Your farm specialises in field crops. For wheat, rapeseed, barley, corn or beetroot… and for your various ploughing, sowing, spraying or harvesting activities you can increase your yield by optimising your equipment and in particular your tyres, which are the sole connection between the soil and your farm machinery.

There are as many different tyre models and possibilities as there are machines and activities, so how can you find the tyre that is most suited to crop farming?

It's important to be aware that if you use the best tyres, you will see the gains on all aspects of your activity: increased traction, tasks achieved more quickly, less soil compaction, less spinning, no more adjusting pressure, less fuel consumed and higher yields.

1. Which type of casing is best suited to field crops: radial or diagonal?

While Radial tyres tend to dominate the tyre market, for each individual activity, there is a tyre designed specifically.

For field crop farming, choosing the right tyre casing is vitally important. There are two main categories on the farm tyre market: diagonal casing and radial casing.

The casing of each farming tyre is easy to recognise due to their distinct treads and specific characteristics.

- DIAGONAL CASING: with a recognisable rounded shape, this casing is composed of layers of nylon cords crossing diagonally making the sidewalls and treads dependent on each other. This design results in a lack of flexibility, as to improve the tread resistance, the number of cord layers must be increased, and this thickness is also applied to the sidewalls.

With a diagonal casing tyre, soil compaction will be greater as the distribution of pressure on the ground is not evenly spread out contrary to radial casing tyres.

- RADIAL CASING: square shaped, the structure of radial tyre is more like a caterpillar. The sidewall cord layers are perpendicular to the wheel axis. These layers are independent of the tread layers encircling the tyre. This type of structure considerably reinforces the tread without stiffening the sidewall. The tyre is much strengthened where it contacts the soil while remaining extremely flexible.

The flexibility of a radial carcass tyre provides better load bearing, increases traction and reduces smoothening of the lugs. With its square shape, wear is evenly spread out across the tread.

Considering the characteristics of each casing, radial agricultural tyres are recommended for farms specialising in field crops. Distribution of pressure on the soil is perfectly spread out with a radial casing as the tread is aligned with the ground, it improves traction and improves the transmission of the tractor’s power to the ground, the flexibility of the casing makes it possible to lower the pressure for better protection of the soil structure.

2. Influence of tyres on soil compaction: which is the most suitable model?

Did you know that excessive soil compaction can reduce your yield by 5 to 30%?

This phenomenon is essentially due to repetitive activities of heavy machinery, in particular when the soil is very wet. As the tyre is the main element in direct contact with the soil, it has mechanical actions which can be more or less visible. They can result in soil compaction in your fields which directly impacts the development of the root systems and reduces your crop yield.

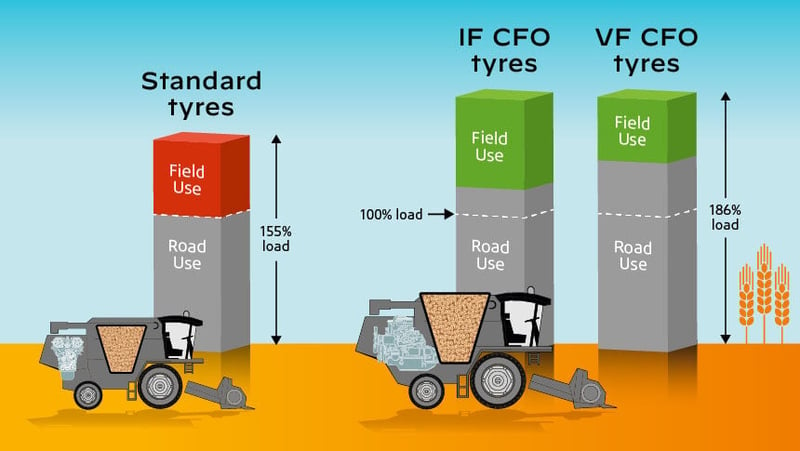

As well as choosing a radial tyre, working with low pressure tyres reduces soil compaction while maintaining the tyre structure. Among the models available on the market, VF (Very High Flexion) farming tyres are highly recommended for field crops. Designed specifically to protect the soil structure, they can carry up to 40% more weight than a standard tyre, using equivalent or lower pressure. Their sidewalls are extremely flexible for increased stability even in case of heavy loads or low pressure.

As well as choosing a radial tyre, working with low pressure tyres reduces soil compaction while maintaining the tyre structure. Among the models available on the market, VF (Very High Flexion) farming tyres are highly recommended for field crops. Designed specifically to protect the soil structure, they can carry up to 40% more weight than a standard tyre, using equivalent or lower pressure. Their sidewalls are extremely flexible for increased stability even in case of heavy loads or low pressure.

3. Why choose a low-pressure high-volume tyre model?

On farms specialising in field crops, heavier and more powerful machinery is becoming the norm. While they are very efficient in terms of production, they tend to accelerate soil compaction.

So, what is the solution?

The best answer is to equip your machinery with farm tyres designed to carry the necessary load, but capable of working at low pressure. To achieve this, don’t hesitate to use farm tyres with a high surface of contact with the ground and a large volume of air to distribute the tractor’s weight across a greater area. This method reduces the pressure of contact and the impact on the soil structure, making your work more productive.

Tyre manufacturers currently sell all types of agricultural tyres in almost every size. For the same diameter, you can find different tyre widths:

- Narrow

- Standard

- Wide

- Large volume or “low pressure”

Contrary to what many people think, low pressure tyres are not designed solely for harvesting machines or for farm trailers. The are increasingly used on farm tractors to remedy the problems of soil compaction and rut creation. With their increased width, this type of tyre contains a large volume of air to carry heavy loads at moderate pressure, reducing the burden applied to the soil.

4. Can you avoid the need to adjust tyre pressure when changing from road to field? Which tyre model should you choose?

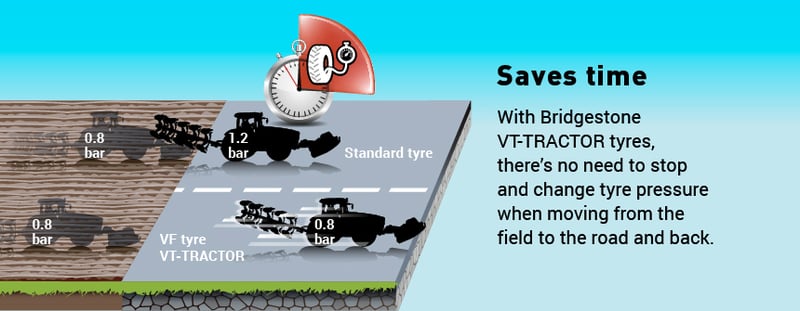

Ideally, you should not be using the same tyre pressure on road and field surfaces: low pressure for field work and high pressure on the road. If you are working fields that are a good distance from each other, you have to get up and down from your cabin to adjust the pressure each time you change ground surface. The question is how to avoid this problem. There is a tyre which will allow you to continue to work with the same pressure without having to think too much about it.

With their innovative design, with low pressure VF tyres you:

- Work with low pressure whatever the soil type.

- Save a lot of time.

- Avoid spinning.

- Increase your productivity.

- Optimise your crop yield while protecting the root system of your plants.

With these new generation tyres, you can maintain the same tyre pressure in the field or on the road, whatever the load to be transported. For a given load, they enable you to use the same pressure. Their sidewalls were developed to widen the tread contact length, while the pressure can be reduced to between 0.8 to 1.2 bar.

You will no longer need to inflate or deflate your tyres to limit soil compaction, whatever the type of terrain, the load, or the activity. You can also reduce the pressure of your tyres by 40% without impacting their lifespan and their performance. This is made possible through an innovative design in the VF tyre casing. The materials used in its structure are highly resistant to knocks and easily recover their initial shape.

You will no longer need to inflate or deflate your tyres to limit soil compaction, whatever the type of terrain, the load, or the activity. You can also reduce the pressure of your tyres by 40% without impacting their lifespan and their performance. This is made possible through an innovative design in the VF tyre casing. The materials used in its structure are highly resistant to knocks and easily recover their initial shape.

5. How to increase the tractive force of your machinery?

To increase your yield, transport heavier loads and work more quickly, you need to increase the tractive force of your machinery by choosing farming tyres which best grip the soil. To achieve this, choose a tyre with a lug angle which is low in relation to the road. This provides you with a contact surface perpendicular to the driving direction thus optimising the tractive force.

When you buy your tyres, avoid discount models whose tread angles are too wide, as the more the treads are parallel to the driving direction, the higher the slip ratio, increasing your fuel consumption especially on loose or wet soil. The more you spin, the more you wear out your tyres.

You can look for new generation tyres equipped with treads with multiple angle or curved lugs. These models are the best compromise between the maximum tractive force and optimal self-cleaning. Some tyres are even equipped with lugs specifically designed to dig into the soil without a shovel effect, to optimise traction.

To optimise the tractive force, choose wide, low-pressure VF tyres. With their reinforced and flexible sidewalls, they provide maximum flexibility and can be adjusted to extremely low pressure to increase the surface in connection with the ground, increasing the contact of the lugs designed to transmit the tractive force.

To optimise the tractive force, choose wide, low-pressure VF tyres. With their reinforced and flexible sidewalls, they provide maximum flexibility and can be adjusted to extremely low pressure to increase the surface in connection with the ground, increasing the contact of the lugs designed to transmit the tractive force.

In conclusion, for farms specialising in field-crops and wishing to improve their productivity, the best tyres are undoubtedly those with VF technology, preferably larger and wider to protect your soil while increasing traction.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc…

Most people who read this article have also read some of the following articles which are listed by order of popularity:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *