Changing a set of tyres represents a significant investment, so you are entitled to wonder why your tyres do not last as many hours as you expected. It is quite easy to make a critical judgement on the brand of tyre, considering that it’s a question of product quality. However, the number of hours that tyres can last depends on production quality of course, but more often it is a question of the use you make of them.

Each tyre has been designed for a specific use and it’s often when you move outside the scope of use defined by the manufacturer that wear accelerates. But rest assured, you can increase the lifespan of your tyres if you choose the right model which corresponds precisely to your farm and your operations.

Here are the different reasons why our agricultural tyres may not last the number of hours expected:

Use of the same model of tyre will not represent the same number of hours of work for all users. The reason is simple; apart from the production quality, there is not just one cause that accelerates wear, but rather a set of circumstances and combined factors which may be involved in the level of wear reached after 1000, 2000 or 5000 hours of work.

Here are the most important points to know for efficient management of tyre wear and the number of hours that your tyres can work.

1. On what type of land do you use your tractor tyres?

Apart from its implements, your agricultural tyres are the main point of contact between your tractor and the ground, which is why the ground is so important in terms of the lifespan of your tyres.

To find out whether your type of land is one of the causes of premature wear, ask yourself the right questions when changing your tyres:

What is your farm land like?

Whatever the configuration of your farm, you will use your tractors on different types of ground: the court farmyard, the road or pathways, then your fields where the earth will be different depending on the region.

Each type of ground may have an impact on tractor tyre wear and it would be wise to choose the tyre model which is best suited to your type of soil:

- Loam, sandy or silt/clay soils will not lead to rapid wear.

- Limestone soil may be a cause of wear depending on the quantity and granulometry of the limestone particles.

Limestone soil

Limestone soil

- Stony or silex soil, very rich in different types of rocky particles, may cause numerous scratches or cuts on the lugs.

- Sloping land, whatever the type of soil, will result in a higher tyre slip ratio and therefore require a greater level of motricity.

- Wine growing land is often very hard with many flush rocky particles, granite, schist and limestone rock which can case accelerated wear.

Lugs covered in cuts and scratches

Lugs covered in cuts and scratches

linked to use on soil rich in silex

Do you frequently use your tractor for transport by road?

Agricultural tyres are designed for work in the fields and not for intensive use on the road. However, more and more tractors have to cover many kilometres by road due to the distance between fields.

When you drive on a dry tarmac road, you should expect to see more rapid wear to the tip of the lugs because the road surface is highly abrasive for agricultural tyres.

By driving slowly, you limit this wear because the slip ratio on the road is low.

On the other hand, if you drive faster, there will be much more tyre slippage. This will inevitably lead to a rise in the temperature of the rubber, making it softer and therefore more sensitive to abrasion.

Abrasion of the lugs linked to speed on the road

Abrasion of the lugs linked to speed on the road

Do you regularly drive on paths or secondary roads?

You must take into consideration the condition of the secondary roads on which you drive, the often limited width of these routes as well as their sloping edges.

If you drive frequently on crowned paths or roads with deformations or holes, your tyres will wear irregularly to a more or less pronounced extent.

Each impact or shock due to sones, obstacles or a deteriorated roadside may alter the rubber and the lugs of your tyres.

Do you frequently come across ruts?

Ruts may also have an impact on the lifespan of your tyres. When you drive frequently in ruts that are too deep, the wheel axis may become slightly off-kilter.

Over time, driving over ruts can lead to problems with wheel geometry and parallelism.

When your tyres are no longer parallel, they are more prone to rapid, abnormal wear.

2. What are your habits in terms of use of your tractor tyres?

Tractor tyre wear also depends on your user habits.

- How often do you adjust pressure?

- Do you check your load regularly?

- Do you respect the speed limit that corresponds to your load?

- Do you check mechanical settings (parallelism and wear to the axles)?

Any use that is non-compliant with manufacturer recommendations is likely to accelerate wear.

How do you manage pressure checks?

Increasing inflation pressure to compensate for the weight of the implements is a good thing, yet working in the fields with a high tyre inflation pressure is unadvisable and will increase the slip ratio, in particular on loose soil and in wet conditions.

The higher the pressure, the more the tyres are likely to sink into the ground, causing extra fuel consumption linked to slippage and leading to premature tyre wear.

On the other hand, reducing the pressure in your tractor tyres when you work in the fields will help you to preserve your soil. Yet for the road, this is not the best option, above all if you transport heavy loads. There are many disadvantages to underinflated tyres:

- If you opt for a pressure below what is recommended by the manufacturer, the outside of the sidewalls will be flattened onto the ground just like the tread, and a minor obstacle (branch, root, stone…) may cause a sudden puncture.

- A tyre that is frequently underinflated does not keep its original shape, leading inevitably to a progressive deformation of the casing. The overall structure of the tyre will present weaknesses, wear may appear at the level of the casing reinforcement on the edge of the rim due to excess flexion of the sidewalls.

If you do not adapt pressure when you go from field to road, the lifespan of your tyres may be reduced by 25%. On the road, an underinflated tyre heats up more rapidly with speed, damaging the rubber and accelerating wear.

Do you check load distribution?-What happens if you have too much front ballast or an implement that is too heavy at the rear?

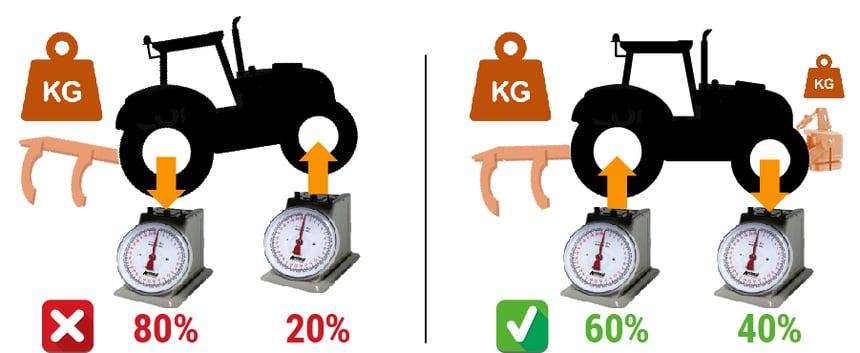

Heavy loads are one of the causes that accelerate agricultural tyre wear. They cause strain at the level of the casing and the tread of the tyre, which can cause permanent deformation and premature wear. It is therefore advisable to spread the load on the basis of 40% at the front and 60% at the rear.

This reduces the risk of slippage in the fields and makes tyre wear more even.

A good load distribution to reduce tyre wear

A good load distribution to reduce tyre wear

Do you use implements that are adapted to your tyres?

When you install heavy implements or overload your trailer, the weight of your combination vehicle will crush your tyres.

Although agricultural tyres are designed to carry heavy loads, you must take care not to go beyond the manufacturer recommendations in terms of load index, i.e. the maximum load on each axle and the maximum speed when loaded.

There are more sophisticated low-pressure tyres that have been designed to bear heavier weights and that have a deformable casing which is much more resistant than standard tyre models.

3. Are the technical characteristics of the tyres adapted to your farm?

Not all tyres have the same production quality or quality of components. Radial tyres are more suitable for farm work than bias-ply tyres which are better for work on hard ground, site work or work in quarries.

The level of technology is vital in the fight against wear, VF technology tyres having effectively been designed to adapt perfectly to agricultural work by taking into account the specific requirements of your activity.

What types of tyre are more suitable for use with field crops to avoid wear?

If you work essentially with field crops, you should opt for tyre models that can help you optimise production, such as VT-TRACTOR tyres which have many benefits:

- Optimal traction

VT-TRACTOR tyres offer better traction thanks to a very large soil footprint, up to 26% bigger than the competition. They guarantee faster work and allow you to cover nearly 1 ha more ground in one day. This wide soil footprint limits slippage and the resulting wear. - Greater load capacity

The VF construction of the structure of this tyre is much more resistant, which gives it a load capacity of up to 40% more than a standard tyre with the same speed and inflation pressure. A good solution if you want to avoid wearing your tyres when your implements are too heavy. - Versatility and time saving

They have casing that is more supple and resistant to wear. You will save a great deal of time when going from field to road because you no longer need to adjust inflation pressure.

What types of tyre are better suited for use in polycropping and livestock farming or for mixed use?

Bridgestone’s VX-TRACTOR tyres are perfectly suited to polycropping and livestock farming or more generally for mixed used, in the fields, in the farm courtyard and for transport.

Measuring wear on VX-Tractor tyres

Measuring wear on VX-Tractor tyres

Here are the advantages of this tyre model:

- Up to 20% more rubber

VX-TRACTOR tyres have a thicker tread and deeper rubber lugs which offer optimal traction in the fields while ensuring a longer lifespan. - A wear-resistant rubber compound

The type of rubber is crucial and these tyres are designed with specific materials, such as vegetable oil which increases resistance to wear.

To learn more about ways to increase your farm’s productivity, bridgestone-agriculture has created a comprehensive eBook on the topic which is available for you to download for free:

Bridgestone-agriculture Blog is written and administered by tractor tyre experts who are available to provide you with advice on agricultural tyres. They will help you to maximise your productivity with information on all things relating to tyres: inexpensive tractor tyres, technical data for agricultural tyres, solutions for avoiding soil compaction, sprayer tyre pressure, why and how to ballast your tractor tyres, when to use dual-wheels, the mechanical causes for abnormal wear, discounted agricultural tyres, etc.

Most people who read this article have also read some of the following articles:

- 10 tips to reduce abnormal wear to your farming tyres

- When does a split make it necessary to replace your tractor tyres?

- Testimonial: are there agricultural tyres more resistant to wear?

- Can a hernia on my tractor tyre be repaired?

- Repairing tractor tyres: the techniques for each situation

- When can you carry out cold repairs on tractor tyres?

- 5 problems on the bead of an agricultural tyre which mean it has to be replaced

- Does unsuitable inflation pressure accelerate wear to my agricultural tyres?

- What are the 4 top stress factors for your agricultural tyres?

- What impact does stubble have on my tractor tyre wear?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *