling resistance is reduced with a minimum amount of slip and maximum self-cleaning, irrespective of the type of soil, including heavy, wet soil.

Reduced fuel consumption

As the lugs have a better grip, new generation low-pressure VF tyres slip much less, allowing the engine to transmit its power to the ground more effectively.

Throughout the lifespan of your tyre, you can save around 35 litres of fuel per 50 hectares worked compared to a standard tyre.

With this model, the soil is not compacted, you no longer need to carry out any deep tilling or soil aeration work to obtain the same yield. This means that you can really make massive fuel savings.

Ideal with a remote tyre inflation system

These tyres will give the best of their capacities with a remote inflation system (TPMS or CTIS).

This new generation tyre links the load bonus to a reduction in speed, but combined with a remote inflation system makes it possible to adjust pressure exactly to your environment in real time.

With this set-up you obtain the following benefits:

- Immediate pressure adjustment: you no longer have to stop to make an adjustment.

- Optimal time saving: pressure settings are managed directly from your tractor cab.

- Fuel saving: up to 30% on the road, and even more in the fields by adjusting pressure to speed.

- Soil preservation: compaction is reduced thanks to the use of better settings directly on entering the fields.

- The tyres are preserved by increasing inflation pressure from the cab, without stopping, before driving at speed on the road.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Technical data for agricultural tyres – Agricultural tyre performance – Air pressure advice, Solutions to avoid soil compaction – Sprayer tyre pressure – Why and how to ballast your tractor tyres – etc.

To take it one step further and increase the profitability of your farm, les Experts du pneu provide a free, highly detailed eBook which explains the essential role of the agricultural tyre in your productivity.

Most people who read this article have also read some of the following articles which are listed by order of popularity:

- Buying guide: 10 important tips for choosing the right farming tyres

- What materials guarantee the quality of your tractor tyres

- Which agricultural tyre configuration is suited to each use

- The best agricultural tyres for agricultural contracting companies

- How do my tractor tyres impact my vineyards?

- Agricultural contracting companies: why to invest in a tire inflation system

- Technologies that make the difference for quality agricultural tyres

- Changing agricultural tyre series: how does it work?

- Which agricultural tyre technology to choose? Standard, IF or VF?

- The advantages of a good agricultural tyre in wine and fruit growing activities

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *