You have decided to buy used tyres to reduce costs, which is a rational choice to replace a set of tyres with a limited investment.

Here is some advice on how to evaluate a used tyre and establish whether this is the best choice for your farm on a long-term basis.

1. How to make the right choice of tyre when it’s time to replace them

The replacement of agricultural tyres is based on several factors, irrespective of the price, to continue to farm safely, effectively & efficiently, and to avoid technical problems and above all try to improve your productivity.

Here is some basic advice to avoid problems:

Do not mix up technologies: standard tyres, IF and VF tyres

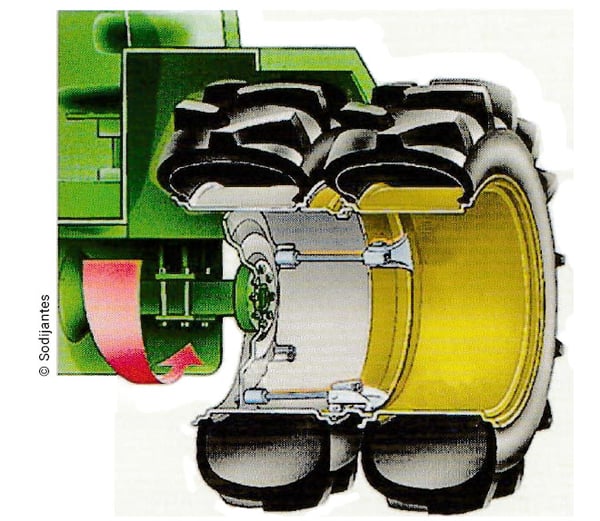

In recent years, several construction technologies were developed for agricultural tyres. such as IF and VF tyres, which are significantly different than the conventional ’standard’ tyres.

As they have different sidewall deflection characteristics, these tyres behave differently under equal load or same inflation pressure. In addition, tyres incorporating recent technologies effectively have different load capacities. So you shouldn’t combine them on your vehicle, because this has a major influence on stability, vibrations, geometry and can lead to mechanical problems.

The tyres must be mounted in accordance with basic rules.

In the case of a single tyre replacement: you must opt for a new tyre that is the same as your current model. Not only is it preferable to have the same degree of wear to both tyres on the same axle, you should also have:

-

- The same brand

- The same dimension

- The same manufacturing structure: radial, diagonal or bias belt.

- The same pattern

- The same technology

In the case of duals: they must have exactly the same outer diameter. Make sure that you never mount tyres with a larger diameter when twinning, which can result in mechanical breakdown at the level of the axle hub.

Respect the tyre’s load and speed rating

Never exceed the load and speed indexes that are marked on the sidewall of the tyre.

You must therefore choose a replacement tyre that can bear the same load on the same axle to avoid any imbalance or reduce the overall capacity of your vehicle if you choose a tyre with lower indices.

Please remember that in case of a dual fitment, the inner and the outer tyre maximum load is 88% versus single fitment. Putting 2 tyres next to each other allows 88+88=176% of a single load; not 200%.

2. What are the traps to avoid?

Used tyres are cheaper to purchase but may conceal a number of traps.

Here are a few tips to help you identify a bad product and get on with the job:

- Heavy wear to the lugs: the tyre has less remaining tread depth tread depths, which means that it has already been in use for years and won’t last much longer. Even if they are not expensive, avoid this type of tyre to avoid the risk of the weakened casing breaking definitively, puncture or immobilisation.

- Scratching on the tread: if there are many scratches on the lugs which are still thick, but with no deep cuts on the sidewall or inner tread structure, you can certainly buy the tyre, but its use in the fields will be less efficient. Lugs that have become worn and smoothed down over time will effectively have a lower traction capacity.

- Scratching of the inner tread structure only: if the lugs size is still good and you do not see any major cuts on the sidewall, but only light cuts on the inner tread structure, you can buy the tyre, it will not present any specific problem.

- Deformation on the tyre sidewall: this may be caused by a violent lateral impact to the sidewall, it is not advisable to opt for this type of tyre because there might be a major weakness to the body plies which may fail at any time (long trip on the road, high tyre pressure, heavy load…).

- Deterioration of the tyre bead: in this case, buying the tyre is not recommended, as it will be difficult to mount on your tractor. There will be a real risk of breaking the bead during mounting or inflation which could lead to an explosion resulting in serious injury for the person carrying out the operation.

- Breaks in the tyre’s internal innerliner: these are generally due to inappropriate use of the tyre (failure to respect inflation pressure, driving with a flat tyre or excessive loads). Even if the outside appearance of the tyre is excellent, its interior structure presents real weaknesses, probably making it unusable very rapidly.

- Cuts at the base of the tyre lugs: this means that the tyre has worked a lot, either on a very hard surface or under very severe torque conditions, often at the limit of its load capacity and is showing signs of strain, so it’s not worth wasting your time even if the remaining lug depth is still good.

- Breaks in the rubber at the level of the shoulders: are a sign that the casing has been overloaded or intensively underinflated, making the tyre rapidly unusable.

- Please look at the DOT of the tyre: EVERY tyre has a DOT number on the tyre. When the DOT has been removed, it means that the tyre was analyzed by a manufacturer expert and should be taken out of use.

For safety reasons and for peace of mind, you need to be very prudent when buying second-hand tyres and not be influenced by an enticingly low price.

3. How to calculate the discount to apply to a second-hand tyre

The value of an agricultural tyre is based on two factors:

- Its age: the year of manufacture is indicated on the sidewall.

- Its wear rate: this can usually be measured by the remaining tread depth. To estimate wear, refer to the original tread depth of a new model, which may be from 35 to 65 mm depending on the tyre model and size.

Calculating the discount

- Original tyre: a fixed 10% discount should be applied to the selling price of a common new tyre and 15 to 20% for an uncommon tyre.

- Second-hand tyre: the height of the lug must be measured, given that the minimum height before being totally worn is 10 to 20 mm.

Additional discount

- Unknown tyre brand

- Dry, scratched, asymmetrically worn tyre …

- Very old model, no longer available on the market.

Calculating the rate of wear

To calculate the rate of wear, the magic formula is as follows:

Rate of wear (%) = 100 – (height of used lug x 100/height of new lug – 10 mm)

Example to illustrate this calculation formula

We will estimate the price of a standard tyre 710/70R38 costing €1,250 new with a lug height of 55 mm new, and a used lug height of 20 mm.

- Rate of wear = 100 – (20 x 100 / 55-10) = 44%

- Second-hand value = 1250€ x 44% = 550€ - additional discount (cuts or other)

4. What does tyre ageing correspond to?

All agricultural tyres age over time even if they are only used occasionally. Numerous factors contribute to this ageing process.

- Physical ageing: linked to the use, flexion, deflection, load or other, this may take the form of cracks in the rubber of the tread or sidewalls.

- Chemical ageing: this is the degradation of the structure under the effect of chemical products such as hydrocarbons or solvents.

- Thermal ageing due to lack of oxygen: deprived of oxygen in the presence of oil or water, the tyre becomes softer as a result of high temperatures (exposure to the sun).

- Ageing due to ozone exposure: the protective action of the antioxidant package in the rubber compound tends to reduce its effectiveness by time.

- Ageing due to exposure to sunlight: the rubber does not react well to prolonged exposure to UV rays, leading to the appearance of small cracks on the surface of the tyre.

5. How can used tyres impact your productivity?

The renewal of your agricultural tyres represents a considerable investment, which is why a good number of farmers decide to wait and get the most from their old tyres. However, waiting too long to replace your tyres is not always as profitable as you might think. On the contrary, the use of worn tyres can have a major impact on your productivity.

Worn tyres affect your working time

The use of worn tyres will make you lose time, because their lugs have been shortened due to wear and their traction capacity in soft / wet soil is reduced and slip rate increased.

Worn agricultural tyres reduce productivity

Excessive slip percentages resulting from the use of worn tyres inevitably alters your soil, use more fuel and will have a major negative impact on yields, which may be reduced by 10 to 30% depending on the crop and type of soil.

Worn tyres may result in unexpected production stoppage

Worn tractor tyres are more fragile and are less resistant to punctures / impacts. A breakdown during intense periods such as seeding or harvesting will inevitably lead to a loss in yield.

If you want to keep optimal productivity, using tyres that are in good condition is certainly the best solution.

6. Does it make sense economically to choose a VF tyre rather than a second-hand tyre?

There are numerous advantages to VF technology (Very improved flexion) tyres, even if they are more expensive to buy, they allow you to make recurrent savings in the long-term, on the following points:

- Savings in terms of working time: VF tyres have a specific construction that allows a high degree of sidewall flexing, so that a big footprint is obtained at low inflation pressure. This increased tyre footprint distributes the applied load over a bigger surface (which is beneficial for soil health) and the vehicle will operate under lower slip rate which means a gain in operating time.

- Fuel savings: VF tyres allow you to save up to 0.7 litres of non-road fuel per hectare compared to a standard tyre. If you are covering several hundred hectares, the savings will be considerable.

- Savings in terms of operating losses: by opting for a VF tyre, you will have the possibility of optimising productivity (low pressure, heavier loads, larger soil footprint = soil preservation…).

- Savings in maintenance and repairs: these latest generation tyres are designed with quality materials that are more resistant to different forms of external aggression. Thanks to this, they will be with you for a longer number of years, depending on the type of use.

The Bridgestone-agriculture.eu blog is written and administered by tractor tyre experts who are available to provide you with the advice you need on the subject of your agricultural tyres. They allow you to maximise your productivity with information on all subjects linked to tyres: Technical data for agricultural tyres – Agricultural tyre performance – Air pressure advice, Solutions to avoid soil compaction – Sprayer tyre pressure – Why and how to ballast your tractor tyres – etc….

To take it one step further and increase the profitability of your farm, les Experts du pneu provide a free, highly detailed eBook which explains the essential role of the agricultural tyre in your productivity.

Most people who read this article have also read some of the following articles which are listed by order of popularity:

- Buying guide: 10 important tips for choosing the right farming tyres

- 4000 euros in savings per year by chosing a better agricultural tyre

- How to choose tyres for my farm trailer before the harvest?

- Standard farming tyre or forestry tractor tyre for deforestation?

- Which is better value? A cheap agricultural tyre or a VF tractor tyre

- Here’s how your agricultural tyres can save you money

- How to make the right choice for your agricultural or tractor tyres?

- Increase the yield of your sprayer with narrow VF tyres

- Do you know which are the best agricultural tyres for your sprayer?

- A good agricultural tyre is the best guarantee of sprayer stability

- What is the best tyre for my combine harvester, IF, VF or CFO?

- A hi-tech agricultural tyre to save time during your harvest

- The top 5 reasons for choosing VF agricultural tyres

- The VF agricultural tyre: VF technology increases your productivity

- Cheap agricultural tyres, discount agricultural tyres, is it worth it?

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

Leave a

commentary

Your email address will not be published.

Required fields are indicated with *