While it is easy to minimise the impact of the tyre’s contact patch with the ground, it is precisely these few square centimetres of additional contact area which turn out to be at the very heart of efficiency in terms of traction and tractor handling capacity. The few lugs (which seem to be a minor aspect of the tyre) in contact with the ground are the promise of substantive work, ensuring optimal transmission of tractor power to the ground. Hence it becomes clear that the ingenuity of the design details of the tyre, such as the increased size of the contact patch resulting from adding a few extra square centimetres, the precision in the dimensions of the tread, a more ergonomic lug design and the use of materials that are highly resistant to wear, becomes crucial.

When research and development places the level of precision at the heart of its concerns, transforming each detail into a field of in-depth research, the result is a product that not only defies expectations, but also redefines the industry standards.

This new generation of agricultural tyre, with its unprecedented level of technicality, exemplifies a design whose every detail is scrupulously thought out and where each improvement percentage contributes towards shaping a truly unbeatable product. In this article we look in detail at the technical evolutions of the new generation agricultural tyre:

1. A wider tread to improve traction

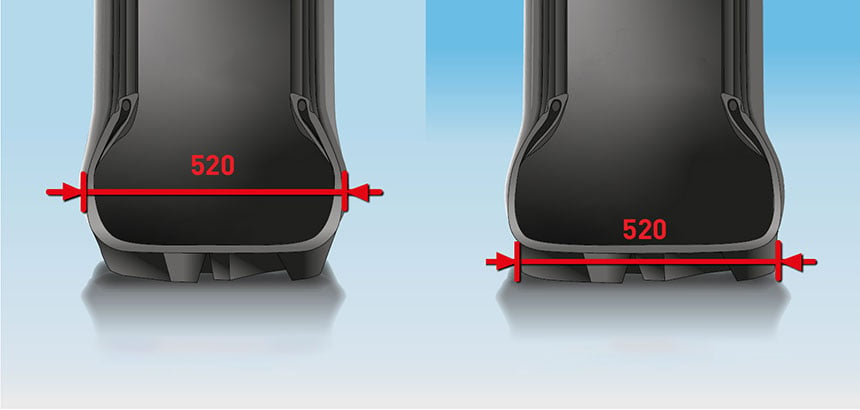

The width of an agricultural trye tread plays an essential role in optimising traction and tractor efficiency. Contrary to popular belief, the section width indicated on the tyre sidewall does not correspond exactly to the width of the tread in contact with the ground.

What is the exact width of the tread?

The width of the tread is indicated by the first figure of the product designation on an agricultural tyre’s sidewall. In theory, it does not correspond to the width at the level of the tyre shoulders, but the distance between the right and left sidewall of a tyre.

For example, a 580/70 R42 tyre may have an average section width of 580 millimetres from sidewall to sidewall, although the actual width of the tread in contact with the ground is less than this.

The advantages of the VX-R TRACTOR tread

Bridgestone’s VX-R TRACTOR tyre represents a major breakthrough in terms of agricultural tyres. It offers a section width in contact with the ground that is perfectly equal to what is indicated on the sidewall, unlike its competitors.

A wider tread makes it possible to spread the weight more evenly over a larger soil footprint, which limits the amount of soil compaction caused.

Thanks to its innovative design, this high-tech tyre has many strong points:

- More efficient transmission of power to the ground.

- Better traction.

- Increased stability.

- Reduction of slip.

- Considerable reduction of compaction.

The VX-R TRACTOR helps improve work efficiency even in wet conditions. It stands out from classical models by offering an advanced technological solution for farmers looking to optimise their work rate.

2. Optimised lead to reduce agricultural tyre wear

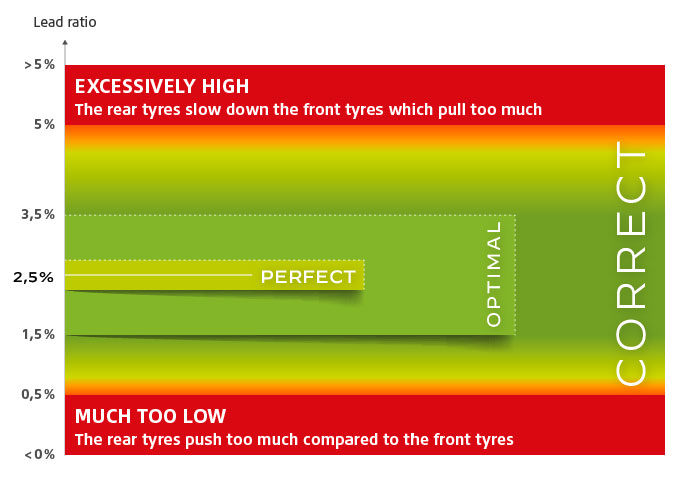

On a four-wheel drive tractor with different sized tyres, the rotation speed of the rear tyres (which are bigger) is not the same as for the front tyres (which are smaller). The lead ratio is an essential parameter which makes it possible to define whether the front and rear axles are perfectly synchronised, despite the different rotation speeds of the front and rear wheels.

What happens if you don’t have a correct lead ratio?

Incorrect lead can cause uneven wear to tyres, excessive slip, mechanical transmission problems and reduce the lifespan of your agricultural tyres.

If the lead ratio is too high, generally above 5%, the front tyres will pull too strongly, leading to too much slip at the front and rapid wear to the lugs.

On the other hand, if lead ratio is close to or below 0% (lag), the rear axle will push the front axle, which reduces the tractor’s traction efficiency and increases fuel consumption, which in both cases causes a risk of mechanical damage to the transmission elements.

The advantages of the VX-R TRACTOR tyre in terms of lead

The VX-R TRACTOR tyre stands apart due to its design which aims to achieve ideal lead of 2.5%. It has been designed with an optimal rolling circumference, so that each front/rear combination can contribute to the efficiency of your agricultural equipment.

Thanks to its innovative design, this new generation agricultural tyre provides many benefits:

- Well balanced lead.

- Optimal traction.

- Reduction of wear.

- Better energy efficiency.

Having a good lead ratio improves the energy efficiency of the tractor, reducing fuel consumption and extending the useful life of the tyres. The perfect synchronisation between the front and rear axles of the tractor leads to optimal adherence to the ground and excellent traction.

Investing in VX-R TRACTOR tyres is a way to ensure that your tyres last much longer thanks to a perfectly controlled lead ratio. This allows you to keep your tyres in excellent condition, to reduce your operating costs and improve overall productivity.

3. A longer lifespan to make real savings

When you choose your new agricultural tyres, the expected lifespan of your equipment is a vital factor that is often neglected to the detriment of the purchase price, which seems to be more important. Yet considering the replacement of your tyres as an investment over several years is a better strategy, as you can’t be sure that opting for the cheapest tyres is really the best choice economically.

What are the disadvantages of a discount tyre, which is generally less expensive to buy?

Opting for cheap or discount tyres may seem to be an economical choice at the time of purchase, but there are many disadvantages.

To limit the selling price, manufacturers effectively have to choose a more simple design using cheaper materials, which may turn out to be counterproductive in terms of yield and work rate. In order to cope with heavy loads, the tyres must be highly inflated to avoid damages, which increases the risk of earth accumulating between the lugs and reduces adherence in wet conditions.

As a result, the tractor needs more power which is not efficiently converted into work, leading to a slower work rate, more fuel consumption and potential damage to the soil.

A discount tyre has less thick rubber

The tread of a cheap agricultural tyre has less plies as part of the manufacturing process and is often made from lower quality rubber, with less natural and more synthetic rubber, which wears more quickly, reducing the overall lifespan of the tyres.

In addition, as the sidewalls are less thick and therefore less resistant, they are more sensitive to cuts caused by branches or silex, which increases the risk of punctures.

In the end, all these disadvantages lead to a limited lifespan for cheap agricultural tyres, which have to be replaced more frequently. This means additional costs or unexpected interruptions if the equipment is damaged as a result of its insufficient resistance capacity.

The advantages of the VX-R TRACTOR tyre

To avoid these problems, the best advice is to opt for more high-tech agricultural tyres such as the VX-R TRACTOR tyre.

It has been designed to last. Its rubber compound includes a mixture of high quality components, based on plant-based oils specifically developed to increase resistance to damage and to wear.

Its robust casing has been redesigned to obtain a wider tread. It contains a large number of plies which ensure greater resistance.

Thanks to these characteristics, this high-tech tyre has an extended wear life, which is a source of savings in the long run.

The VX-R TRACTOR tyre brings many advantages:

- Materials that are more resistant to wear and to damages.

- A longer wear life leading to a reduction in costs linked to frequent tyre replacement.

- Reliable performances in the field with an excellent work rate.

- More comfort and stability during travel by road.

4. Sustainable development to reduce energy consumption

Investing in so-called “sustainable” agricultural tyres must not simply mean that the manufacturer takes part in recycling operations by contributing to some ecological organisation. It must go much further to allow you, as a farmer, to benefit financially from this sustainability.

Where does the interest lie for you in having a sustainable agricultural tyre?

To be able to consider that your new agricultural tyre is really “sustainable”, it must offer, at the least, the following advantages:

- Soil preservation: it reduces soil compaction and keeps your land healthy to encourage an increase in your yields.

- Wear resistance: it has a longer wear life, which reduces the replacement frequency which saves you money and has a positive impact on the environment.

- Reduction of fuel consumption: a better designed tyre requires less force to operate and will need less power, resulting in substantial fuel savings in the long run.

ENLITEN technology for the VX-R TRACTOR tyre

The VX-R TRACTOR tyre is a good example of a tyre that was designed to be in tune with sustainable development notions. It uses the Bridgestone “ENLITEN” technology which guarantees:

- A more robust casing structure, with materials that are less sensitive to wear, to last much longer over time.

- A design which reduces rolling resistance and ensures perfect lead, resulting in a real decrease in fuel consumption.

- The use of sustainably managed raw materials (group Hevea tree farms for autonomy in the production of rubber).

- “Involute” design lugs which limit loss of energy, reduce soil disturbance and improve tractive force.

- A wider tread for an excellent grip on the ground and better traction.

Opting for the VX-R TRACTOR tyre corresponds to an investment in sustainability, profitability and soil preservation.

CONCLUSION

In a constantly evolving agricultural world, where each detail plays a crucial role, a revolution is underway to maximise efficiency and productivity thanks to the emergence of a new generation of agricultural tyre. Each innovation, each breakthrough in precision, materials and design, is shaping your future tyres, making tractors not only more efficient, but also more respectful of the soil on which they work.

By minimising their impact on the ground and maximising tractive force, these new generation agricultural tyres are paving the way for a future in which technology and agriculture unite for a more sustainable, efficient and high-performance approach, illustrating perfectly how technological innovation can be at the service of more respectful, yet more productive farming.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Technical data for agricultural tyres – Agricultural tyre performance – Air pressure advice, Solutions to avoid soil compaction – Sprayer tyre pressure – Why and how to ballast your tractor tyres – etc.

To take it one step further and increase the profitability of your farm, les Experts du pneu provide a free, highly detailed eBook which explains the essential role of the agricultural tyre in your productivity.

Most people who read this article have also read some of the following articles which are listed by order of popularity:

- Buying guide: 10 important tips for choosing the right farming tyres

- How do my tractor tyres impact my vineyards?

- Agricultural contracting companies: why to invest in a tire inflation system

- Technologies that make the difference for quality agricultural tyres

- Changing agricultural tyre series: how does it work?

- Which agricultural tyre technology to choose? Standard, IF or VF?

- The advantages of a good agricultural tyre in wine and fruit growing activities

- What are the differences between the 3 generations of VF tyres?

- How to get a better warranty for your agricultural tyres?

- A long-lasting agricultural tyre also leads to better productivity

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *