When you are looking to optimise farm profitability, the first reflex is often to invest in new machines, modernise tooling or rethink crop practices. One element is often neglected: the tyres of your tractors and agricultural machinery. At first glance, they seem to play a purely mechanical role, but their influence on productivity and profitability is far more important than you might think.

Tyres are not just a simple piece of equipment, they are performance tools. Poor grip, excessive slip or unsuitable rolling resistance may lead to extra fuel consumption, premature wear or even damage your soil.

All these factors accumulate to increase operating expenses and reduce the efficiency of your work. On the other hand, a well-suited, high-tech tyre alone can improve traction, reduce fuel consumption and protect your soil, thus improving your yields.

In this article we will explore in detail how a simple change in tyres can transform your daily life and help you improve profitability. You will be surprised to discover just how much this often underestimated part of your equipment can have an impact on your farm.

1. A good agricultural tyre must reduce fuel consumption

Less resistance equals less consumption

The more rolling resistance there is, the more energy you require to move forward.

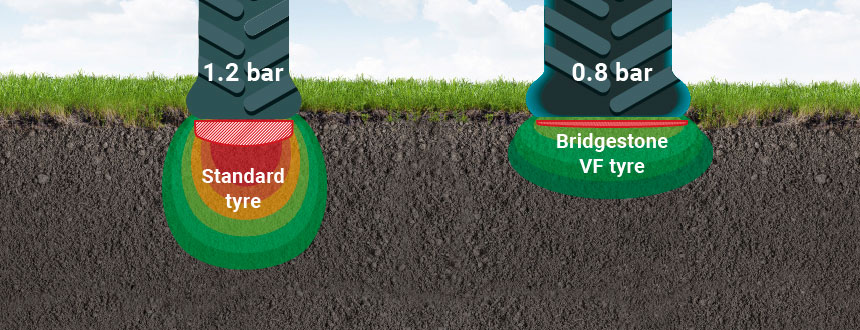

On soft or very wet ground, a standard tyre that you overinflate to bear the weight of your implements will meet with strong rolling resistance because it sinks deep into the ground.

The earth in front of the tyre is a perpetually renewed obstacle, which significantly opposes its progression.

This will force the tractor engine into producing a greater effort, which in turn increases fuel consumption.

rolling resistance increases

High-tech agricultural tyres are designed to reduce this rolling resistance thanks to their larger contact patch with the ground and specific lug profiles. This leads to fuel savings of up to 30%.

Low-pressure tyres, the winning solution

To improve traction and grip, you can use low-pressure tyres.

By reducing the pressure in the tyre, the contact patch with the ground increases. This larger contact area allows more lugs to grip into the ground simultaneously. This improves the traction capacity and reduces fuel consumption.

EXAMPLE: To understand the practical benefits of good traction better, let’s look at a comparative test carried out with VF (Very High Flexion) tyres and standard tyres.

The results speak for themselves:

- REFERENCE MEASUREMENT:

The VF VT-TRACTOR 650/85 R38 tyre has a rolling circumference of 6122 mm. These are the manufacturer’s theoretical reference data → Number of reference wheel rotations = 200 m / 6122 = 32.67 wheel rotations are necessary to travel 200 m.

compared to standard tyres on the right

- TRACTOR 1 John Deere 6215R, with identical implements for both tractors.

Equipped with VF VT-TRACTOR 650/85 R38 tyres with a front/rear inflation pressure of 0.8 bar:

- Over a distance of 200m travelled by the tractor

→ 8.3% slip ratio = 35.40 wheel rotations = 216.70 metres travelled by the tyres

- Over a distance of 200m travelled by the tractor

- TRACTOR 2 John Deere 6215R, with identical implements for both tractors.

Equipped with STANDARD 650/85 R38 tyres of a competitor brand, with a front/rear inflation pressure of 1.4 bar:

- Over a distance of 200m travelled by the tractor

→ 17.69% slip ratio = 38.45 wheel rotations = 235 metres travelled by the tyre

- Over a distance of 200m travelled by the tractor

Results of the traction test:

3.05 wheel rotations less for the VF VT-TRACTOR tyre, i.e. 20 metres less tractive effort for every 200 metres.

The test was carried out several times to be sure that the performance is not linked to a different cause. All the tests produced similar results.

This difference of nearly 10% less slip leads to a shorter distance covered by the VF tyres, which means less tractive effort required by the tractor and therefore less fuel consumption. Each additional wheel rotation effectively demands more energy consumption.

Why such a difference?

VF tyres used at low pressure increase the contact area with the ground. This characteristic, together with an optimised lug structure, maximises the transmission of power to the ground and reduces energy loss.

TO BEAR IN MIND

As the distance travelled by the tyre is not the same as the distance travelled by the tractor, fuel consumption is effectively impacted by your tyre technology.

2. A good agricultural tyre must have a longer wear life

A lot of slip leads to premature tyre wear

Imagine pulling a heavy load on soft, wet soil with slippery shoes, you will slip and slide without much traction efficiency but causing rapid wear to your shoes.

Slip is when the tyre slides on the ground more than it grips. It’s the biggest enemy of agricultural tyre longevity. It happens when the tyres are unsuitable, such as with bias ply tyres, or with the wrong inflation pressure, or even tyres which do not correspond to the weight of your implements.

Excessive slip, due to rubbing, wears the rubber of your tyres more rapidly, obliging you to replace them often.

VF tyres: less slip leading to a longer wear life

VF (Very High Flexion) tyres are specially designed to work at low pressure.

This characteristic gives them a longer, wider soil footprint, which improves adherence and minimises slip.

It’s easy to control the slip ratio, which decreases, meaning that the work is done more rapidly, your tyres wear less quickly and their lifespan is increased. In the end you save money because you have to replace your tyres less frequently.

3. A good agricultural tyre must protect your soil to maintain your yields

Healthy soil is the cornerstone of prosperous farming. But soil compaction, caused mainly by the repeated toing and froing of agricultural machines, is a real curse which endangers soil fertility.

with unsuitable tyres destroys your soil

This can be avoided if you are equipped with good tyres. You must use tyres that are suited to the type of soil on your farm and the activities carried out by your machines. A good agricultural tyre must preserve your soil as much as possible.

The consequences of soil compaction

The structure of compacted soil has been altered. The pores, those tiny spaces which allow air, water and nutrients to circulate, are reduced or obstructed. This limits root development, asphyxiates the micro-organisms in the soil and reduces its capacity to retain water.

In the long term, this leads to lower yields, greater sensitivity to erosion and an overall deterioration of the quality of the soil.

High-tech tyres for well-preserved soil

High-tech agricultural tyres, such as VF tyres, are designed to reduce their impact on the soil.

Thanks to their more flexible casing and their ability to work at low pressure, they spread the weight of the machine over a longer, larger surface area. It’s like standing on deep, fresh snow with snow shoes rather than boots: when spread over a larger surface area, the pressure to the ground is lower.

This reduction in pressure limits the compaction of the different layers of soil and encourages better crop development. Obviously, to obtain a good result, it is necessary to use the same high-tech tyres for all 4 tractor wheels.

4. Bridgestone’s VF VT-TRACTOR tyre: a profitable investment

Bridgestone’s VT-TRACTOR tyre represents a significant set forward in the field of agricultural tyres.

Its technical characteristics give it considerable advantages; they are capable of carrying heavy loads while keeping a minimal inflation pressure. VF tyres limit soil compaction, and are designed to protect crop root systems as much as possible.

Optimised performance

Thanks to its specific design, the VT-TRACTOR tyre offers better traction and reduces rolling resistance. This leads to a decrease in fuel consumption and a lower slip ratio, thus preserving the tyres from overly rapid wear.

Innovative technology even in the lugs

The “Involute” lugs of the VT-TRACTOR tyre play an essential role in improving traction. Their specific form allows for a better grip on the ground, even in difficult conditions.

The tyre lugs are the main transmission point for engine power to the ground. They grip into the ground through the leading edge of the lug, then take hold on the ground to use torque with a horizontal downwards movement which transmits the tractive effort perfectly.

When it leaves the ground, the classical lug causes soil displacement which lifts up the earth and reduces the tyre’s self-cleaning capacity.

The Involute design of the Bridgestone tyres has been optimised to avoid this soil displacement effect. The very specific lug profile allows for excellent self-cleaning of the tyre surface before it comes back into contact with the soil.

Soil preservation for sustainable yields

The VT-TRACTOR tyre is designed to work at a very low inflation pressure, from 0.6 to 0.8 bar, while carrying heavy loads.

This capacity allows you to adapt the tyre to different working conditions, whether on soft ground or in difficult conditions, by reducing the pressure to the ground, the VT-TRACTOR tyre limits compaction.

This preserves the natural structure of the soil, encourages good root penetration, better retention of water in the deep layers and preservation of soil fertility on a long-term basis.

at an inflation pressure of 0.6 bar

CONCLUSION:

A strategic investment for your farm

Agricultural tyres, whose role is often underestimated, are an efficient way of optimising the profitability of your farm.

Beyond their simple support function, they improve machine performance and soil preservation.

Investing in premium tyres, like Bridgestone’s VT-TRACTOR tyre, is a way of opting for performance, economy and durability.

It also means moving towards more environmentally friendly and more profitable farming.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Technical data for agricultural tyres – Agricultural tyre performance – Air pressure advice, Solutions to avoid soil compaction – Sprayer tyre pressure – Why and how to ballast your tractor tyres – etc.

To take it one step further and increase the profitability of your farm, the blog Bridgestone-agriculture.eu provide a free, highly detailed eBook which explains the essential role of the agricultural tyre in your productivity.

Most people who read this article have also read some of the following articles which are listed by order of popularity:

- Buying guide: 10 important tips for choosing the right farming tyres

- How to get a better warranty for your agricultural tyres?

- A long-lasting agricultural tyre also leads to better productivity

- Here is the new generation of high-tech agricultural tyres

- Testimonial: What are the qualities of a premium agricultural tyre

- What is the best agricultural tyre for autonomous tractors?

- Which agricultural tyre boosts the performance of your agricultural contracting company?

- Good agricultural tyre option choices when buying your new tractor

- Farmer testimonials on Bridgestone agricultural tyres

- What are the advantages of a high-tech IF VF CFO tyre?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *