It’s true that agricultural tyres all look alike and it may appear difficult to choose between the models on offer, because there is no similarity between the price of a standard tyre and a top-of-the range tyre.

It would be very easy to draw up a parallel with the luxury goods sector where we are used to finding commodity items with prohibitive prices just because of the prestigious brand name. For the agricultural tyre, it’s a very different context because it is not a question of unnecessary luxury, but rather a production tool that you are going to use every day. The top-of-the-range model is produced with substantial technological differences that will significantly transform the results of your work.

Here are the technologies that really make the difference in the production of quality agricultural tyres:

1. What is the mixture of rubber used to reduce wear and increase tyre life?

Tyres are alike, the rubber is black and there seems to be no visible difference between tyre models. So there is no way of guessing, just by looking at them, what the different components are that are used in the rubber compound.

This is a crucial aspect which has a direct impact on the tyre’s selling price. Indeed, as you cannot check anything, manufacturers of low-end tyres can easily reduce or withhold the most expensive ingredients which nonetheless give the tyre all its qualities.

On the other hand, a top-of-the-range tyre is often the result of research and development and contains materials which improve its capacities, its lifespan or its resistance to wear…

For example, in Bridgestone’s VX TRACTOR, VT TRACTOR and VT COMBINE tyres there are many ingredients, selected for their qualities and the benefits they bring to tyres.

Here are a few examples of some ingredients that make the difference:

Rubber

This is the basic tyre ingredient and can include mostly natural rubber or synthetic rubber derived from petroleum, which is much cheaper.

Obviously natural rubber has irreplaceable qualities of elasticity, resistance, adherence and impermeability.

The Bridgestone group has chosen to use a large quantity of natural rubber to increase the quality and the flexibility of its tyres. The group has its own rubber tree plantations, which are run sustainably. This ecological management of resources allows it to balance supplies, with a long-term environmental vision, as well as to procure quality rubber.

Ecological harvesting of natural latex at Bridgestone’s plantations

Ecological harvesting of natural latex at Bridgestone’s plantations

Carbon black

This additive is a very important ingredient which is somewhat scarce in standard tyres, yet this is what increases the rubber’s resistance to cuts and improves its resistance to wear (as such extending tyre life).

Vegetable oils

Cheap petroleum oils are used in standard tyres simply to improve the blending of the rubber. For Bridgestone tyres, these oils have been replaced by a new composite blend containing vegetable oils which give the rubber better resistance to damages and better resistance to wear.

Sulphur

This is an essential additive for good vulcanisation. This is the tyre curing process which creates molecular chains that transform the rubber from plastic to elastic. In low-end tyres, the insufficient quantity of sulphur prevents perfect cohesion between the materials which means that these tyres are not at all resistant to wear.

Bridgestone’s research and development teams have determined the optimal quantity of sulphur needed to increase mechanical resistance while preserving the tyre’s elasticity.

The sulphur also limits the tyre’s sensitivity to variations in temperature.

2. What structural design allows you to considerably increase the load or to work at very low inflation pressure?

In addition to a selection of quality ingredients for the rubber, what increases the tyre’s resistance is the design of its casing. This is the fruit of thousands of hours of research and development for top-of-the-range tyres which enable a highly technical assembly of the materials to obtain a tyre with exceptional characteristics.

Like for the rubber, it’s what’s inside the tyre that makes all the difference.

For tough work which puts your machinery under severe strain,

the steel mesh provides excellent resistance to impacts, punctures and flexion, but makes the tyre rigid, which is perfect for heavy duty construction vehicles, or for special tyres, such as narrow tyres or forestry tyres.

For optimal use with field crops where soil preservation is crucial,

nylon, polyester or rayon fibre mesh is used. This mesh strengthens the structure of the tyre, while maintaining all its suppleness, essentially for work at very low pressure and to preserve the soil in your fields from compaction.

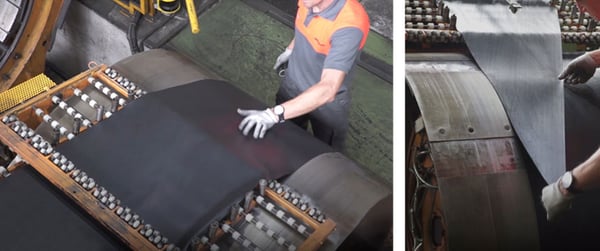

The technologies at the service of uniform assembly of a quality tyre

The highly complex assembly of the different materials: fabric, metal, rubber to make up the casing mesh of a top-of-the-range tyre takes account of the interactions of each element with its environment.

Ply assembly. Bridgestone factory

Ply assembly. Bridgestone factory

Each part of the tyre has a specific function which gives the overall tyre all its qualities. For example:

The sidewalls must provide maximum flexibility if you wish to work at low pressure, but good resistance to impacts and cuts.

The tread is the tyre’s most complex assembly which has several functions. It is the result of several overlapping layers of rubber which make it possible:

- For the stabilising plies to have perfect command of steering and good transmission of engine torque to the ground.

- For the protective plies:to provide maximum resistance to wear and to external hazards.

This is where a major difference in price lies, with a very low quantity of plies for standard tyres and 6 or more stabilising and protective plies for top-of-the-range tyres.

The tyre beads are the link between the tyre and the rim. With the increasing power of tractors, the transmission of torque to the rim is becoming extremely high. The construction of the bead, which contains steel ply, requires a very high level of research and development and technical sophistication to ensure complete airtightness in all circumstances.

3. What tread design gives you much better traction?

If the rubber is top quality and the casing the result of several years of research and development, the form of the lugs on the tread also plays a major role in avoiding slippage and transmitting tractive force.

You have no doubt noticed that the form of the lugs is not exactly the same for each brand of tyre. In the case of top-quality tyres, this is not just a matter of appearance.

Tyre lugs are one of the main vectors of transmission of power to the ground. They grip into the earth, generating a horizontal compression which makes it possible to use most of the engine torque for traction.

The profile design of the leading edge of the lugs has been optimised to avoid soil disturbance which generates a loss of efficiency and reduces the tyre’s self-cleaning capacity. The highly specific profile angle of the Bridgestone tyres provides better grip and perfect self-cleaning of the surface of the tyre before it reconnects with the ground.

On the road, the lug profile of the tread must also allow for travel at speed (up to 70 km/h) without vibration and in comfortable driving conditions, good road handling (no swerving when cornering) and ensure good braking capacity in complete safety.

THE ROLE OF INVOLUTE TECHNOLOGY IN TRACTION

4. What are the benefits of a more technical top-of-the-range tyre?

The engine power of two tractors may be very different, even if the external bodywork is the same. The same is essentially true for tyre quality: what is important is the internal components of the tyre.

The main disadvantage for the tyre is that you cannot see what’s inside the rubber, unless you cut it, which would make the tyre unusable.

While this is not easily visible, quality tyre manufacturers give you indications to guide you without having to cut your new tyres:

- A VF tyre such as the VT-TRACTOR can carry 40% more load than a standard tyre, which is proof that the trye structure is well above average.

- A VF tyre can work at very low pressure: 0.6 bar, which is proof that the sidewalls are extremely supple and resist flexion without any long-term alteration of the tyre.

- A VF tyre lets you save time by avoiding inflation pressure changes between the road and the fields, which is proof that its design protects against wear even if you do not have the correct inflation pressure and whatever your speed.

- Latest generation VF tyres such as the VT-TRACTOR tyre are designed to include an on-board inflation system (CTIS: Central Tyre Inflation system) so that you can switch to optimal tyre pressure in the field and on the road at any time.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Technical data for agricultural tyres – Agricultural tyre performance – Air pressure advice, Solutions to avoid soil compaction – Sprayer tyre pressure – Why and how to ballast your tractor tyres – etc.

To take it one step further and increase the profitability of your farm, les Experts du pneu provide a free, highly detailed eBook which explains the essential role of the agricultural tyre in your productivity.

Most people who read this article have also read some of the following articles which are listed by order of popularity:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *