Having powerful and sophisticated tractors, or high-capacity implements is not enough to really develop your productivity if you do not take into account the tyres which have an intermediary role between the machine and the ground, and allow you to make the most of your engine power. The tyre plays an essential role in the tractor’s overall efficiency and you must consider its capacities based on the technology and model chosen.

Each tyre has specific capacities and limits which you must use to the full to obtain a better yield. If underused, you will have efficiency losses or overconsumption of fuel and if overused, it will wear more rapidly or become damaged and require replacing.

In this article we look at the four main stress points for all your agricultural tyres which you must check to preserve your equipment and ensure an extended useful life.

1. Stress linked to the maximum TORQUE that your tyres can bear

What is the difference between torque and power?

To be able to draw your implements, your tractor must be able to transmit engine power to the ground. The power comes from the engine. Torque is the force of movement linked to acceleration. The tyre bears the strain of the torque, it does not supply the power, but must use the engine force to get the tractor moving.

The rotation of the engine transmits movement to the tyre, which acts as a lever between the tyre axle and the studs pressing into the ground.

The stress is therefore felt at the level of the tyre’s sidewall when you start the engine up and during acceleration.

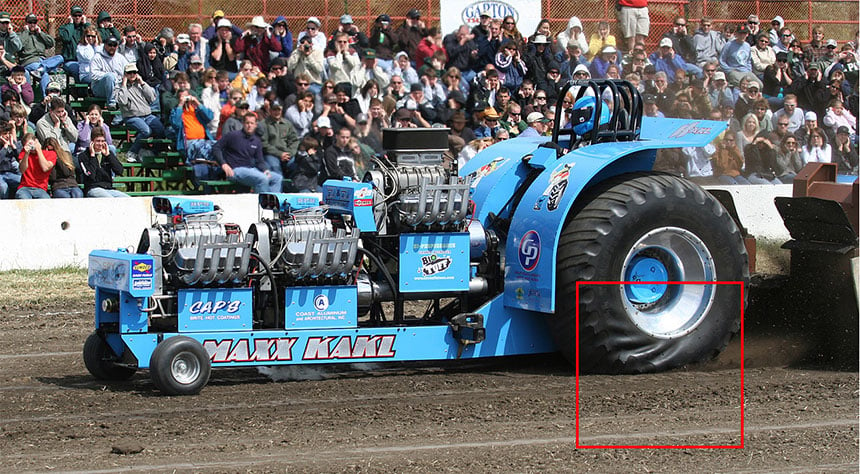

Visible example of sidewall deformation

Visible example of sidewall deformation

linked to excess torque on start-up during a pulling competition

At which moment is there the most torque?

Torque increases when an implement slows down the tractor.

As soon as the implement touches the ground, it slows down the tractor, the engine thrusts the tractor forwards, but the implement holds it back as the opposing forces do battle, and it’s the tyre which produces the compensation effort necessary to make the trailer move forwards.

This is all the more true when you work in the fields in wet conditions, at slow speed, in which case the torque will be high, requiring more tractive force.

In certain cases torque is not necessary

Inversely, traction is lower when you drive on the road at speed, and torque will be lower.

For example, for haymaking you need low torque, and for tilling high torque.

However, it is absolutely vital to check the maximum torque that your tyres can handle to prolong their lifespan.

Small tyres on a powerful tractor will weaken rapidly at the level of the sidewalls linked to excess torque, leading to fragility in the casing which could cause tyre damage.

2. Stress linked to the maximum LOAD that your tyre model can bear

Overloading is certainly one of the principal stress factors for an agricultural tyre. Failing to control load is taking the risk of damaging the structure of the tyre prematurely under the weight of the implements or trailers, and at worst, causing an accident on the road in the event that the tyre is damaged due to overloading.

Why should you check the load borne by your agricultural tyres?

In addition to the regulatory reasons, the power of your tractor or number of rolling axles, it is crucial to comply with the maximum authorised load to preserve your tyres and ensure they last longer.

Careful control of your load allows you to use your tractor’s capacity to the full and to work in the best possible conditions.

In certain cases it is possible to increase the load to work with heavier implements by adapting speed or pressure and in other cases by not increasing your load too much you can work quicker, avoid slip and preserve your tyres.

Checking the load with implements lowered, then raised

Checking the load with implements lowered, then raised

Excess load leads to premature tyre wear

Your tyres are crushed under the weight of the load. For standard tyres, this will have an impact on the internal structure of the tyre, if the sidewalls undergo too much deformation.

If you deliberately decide to reduce the inflation pressure in standard tyres to limit the effect of compression and avoid soil compaction, the heavy load will damage the internal structure of the tyre which will show weaknesses and then give way under the slightest strain, obliging you to change the tyre rapidly.

Cracks linked to excess load transfer

Cracks linked to excess load transfer

Normally, an excess load requires overinflation of the tyre, but this will lead to a loss of flexibility with the increase in pressure.

The tyre’s self-cleaning capacity will be reduced and earth will accumulate between the lugs, which leads to greater slip.

As a result, your overloaded trailer loses power, the tyres rotate faster than the tractor actually moves forwards, and wear increases in proportion to the slip ratio. Over several hectares, this situation has a real impact on wear and considerably reduces the lifespan of your tyres.

3. Stress linked to failure to comply with the specific inflation PRESSURE recommended for your agricultural tyre

In addition to torque and load, if it is not correctly adjusted, tyre pressure is one of the principal stress factors affecting your agricultural tyres.

Each category of tyre is designed for a particular, specific use, and failing to comply with the minimum pressure recommended by the manufacturer can cause premature damage to your tyre, which in the long run will lead to additional costs.

On the road: risk of overheating linked to underinflation causing additional wear

The road surface is very hard and abrasive, which is why it is not advisable to drive on the road with too low an inflation pressure.

An underinflated tyre’s ground footprint is bigger, which means that the contact patch between the rubber and the asphalt is larger.

With the increase in speed on the road, you mechanically raise the temperature of the tyre, which makes the rubber more supple and more vulnerable to the slightest obstacle.

The longer the distances you drive on the road with underinflated tyres, the greater and more rapid the risk of wear to your tyres.

The rise in the temperature of the tread

The rise in the temperature of the tread

will lead to rapid abrasion of the lugs

In the fields: risk of wear linked to overinflation to compensate for load

If you work with implements that are too heavy or you overload your trailers, you will have a tendency to boost inflation pressure to compensate for the excess load. On the road this is not a problem, but when you are working in the fields, the excess pressure will increase rolling resistance. The overinflated tyre sinks deeper into the ground, especially in wet conditions, leading to more slip and a more intense tractive effort which results in rapid wear to the tyres and, depending on the type of ground, visual damage to the lugs, as well as the sidewalls.

By adapting pressure to the extent of your load and the type of ground so that you always drive with the right inflation pressure, you avoid adding stress to your tyres. In this way, you can always work in the best conditions, ensuring better quality work and adding thousands of extra hours to your tyres’ lifespan.

4. Stress linked to the maximum SPEED that your tyres can bear when loaded

Agricultural tyres are designed to resist many different types of strain. Despite this, failure to comply with the manufacturer’s recommendations may lead to more rapid damage to your tyres, which is particularly true in terms of your tyres’ ability to cope with speed in certain conditions.

Abrasion linked to speed on the road

Abrasion linked to speed on the road

Why respect your tyres’ speed rating?

In addition to the safety aspect, tyre manufacturers have defined a speed rating to be respected for each type of tyre for a given load. This corresponds to the maximum speed to stick to when the tractor is loaded.

Basically it’s a question of the relationship between the load capacity of the agricultural tyre and its travelling speed to ensure the preservation of the tyre’s constituent materials while extending its lifespan.

In the same way as the load index, the tyre size or date of manufacture, the speed rating is marked on its sidewall, directly after the maximum authorised load. Depending on the model, this index may be expressed in letters:

For example you can read on the tyre below the marking “171 A8 “: A8 is the speed rating, which corresponds to a maximum speed of 40 km/h for a load index of 171.

Load index and speed rating marked on the tyre sidewall

Load index and speed rating marked on the tyre sidewall

Quality tractor tyres are designed using resistant and efficient materials to resist numerous types of stress factors on the road and in the fields, even during intensive use.

However, there are limits to the strains that tyres can bear and their lifespan will depend on the conditions in which they are used, considering in particular:

- Load,

- Pressure,

- Speed,

- Type of ground.

All these factors have a major influence on the resistance of the rubber that the agricultural tyre is made of, and thus on its deterioration.

By driving on the road at high speeds, which is to say faster than is recommended by the tyre manufacturer, you run the risk of overheating the rubber used to make the tread. This damages the internal structure of the tyre and may lead to damages or cause an accident if the tyre bursts following overheating.

When you drive on the road, the tread is placed under great strain, with temperatures within the tyre reaching up to 65° if you exceed the speed limit and the load recommended by the manufacturer.

On the road, make sure that you comply with the speed rating corresponding to your load and inflation pressure to avoid damaging your tyres too rapidly. Refer to the table supplied by the tyre manufacturer to determine the maximum recommended speed.

If you wish to extend your tyres’ lifespan, the best advice is to comply with all the information provided by the manufacturer.

To learn more about ways to increase your farm’s productivity, bridgestone-agriculture has created a comprehensive eBook on the topic which is available for you to download for free:

Bridgestone-agriculture Blog is written and administered by tractor tyre experts who are available to provide you with advice on agricultural tyres. They will help you to maximise your productivity with information on all things relating to tyres: inexpensive tractor tyres, technical data for agricultural tyres, solutions for avoiding soil compaction, sprayer tyre pressure, why and how to ballast your tractor tyres, when to use dual-wheels, the mechanical causes for abnormal wear, discounted agricultural tyres, etc.

Most people who read this article have also read some of the following articles:

- 10 tips to reduce abnormal wear to your farming tyres

- Why do my front tractor tyres wear much quicker?

- How to limit agricultural tyre wear faced with heavy loads

- When does a split make it necessary to replace your tractor tyres?

- Testimonial: are there agricultural tyres more resistant to wear?

- Can a hernia on my tractor tyre be repaired?

- Repairing tractor tyres: the techniques for each situation

- When can you carry out cold repairs on tractor tyres?

- 5 problems on the bead of an agricultural tyre which mean it has to be replaced

- Does unsuitable inflation pressure accelerate wear to my agricultural tyres?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *