Over the last decade we have seen more and more technological farming innovations aimed at soil preservation. Technology is moving forward at a rapid pace, led by bigger, heavier and more powerful machines to improve productivity.

Tyres are part of this evolution, and all the systems that make it possible to adapt pressure in real time add further possibilities in terms of increasing the load and power without damaging the soil.

In this article we look at the main steps in the technological evolutions that allow us nowadays to preserve our soil and save time by increasing or decreasing the inflation pressure by more than 1 bar in a matter of seconds:

1st evolution:

The technical VF tyre evolution to avoid soil compaction

When using a standard tyre, you are faced with the problem of frequent changes in pressure when the type of ground changes.

If you choose not to change your pressure settings and to opt for an intermediate inflation pressure for all uses, the consequences will be greater than you expect:

High pressure in the fields:

excess slip = increase in fuel consumption

During work in the fields, especially in wet conditions, you are advised to reduce the inflation pressure in your tyres. Average pressure in standard tyres is too high on soft ground. This will lead to excess slip and a loss of traction despite your engine power.

The financial loss may end up being substantial in the long term, because the higher the slip rate, the more your fuel consumption increases.

High pressure in the fields:

Excess soil compaction = lower yields

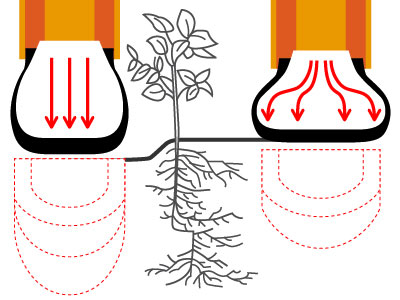

Among the main consequences of too much inflation pressure in the fields, excess soil compaction or compaction of the arable layer of soil are factors that should not be taken lightly.

Too much compaction blocks the circulation of air, water and the development of biological life in the different layers of soil, which considerably reduces crop growth in the long term.

Low pressure on the road:

more rolling resistance, longer braking distance

Unlike in the fields, you should increase your inflation pressure on the road to avoid excessive deflection of the tyre, especially when travelling at speed with a heavy load.

Too high an inflation pressure accelerates tyre wear but also increases the risk of losing control during sharp braking or causing instability when cornering…

Unsuitable pressure:

Decrease in tyre wear life = more frequent replacement costs

If you drive with too low an inflation pressure on the road, the tyre components will overheat at speed leading to rapid wear. On the other hand, too high an inflation pressure in the fields leads to excess slip, which also generates rapid wear to the tread.

Unsuitable pressure for the ground on which you drive your tractor therefore leads to premature wear to your tyres and increases the cost linked to replacing your tyres frequently.

VF technology: a real advantage when it comes to avoiding soil compaction

VF tyres have supple, reinforced sidewalls, making it possible to work at a very low inflation pressure (0.8 bar) despite the load. These tyres allow you to:

- Limit soil compaction and improve crop yields

- Preserve the biological life in your soil

- Protect your crops’ root system development.

with a pressure of 0.8 bar have less impact

on crop root development

VF technology: an important advantage for traction

VF tyres have an optimal traction capacity when working at low pressure, with a larger soil footprint.

The VF VT-TRACTOR tyre has Involute lugs which grip hold of the ground perfectly and limit soil displacement. This improves the tractor’s traction capacity, even on soft ground or in wet conditions.

A VF tyre such as Bridgestone’s VT-TRACTOR, offers many advantages:

- Less slip (Involute lugs)

- Better traction leading to a faster work rate

- Less wear (reinforced structure)

- Higher load capacity

- Lower fuel consumption linked to optimal traction

2nd evolution:

VF technology tyres with a remote inflation system

Opting for a remote inflation system is the next level up in tyre evolution, allowing you to adjust the inflation pressure during use.

This type of system improves VF tyre capacities and brings many advantages.

with Bridgestone’s VF VT-TRACTOR tyres

Precise pressure adjustments in the fields

Remote inflation systems allow you to adopt a much more suitable inflation pressure for all your uses, whether in the fields or on the road.

Connected directly to the tyres, the device is controlled from the tractor cab via an electronic control unit. Just one press of a button and the pressure is adjusted.

Soil preservation and yield optimisation

Very precise pressure adjustments on arrival in the fields will allow you to reduce the risk of soil compaction.

With remote inflation systems you can really adapt to actual conditions in real time; if the land is wetter in a given area, you can work at a different inflation pressure based on the soil conditions. This will lead to a high agronomic yield.

Fuel savings

Your fuel consumption depends on several factors: load, type of ground, weather conditions.

Driving with an inflation pressure that is perfectly adapted in all circumstances will lead to fuel savings:

- In the fields: a low pressure of 0.8 bar improves traction and reduces slip, which will lead to fuel savings.

- On the road: a pressure of 2 bar reduces rolling resistance which allows you to save up to 30% on fuel.

Reduction in tyre wear

The inflation pressure in your tyres will always be optimal thanks to the remote inflation system. On the road, the contact patch is reduced, while slip is limited in the fields.

If you systematically drive with tyres that are at the right inflation pressure, you limit premature wear and will therefore need to replace your tyres less frequently.

What is the advantage of a remote inflation system associated with VF tyres?

Combining a remote inflation system with VF tyres represents a perfect solution for optimising your yields.

If you opt for a VF tyre such as the VT-TRACTOR, you will have the possibility of dropping to a very low inflation pressure when necessary and transporting heavy loads at low pressure in the fields.

By combining a VF tyre with a central inflation system, you will be able to extend your tyre’s lifespan while multiplying the tyre’s soil preservation capacity.

However, there is still a problem remaining: When you don’t have a connected inflation system (additional compressor), what do you do to avoid waiting 15 to 20 minutes for the inflation pressure to be increased to protect your tyres when driving on the road?

3rd evolution:

2 technological farming innovations: Low-pressure VF VT-TRACTOR tyres together with the Tank Air Wheel at 6 or 7 bar

The VT-TRACTOR tyre was designed to work at very low pressure. Thanks to its supple yet reinforced sidewalls, it can work at as low as 0.8 or even 0.6 bar in certain cases.

Unlike standard tyres, this high-tech tyre has the ability to widen and extend its soil footprint at low pressure, for a better distribution of the load over a larger surface area, thus limiting soil compaction.

If you wish to protect your soil even further, either because you intend to work with bigger, heavier implements or because your land or your area is highly sensitive to soil compaction, you should combine these high-tech tyres with a suitable remote inflation system.

This will allow you to fine tune your pressure settings and have the right inflation pressure in all circumstances based on the land, the load and the weather conditions, which will allow you to protect your tyres against wear.

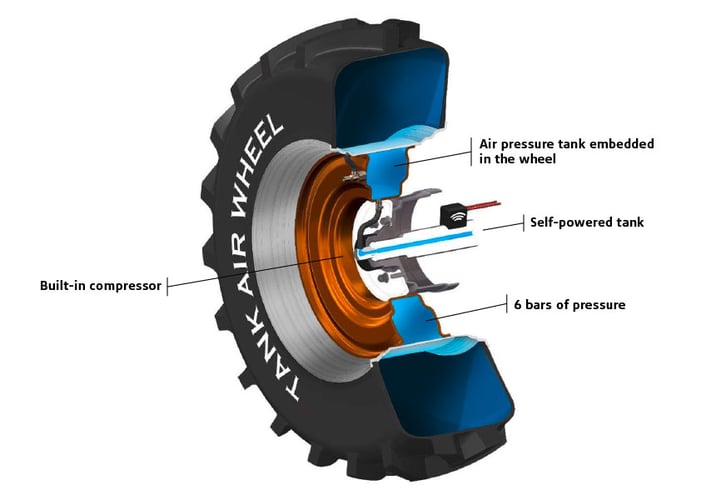

The Tank Air Wheel for a high pressure air tank

You can go even further and get rid of the air pressure adjustment waiting time. This is an optimisation which allows you to reduce wear even further and make your tyres last much longer.

Bridgestone has teamed up with Sodijantes Industrie to develop a new technological farming innovation

The Tank Air Wheel combined with a VF VT-TRACTOR tyre provides an optimal combination of technologies.

This new rim has been designed to store high-pressure air (using the compressor originally fitted in your tractor), which can be immediately available to gain 1 bar in pressure in a few seconds and allow you an optimal changeover to the road in terms of pressure.

The Tank Air Wheel is an air tank embedded directly in the wheel.

It contains hundreds of litres of air at 6 or 7 bar, which allows you to increase pressure almost instantly from 0.8 to 1.5 bar with large size tyres.

This technology allows you to adjust the pressure in your four tyres rapidly and simultaneously when you go from field to road without having to stop the tractor.

The Tank Air Wheel and the VF VT-TRACTOR tyre

A combination of technologies which gives you better control of the tractor:

Control of the slip ratio, better steering, better braking on the road…. in all circumstances, whatever the quality of the soil or weather conditions.

Testimonial of a farmer who has tested this technological combination

Gael Blard works on a 70 hectare farm, essentially growing specific crops: Open field tomatoes, sweet potatoes, garlic, herbs…. This type of crop requires a great deal of maintenanc and as such lots of vehicle passages.

The specificity of his farm is that it is fragmented, with fields spread over an area of 40 km, which means it can take up to 40 minutes to go from one field to another.

The difficulty with working in small fields is the frequent changes in inflation pressure between road and fields.

VT-Tractor tyres and Tank Air Wheel

Our tractors are equipped with Bridgestone VF VT-TRACTOR tyres, suitable for transport and heavy work in the fields.

These tyres are fitted on Tank Air Wheel rims which have an embedded air tank representing around 100 litres per rim, which when inflated to 7 bar will provide an air pressure reserve.

CONCLUSION

With today’s technological developments in the field of wheels and tyres, it is possible to increase loads and work with more powerful tractors.

You can continue to reduce soil compaction, have a better work rate and use less fuel while maintaining higher yields year after year in the same fields.

The bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who can provide you with advice to help you achieve optimum productivity (Technical data on agricultural tyres - Agricultural tyre performance - Advice on agricultural tyre pressure - Soil compaction prevention - Sprayer tyre pressure - etc.)

To take it a step further and increase your farm’s profitability, the blog Bridgestone-agriculture.eu has prepared a free, highly detailed ebook which explains the essential role of the agricultural tyre on your productivity.

Most people who read this article have also read some of the following articles:

- 9 major points on soil compaction linked to tractor tyres

- Protect your soil during harvest for successful sowing in the future

- How to reduce soil compaction after harvesting?

- What are the consequences of the soil compaction caused by my tractor tyres?

- 3 soil conditions to understand to avoid compaction by your tractor tyres

- What type of farming tyre is best for preventing ruts?

- Expert opinion on soil compaction caused by tractor tyres

- Demonstration of soil compaction linked to your tractor tyres

- Why analyse the soil footprint of your agricultural tyres?

- Which agricultural tyre helps you to preserve soil fertility?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *