Efficient management of soil compaction is a crucial, often underestimated, challenge which has a direct impact on farm productivity. This article looks at the significant impact that tractor tyres have on soil compaction, which is a slow, insidious problem that can considerably reduce a field’s production capacity, often without the farmer realising.

Through studies, expert analyses and technological breakthroughs, we will show how a judicious choice of tyres, combined with suitable use, can prevent soil compaction, protect soil fertility and optimise productivity on a long-term basis.

1. Consequences of soil compaction caused by tractor tyres

Soil compaction caused by tractor tyres may seem to be a minor problem, but it has major repercussions on farm productivity.Impact on the crop root system

Soil compaction makes root growth more difficult. The roots of the crops don’t reach down to the deep layers of soil and have trouble finding the nutrients and moisture they need to grow.

A significant drop in production, of up to 50% in certain cases, is a direct consequence of this compaction.

Impact on the quantity of inputs

On top of the drop in yields, compaction also affects the efficiency of the inputs such as fertiliser and phytosanitary treatments which are less effective in compacted soil. This is compensated by a higher use of inputs, which leads to an increase in operating costs.

Increase in soil erosion

In addition, problems of erosion and run-off accentuate, preventing the land from being evenly irrigated and the conservation of water in the deep layers of the soil, which is essential during the dry period.

Drop in the quality of harvests

Lastly, soil compaction can also affect the quality of the produce harvested, particularly in the case of tuber crops. Soil that is too compact leads to the development of misshaped or irregular products, thus lowering their market value.

2. Expert opinion on soil compaction caused by tractor tyres

Hubert BOIZARD, expert at INRA (French national institute of agronomic research), has devoted nearly two decades to the study of soil.

His research, based on various crop systems and different tilling techniques, highlights the impact of soil compaction depending on different agricultural practices.

According to him, soil compaction varies significantly based on the weight borne by the tractor tyres and the working conditions:

- During light operations such as tilling and sowing, where the weight per axle is limited, use of low-pressure tyres can limit compaction, even with significant variations in soil moisture content.

- On the other hand, during harvesting, the bigger, heavier machines exert more pressure to the ground, thus increasing the risk of compaction, above all when working on wet ground.

Adapting tyres based on the work to be done

Hubert BOIZARD also points out that the risk of compaction varies depending on the cropping system. For example, with cereals, the impact is limited to around 15% of the field, whereas with beet, compaction may affect up to 100% of the surface area due to the weight of the beet harvesters.

These observations suggest that the choice and use of agricultural tyres must be adapted not only to the machine, but also to the type of crop and specific conditions of each farm.

3. Demonstration of soil compaction linked to tractor tyres

To visualise the impact of tractor tyres on soil compaction, tests have been carried out in real operating conditions. Here are the key results:

TEST 1 with a 8320 (320 CV) John Deere tractor fitted with 800/70 R38 VF VT-TRACTOR tyres:

- Pressure: 0.8 bar

- Result: low impact on the soil structure (compaction index 2)

- Advantages: conservation of the horizontal structure and crumbly nature of the soil, good infiltration of water

TEST 2 with a 6195M (195 CV) John Deere tractor fitted with 650/65 R42 Maxi Traction tyres:

- Pressure: 1.3 bar

- Result: moderate impact (compaction index 3)

- Observations: more compaction than for Test 1, the arable layer of soil is slightly more affected

TEST 3 with the same tractor and the same tyres as test 2 but with a pressure of 2 bar:

- Pressure: 2 bar

- Intensified impact on the soil up to 25 cm deep (compaction index 5)

- Consequences: vertical destructuring of the soil affecting the root system

TEST 4 with a 6190 (190 CV) John Deere tractor fitted with narrow 300/95 R52 Performer 95 tyres:

- Pressure: 4 bar

- Result: very high impact (compaction index 6)

- Effects: formation of compact clods of earth, significant deterioration of soil fertility

In conclusion, the use of high air volume tyres at a low inflation pressure (test 1) is the least damaging for the soil structure.

Inversely, an increase of the pressure in the agricultural tyres leads to increased compaction and deterioration of soil fertility.

These tests show the crucial importance of choosing suitable tyres to minimise the impact of soil compaction.

4. Soil conditions necessary to avoid compaction with your tractor tyres

Correct management of the state of the ground is essential if you wish to minimise the impact of tractor tyres on soil compaction.

Here are three types of soil condition to take into account before working in your field:

TYPE 1. Hard, compact ground

- Condition: hard ground, difficult to break up.

- Impact of machines: mechanical destruction of the soil, requiring decompaction.

- Tilling: very difficult without soil decompaction.

- Load bearing: maximum, all vehicles can circulate without worsening compaction.

TYPE 2. Light, crumbly earth

- Condition: soft soil, clumps that are easy to crumble.

- Tilling: ideal for tilling, with clods of earth which break apart easily.

- Load bearing: average, risk of rapid compaction if the machines are heavy or the tyres unsuitable.

- Advice: use low-pressure VF tyres (0.8 bar) to spread the load over a larger contact patch, thus limiting compaction.

TYPE 3. Moist, sticky earth

- Condition: waterlogged soil, very sticky and soft.

- Tilling: to be avoided due to soil destructuring under the weight of the machines.

- Load bearing: zero, deep soil compaction whatever the machinery used.

- Risks: slippage, soil sealing at the level of the furrow bottom, creation of ruts preventing crop development.

5. Why analyse the soil footprint of your agricultural tyres?

The footprint left by your tractor tyres is a key indicator which allows you to analyse the level of soil compaction easily. Here are the essential points:

The footprint is an indicator of compaction

The footprint left by the tyres is the visible reflection of a compaction related problem. It varies depending on the type of soil, the weather conditions, the tyre inflation pressure and the weight of the machine.

A footprint that is too prominent indicates a level of compaction that may require adjustments to protect the land and maintain future yields.

Weight distribution

Analysis of the footprint shows the distribution of pressure beneath the wheel. Radial tyres, with their flat tread, offer a more even load distribution than diagonal (bias ply) tyres which concentrate more pressure in the centre.

This weight distribution depends on the technology and internal structure of the tyre, which therefore have an influence on soil preservation.

Width, length and depth of the footprint

A deep footprint suggests excess compaction, which can accelerate erosion and prevent even irrigation of the land.

Reducing pressure in the tyres widens and lengthens the footprint, thus improving traction and minimising slip. This adjustment improves the weight distribution, making it less harmful to the soil and enabling a better transfer of traction power without damaging the soil.

Analysis of the soil footprint provides precious information which allows you to adjust tyre pressure and minimise the impact on compaction, thus improving the long-term health of the soil and crop productivity.

6. Protecting your soil against compaction during the harvest

Due to their size and weight, harvesting machines may pack down your soil significantly.

Here are a few strategies to minimise this impact:

Choose your tyres wisely

- Opt for IF (Improved Flexion) and VF (Very Improved Flexion) tyres which can carry heavier loads and spread the weight to the ground better.

- Adjust tyre pressure regularly during the harvest and check your soil footprint for an optimal distribution of weight to the ground.

Consider a more careful management of your soil

- Avoid entering a wet field to reduce the risk of compaction

- Consider harvesting early, if possible, to work in dryer conditions.

Try to reduce the load

- Reduce the load to the ground by avoiding transporting overloaded trailers.

- Empty the hopper regularly to minimise the impact to the ground.

Adopt a controlled traffic approach

- Control traffic by always following the same route to limit the impact to the ground.

- Controlled traffic farming using an RTK guidance system allows you to control vehicle work routes with an accuracy of within a few centimetres.

7. How do you rectify soil compaction after the harvest?

After harvesting, which increases the heavy machine traffic, soils can become extremely compacted.

Here are some ways to relieve this compaction:

Stubble ploughing

- Useful for preparing the topsoil.

- Burries straw residues to encourage their decomposition.

- Not very effective for deep restructuring after heavy vehicle traffic.

Tilling

- Decompacts the upper layers of soil.

- May create a compact plough pan, blocking water and roots.

Use a soil decompaction tool

- Breaks up the earth in the lower levels without turning it over.

- Helps to aerate the soil, to break the plough pan and encourage water infiltration.

excessivelycompressed soil

8. Which agricultural tyre helps to preserve soil fertility?

Controlling compaction is crucial in maintaining soil fertility.

Here are the conditions in which agricultural tyres can contribute to soil preservation:

Good management of load and pressure

- Avoid excess loads and overinflated tyres to limit compaction.

- Work on dry soil if possible to reduce damage.

Efficient transmission of power to the ground

- Use quality tyres to reduce rolling resistance.

- Ensure better distribution of tractive force, thus avoiding deep soil compaction.

Tight control of the slip ratio

- Maintain a good slip ratio to optimise traction without damaging the soil.

- Increase tyre size to obtain a wider soil footprint.

VF VT-TRACTOR agricultural tyres avoid soil compaction

- They have been designed to reduce compaction at the arable soil level.

- The unique structure of their casing means that they can work at very low pressure (0.8 bar).

- Their soil footprint is wider, which protects soil fertility and porosity.

- Their high load capacity allows them to work without affecting tyre efficiency or damaging the soil.

These special tyres help preserve the structure of the soil, allowing better aeration, good water retention and preserving the natural distribution of nutrients, while ensuring better protection of the arable layer of soil.

9. What technological farming innovations prevent soil compaction?

The latest innovations in the area of agricultural tyres, such as VF tyres and the Tank Air Wheel, offer advanced solutions to protect soils against compaction:

VF tyres combined with a CTIS

- VF (Very improved Flexion) tyres associated with a CTIS (central tyre inflation system) allow you to adjust pressure accurately based on the type of ground.

- This combination leads to better soil preservation and high agronomic yields.

- Excellent fuel savings are made thanks to pressure settings that are adjusted regularly.

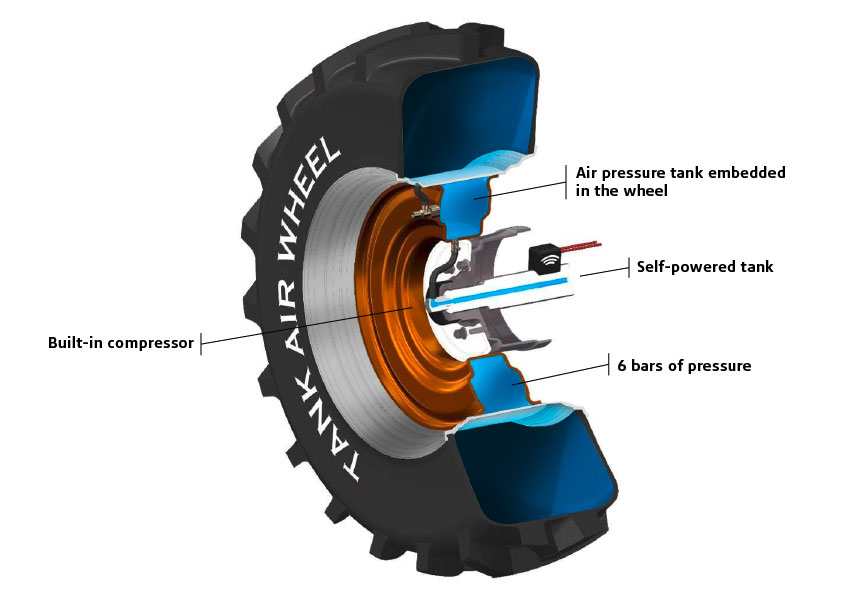

Pressure management innovation with the Tank Air Wheel

- Developed in partnership with Sodijantes Industrie, this innovative wheel rim contains an air tank with 6 bars of pressure.

- With remote inflation, this allows a very rapid tyre pressure adjustment, reducing the waiting time when you need to change from low to high pressure.

- Ideal for an efficient transition between working in the fields and driving on the road.

CONCLUSION

The importance of choosing your agricultural tyres well and using them correctly is vital if you wish to maintain your fields’ productivity and yields.

Among the solutions presented, Bridgestone’s VF VT-TRACTOR tyre stands out in particular. Thanks to its ability to work at a very low inflation pressure, this innovative tyre is an ideal solution for protecting soil integrity and significantly limiting the risk of compaction.

Use of this tyre brings major advantages to farmers seeking to optimise the health of their land while maximising their productivity and yields on a long-term basis.

The bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who can provide you with advice to help you achieve optimum productivity (Technical data on agricultural tyres - Agricultural tyre performance - Advice on agricultural tyre pressure - Soil compaction prevention - Sprayer tyre pressure - etc.)

To take it a step further and increase your farm’s profitability, the blog Bridgestone-agriculture.eu has prepared a free, highly detailed ebook which explains the essential role of the agricultural tyre on your productivity.

Most people who read this article have also read some of the following articles:

- How to reduce soil compaction after harvesting?

- What are the consequences of the soil compaction caused by my tractor tyres?

- 3 soil conditions to understand to avoid compaction by your tractor tyres

- What type of farming tyre is best for preventing ruts?

- Expert opinion on soil compaction caused by tractor tyres

- Demonstration of soil compaction linked to your tractor tyres

- Why analyse the soil footprint of your agricultural tyres?

- Which agricultural tyre helps you to preserve soil fertility?

- Technological farming innovations to avoid soil compaction

- Which agricultural tyre preserves the soil’s production capacities?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *