You are aware that lead plays an important role in the efficiency of your tyres and that failing to take this aspect into account has consequences in terms of the behaviour of your tractor at work.

However, it is not easy to spot incorrect lead, as this is certainly one of the most difficult mechanical settings to grasp.

For 4WD tractors with different size wheels, the lead ratio is linked directly to the circumference of the wheels and the tractor’s drive ratio.

To help you determine if the irregularities you have noted in the behaviour of your tractor are linked to lead, this article looks at the principal signs that will allow you to tell whether this setting is optimal on your tractor.

1. What are the advantages of having a good lead ratio?

To understand why it is worth checking the lead ratio whenever you replace a set of tyres, here are the advantages that you will obtain with an optimal lead ratio:

Better energy efficiency

On a four-wheel drive tractor, the front wheels must turn slightly faster than the back wheels to obtain a slight pulling effect and ensure the correct functioning of the different mechanical components of the tractor: engine, transmission, differentials… It’s this difference, expressed as a percentage that is known as the ‘lead ratio’.

To obtain the perfect synchronisation between the front axle and the rear axle, you must check the lead ratio when you change a tyre. Generally, the accepted tolerance is between 0.5% and 5%. But ideally, the closer you get to 2.5% the better it is for optimal traction. If this ratio is spot on, you will improve the energy efficiency of your tractor and save on fuel.

Longer tyre life

Differences in speed of rotation between front and rear axles may increase wear to the tyres.

A good lead ratio allows you to extend the lifespan of your tyres. An optimal ratio is between 1.5% and 3% but the closer you get to 2.5%, the more you reduce wear to the lugs, thus extending the potential lifespan of your tyres.

Better grip

The agricultural tyre is the link between the tractor and the ground, its lugs grip the earth to transmit torque and make the tractor move forward.

To obtain good traction, you need lugs that grip hold of the ground efficiently with a controlled slip ratio.

Several factors have an impact on grip; weather conditions of course, but also inflation pressure, tyre wear and lastly the lead ratio.

Optimal lead settings, with a ratio of around 2.5%, ensure perfect traction for your tractor.

2. What type of wear can be the sign of incorrect lead?

If you notice irregular wear to the front tyres, this can be the sign of an incorrect lead ratio.

The front axle is always the most impacted if the lead ratio is too high or too low. There are two possible scenarios: either the front axle slows down the tractor too much or it pulls too strongly.

A high lead ratio, generally above 5%, is a sign that the front tyres are pulling much too strongly compared to the rear tyres. You will see wear to the trailing edge of the lugs like sharp knife blades.

to the rotation speed of the front tyres being too high

3. You notice excessive slip at the front

You have noticed excessive slip at the front of the tractor. It is quite possible that your lead ratio is too high (above 5%).

In this case, the front tyre which is pulling too strongly tends to sink into the ground if the soil is soft, or slip if the weather conditions are poor.

If you do not modify the configuration of your tyres, you will lose efficiency at the level of traction due to the slipping of the front tyres.

The consequences may be multiple, for example:

- Considerable loss of time on each campaign: the number of hours increases with the level of slippage

- Up to 20% more fuel consumption

- Premature tyre wear: the lugs are placed under considerable strain and wear rapidly.

4. You have mechanical transmission problems

Too low a lead ratio, although still positive (close to 0.5%) will not allow you to make full use of your tractor’s 4 drive wheels, so traction will not be optimal.

On the other hand, if the lead ratio is below 0.5% or negative (lag) the rear axle will have a tendency to push the front axle. In this case, the front axle no longer pulls but slows the tractor down.

Among other problems, this will lead to a mechanical heating of the front hubs, as well as additional slippage at the rear. This lag creates stress at the level of the powertrain and the front axle is placed under too much mechanical strain.

You can see this problem when braking on the road, when the front axle engages automatically, you hear a clicking noise at that moment. The repetition of this clicking will wear the gear train pinion and require repairs and mechanical costs which could have been avoided.

By driving in these conditions, you run the risk of seriously damaging your tractor’s transmission as well as its mechanical components such as pinions, reducers, differentials, etc.

5. You have different tyres on the front and rear axles

If you use two different tyre brands on the front and rear axle, your lead ratio may be wrong even with the right tyre dimensions. The reason for this is that the circumference of the tread may be different depending on the height of the lugs if you use different brands of tyre.

ETRTO standards make it possible to have similar dimensions between brands for the width, the height of the tyre or size of the rim, but unfortunately not for the circumference of the tread which may be different.

As the lead ratio is calculated based on this circumference, there is a risk of moving out of the right lead ratio bracket quite easily.

Mixing tyre brands between the front and rear axle is therefore not recommended when you replace your tyres.

Different tyre technology for the front and rear tyres should be avoided

The problem is the same if you use different technologies.

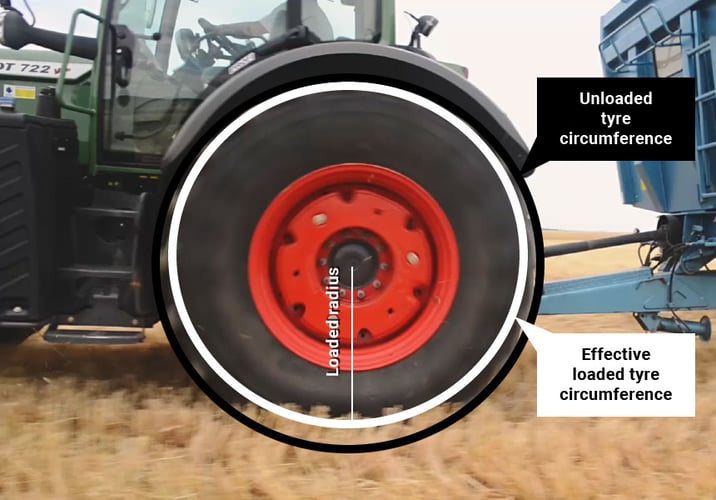

If you compare standard tyres at the front with VF tyres at the rear (even if the dimensions are correct in theory), the front tyres won’t be as supple, so the loaded radius will be different.

This can have a negative impact on the lead tolerance width.

With heavy loads, the deflection capacity will be different between the two technologies, with the extensive deflection capacity of the VF tyres modifying their effective rolling circumference and completely distorting your lead ratio.

6. You have just replaced your front or rear tyres

When you replace tyres it is necessary to take wear into account in calculating the lead ratio. If you change the rear tyres, there will be a major difference between the new tyres at the rear and the half worn tyres at the front. The same applies if you change the tyres on the front axle.

The lead ratio calculation is closely linked to the tyres’ rolling circumference, so if this changes for any reason the lead ratio will inevitably be affected. This can cause operating anomalies.

As long as your front tyres wear at the same speed as your rear tyres, the lead ratio settings will maintain their balance and should be more or less identical for the entire lifespan of your tyres.

So when you replace tyres, you must recalculate the correct lead ratio and not systematically remount tyres with the same dimensions.

An incorrect lead ratio can have very negative consequences on your work: difficulties with the handling of the tractor, excess slip, rapid wear, mechanical problems.

So when you replace your tyre it is very important to choose the tyre model which will allow you to obtain a lead ratio of as close to 2.5% as possible, as this is the perfect fit.

There will be a real difference, as with the front and rear axles perfectly synchronised, your 4 tyres will work together, traction will be better, slip reduced and fuel consumption lower.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Cheap tractor tyres — Technical data for agricultural tyres — Air pressure advice — Solutions to avoid soil compaction — Sprayer tyre pressure — Why and how to ballast your tractor tyres — When to use dual wheels — The mechanical causes of abnormal wear — Cheap agricultural tyres – etc.

To learn more and boost your farm's profits, Bridgestone-Agriculture is offering you a free, detailed white paper that explains the essential role your agricultural tyres play in your productivity.

Most people who read this article have also read some of the following articles:

- 5 essential techniques to optimise your agricultural tyres

- Impact of the loaded radius for my agricultural tyres

- VF agricultural tyres versus caterpillars: Pros and cons

- Why should you check your harvesting tyres before the start of the harvest?

- Which agricultural tyre makes it possible to avoid coming off the rim at low pressure?

- What is the impact of implement settings on tractor tyres?

- Fleet audit: what is the main benefit of agricultural tyres?

- Do you really use the full capacity of your VF agricultural tyres?

- Agricultural tyres: rules for managing the lead ratio

- Managing the load transfer to the front tyres in polycropping

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *